Component Replacement 60 17730-241

AR2

™

■

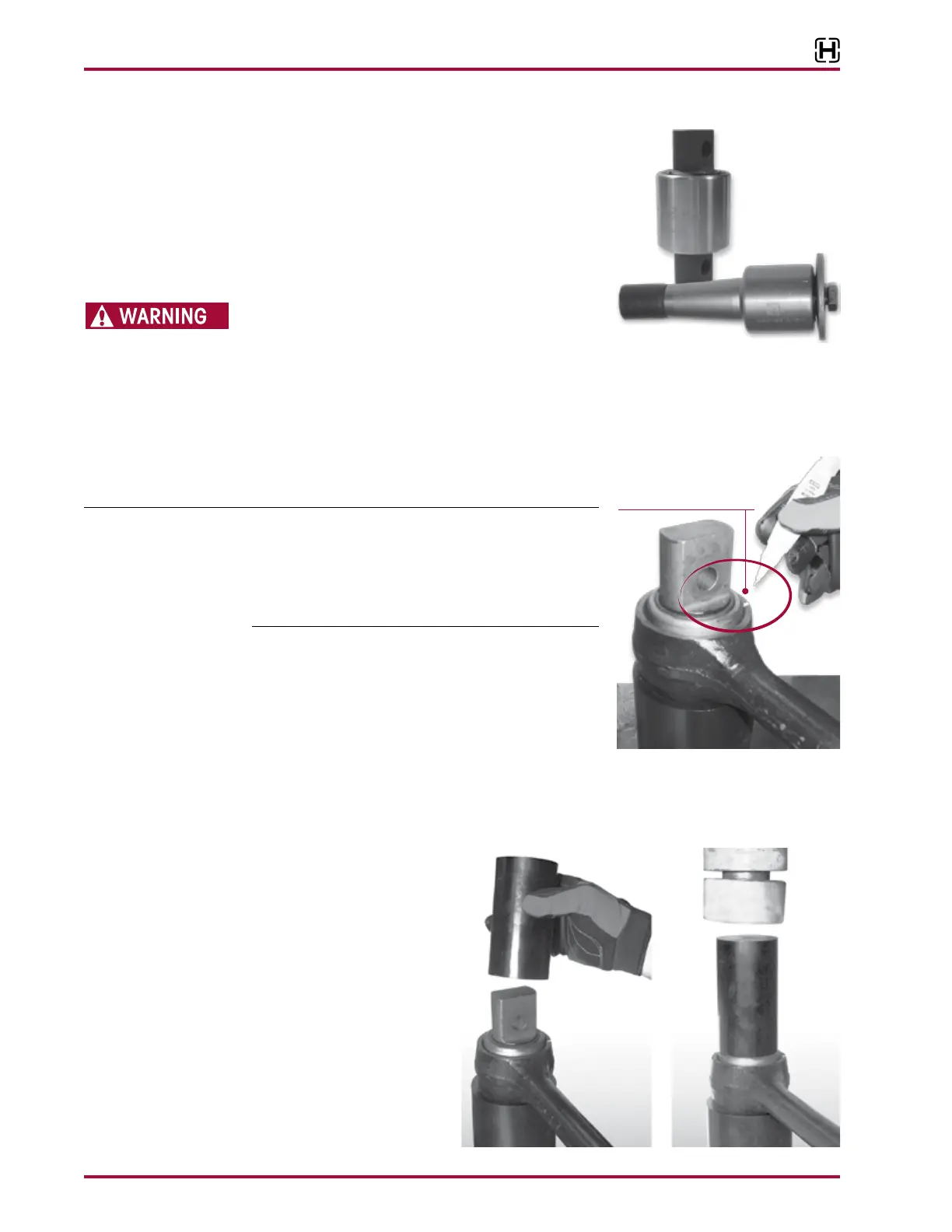

A vertical press with a capacity of at least 10 tons

■

Shop made receiving tool and installation / removal

tool, see the Special Tools section of this publication

for more information

DO NOT USE HEAT OR USE A CUTTING TORCH TO REMOVE

THE BUSHINGS FROM THE TORQUE ROD. THE USE OF HEAT

WILL ADVERSELY AFFECT THE STRENGTH OF THE TORQUE

ROD, HEAT CAN CHANGE THE MATERIAL PROPERTIES. A COMPONENT DAMAGED IN THIS MANNER CAN

RESULT IN ADVERSE VEHICLE HANDLING AND POSSIBLE PERSONAL INJURY OR PROPERTY DAMAGE.

1. Remove the torque rod(s) as detailed in Torque Rod

Disassembly instructions in this section.

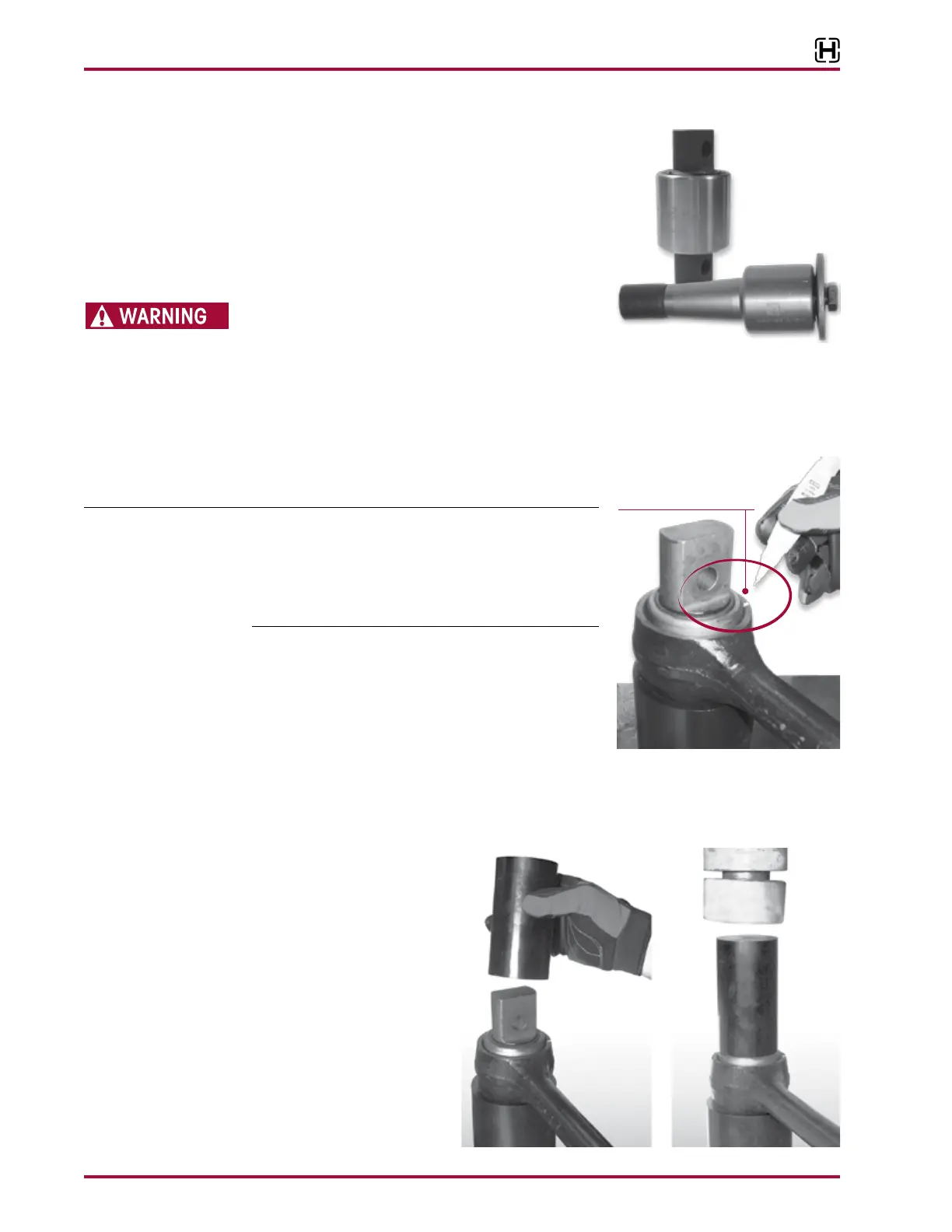

When servicing a straddle mount bar pin bushing assem-

bly, mark the clocking position of the straddle mount bar

pin flats with a paint stick on the torque rod end hub prior

to disassembly, see Figure 8-42. This marking will serve as

a guide when installing the new bushing assembly so the

original clocking position can be retained.

2. Mark the clocking position of the straddle mount bar

pin flats with a paint stick on the torque rod end hub

prior to disassembly, see Figure 8-42.

3. Support the torque rod end hub centered on the receiv-

ing tool. Be sure the torque rod is squarely supported on

the press bed for safe ty.

4. Push directly on the straddle mount bar pin, until the top of the bar pin is level with the top of

torque rod end hub, see Figure8-43.

5. Place the shop made

removal tool on the bar pin

and press until the bushing

clears the torque rod hub,

see Figure 8-44.

6. Remove the fastener from

the tapered bar pin bush-

ing, and support the torque

rod hub on the receiving

tool with the tapered stud

pointing down and the end

hub centered on the tool.

Be sure the torque rod is

squarely supported on the

press bed for safety.

Mark the clocking position of the

bar pin ats with a paint stick

on the torque rod end hub

Loading...

Loading...