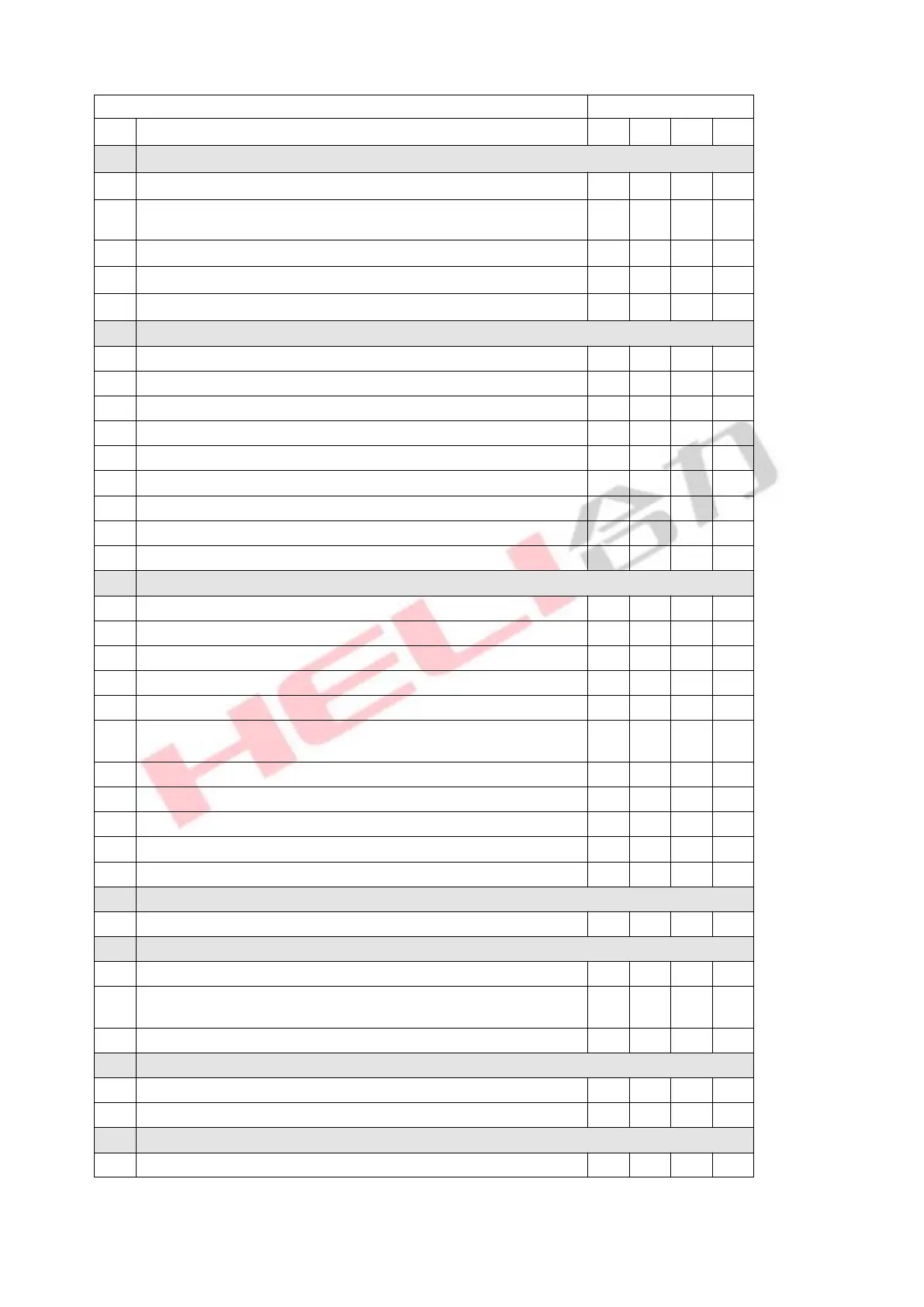

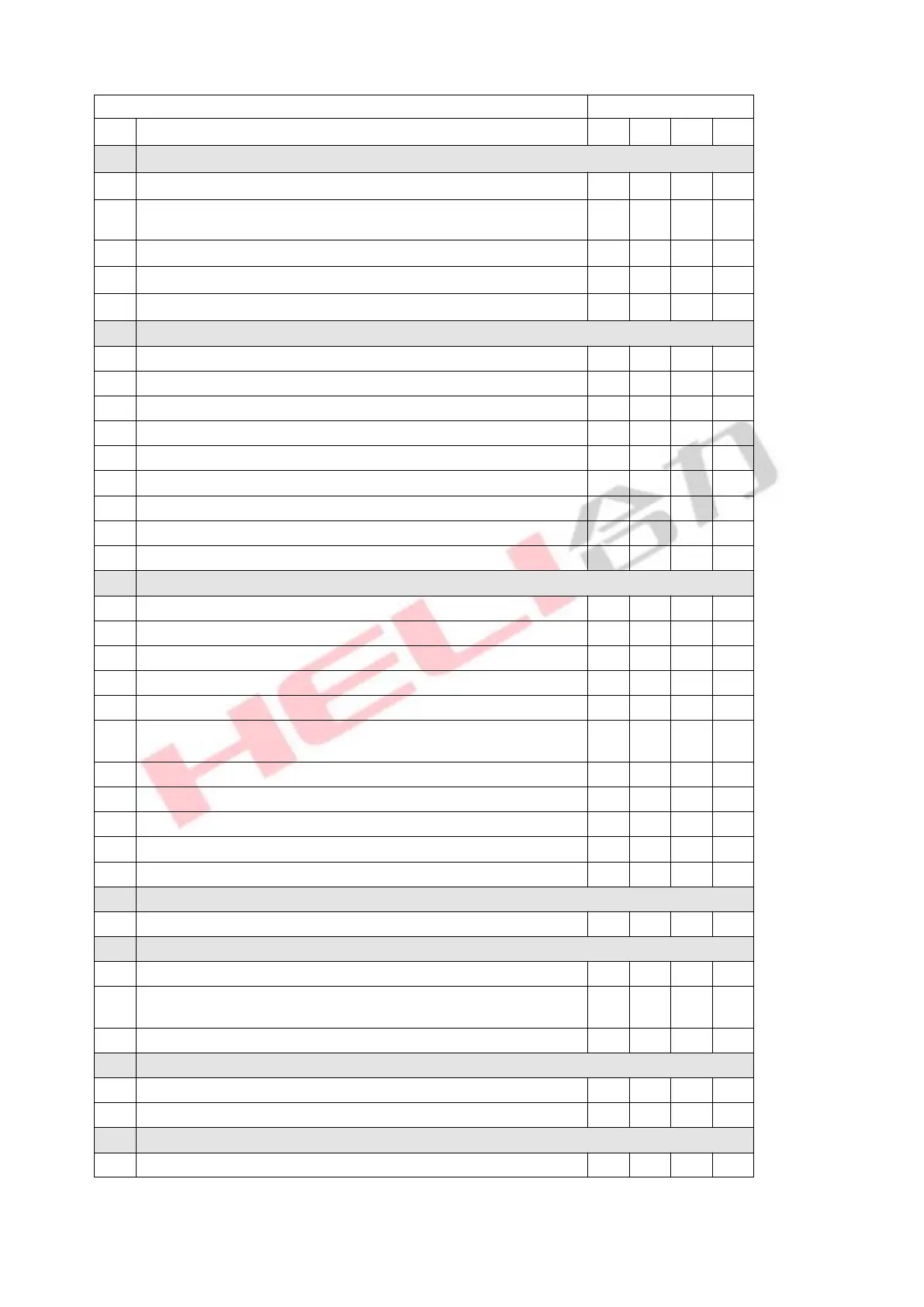

16

5.3.1 Maintenance checklist

Check the hydraulic cylinder, piston for damage noise or leakage

Inspect hydraulic connectors and hose for damage and

leakage

Check the hydraulic level and refill if necessary

Refill with hydraulic oil (12 months or 1500 working hours)

Check and adjust pressure valve function (+10%)

Check the platform structure for deformation and cracks

Check the base for deformation and cracks

Check that all screws are fixed

Check gear box for noise and leakage

Inspect wheels for deformation and damage

Lubricated steering bearing

Check and lubricate central point

Lubricating grease nozzle

Replace the protection and/or protection plate if damaged

Check the wires for damage

Check electrical connections and terminals

Check the emergency stop switch function

Check electric drive motor for noise and damage

Check that the correct fuse is used and replace it if

necessary

Check the current contactor

Check frame for leakage (insulation test)

Check the function and wear of accelerator

Check the electrical system of the driving motor

Check braking performance, replace brake disc or adjust

Clean and grease terminal, check for corrosion and

damage

Check the battery shell for damage

Check the main power wires for damage

Check the startup protection during charging

Loading...

Loading...