Preventive Maintenance 24 17730-241

AR2

™

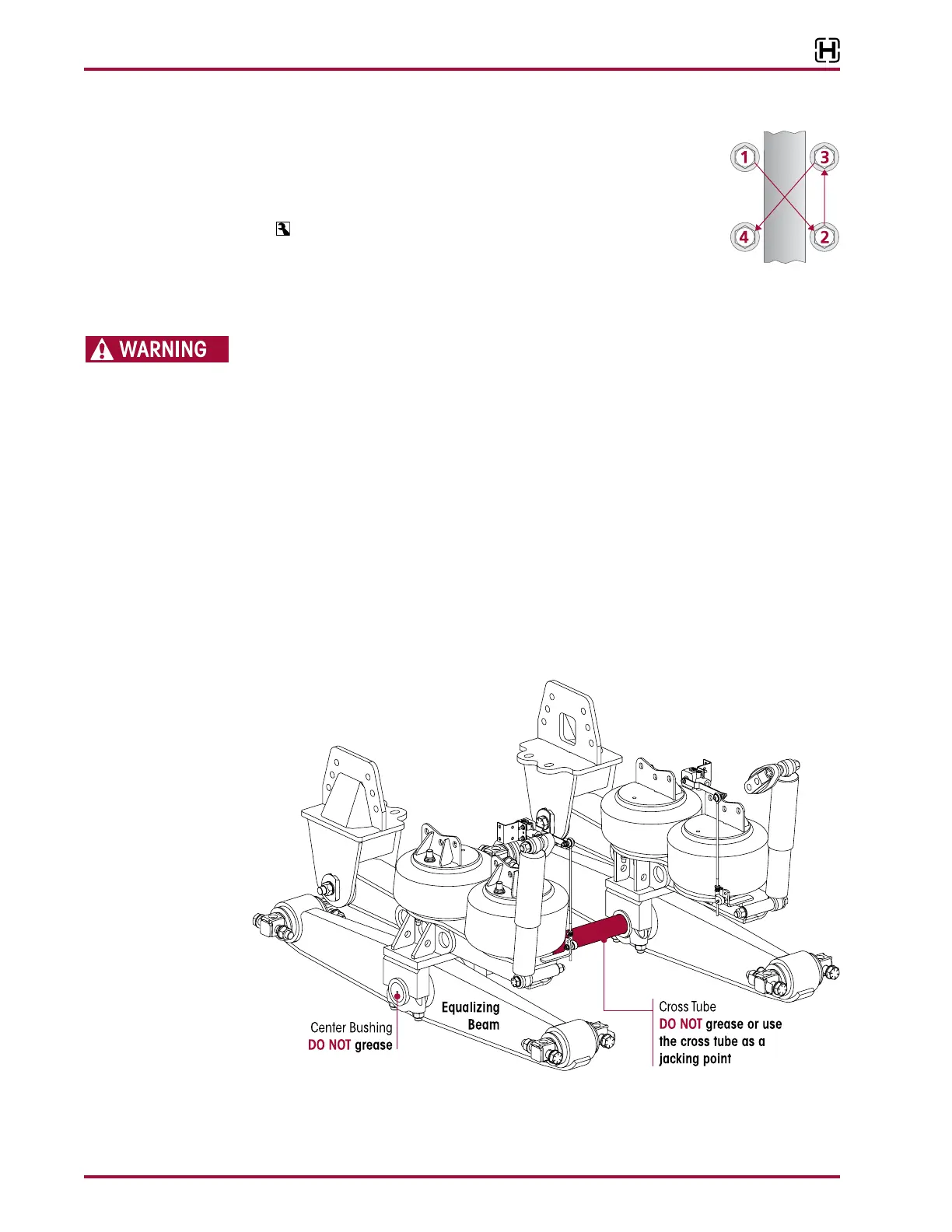

1. While tightening the saddle cap stud fasteners maintain an even gap

between the saddle assembly base and the saddle cap, see Figure 6-14.

2. Center the saddle on the equalizing beam center bushing.

3. Tighten the saddle cap fasteners evenly in 50 foot pounds increments to

250 ± 25 foot pounds torque in the proper sequence to achieve uni-

form bolt tension as shown in Figure 6-14 until the final torque value is

achieved. exceed specified torque on saddle cap fasteners.

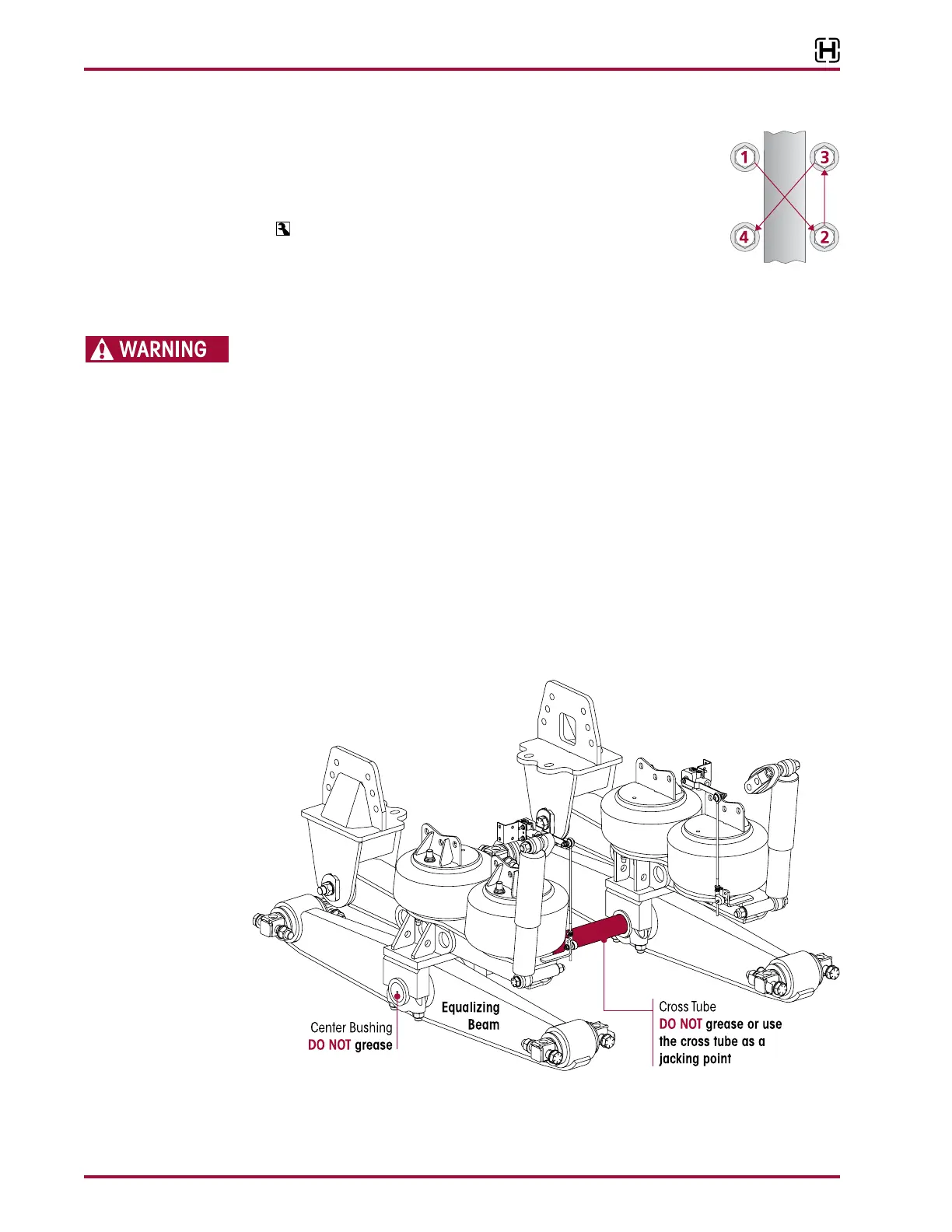

IMPROPER JACKING METHODS CAN CAUSE STRUCTURAL DAMAGE WHICH CAN CAUSE ADVERSE

VEHICLE HANDLING, PROPERTY DAMAGE OR SEVERE PERSONAL INJURY AND WILL VOID

HENDRICKSON’S WARRANTY.

■

DO NOT USE THE SUSPENSION CROSS TUBE, BAR PIN AXLE BRACKETS AS A JACKING POINT, SEE

FIGURE 6-15, REFER TO VEHICLE MANUFACTURER FOR PROPER JACKING INSTRUCTIONS

■

ACCEPTABLE LIFTING POINTS FOR A VEHICLE AT THE RATED LOAD INCLUDE BUT NOT LIMITED

TO: THE AXLE, EQUALIZING BEAM, AND THE VEHICLE FRAME RAIL. REFER TO THE VEHICLE

MANUFACTURER FOR PROPER JACKING INSTRUCTIONS

The AR2 cross tube connects the two (2) equalizing beams through the equalizing

beam’s center bushings, see Figure 6-15. The cross tube has clearance to float side-to-side in the

center bushings.

The length of the cross tube will allow side-to-side movement of approximately 1.9685" (50mm).

For this reason, the cross tube may appear polished or have missing paint at each end where it

enters into the center bushings, this is normal.

grease or lubricate the cross tube or the center bushing and use the cross tube

as a jacking point, see Figure 6-15.

Loading...

Loading...