Component Replacement 56 17730-241

AR2

™

14. Install the saddle caps, refer to Saddle Cap Assembly in this section.

15. Install the tires.

16. Remove the supports from the drive axles and lower the vehicle onto the ground.

17. Remove the wheel chocks.

AR2 SUSPENSIONS INCORPORATE TORQUE RODS FOR VEHICLE STABILITY. IF THESE COMPONENTS

ARE DISCONNECTED OR ARE NON-FUNCTIONAL, THE VEHICLE SHOULD NOT BE OPERATED. FAILURE

TO DO SO CAN RESULT IN ADVERSE VEHICLE HANDLING, ADVERSE VEHICLE HANDLING, POSSIBLE TIRE

CONTACT WITH THE FRAME, PREMATURE COMPONENT DAMAGE, OR SEVERE PERSONAL INJURY.

1. Chock the front wheels

of the vehicle.

2. Support the pinion on

the axle being serviced.

To remove all the load from

the longitudinal torque rods,

raise or lower the pinion as

needed. This will ease the

removal of the longitudinal

torque rod.

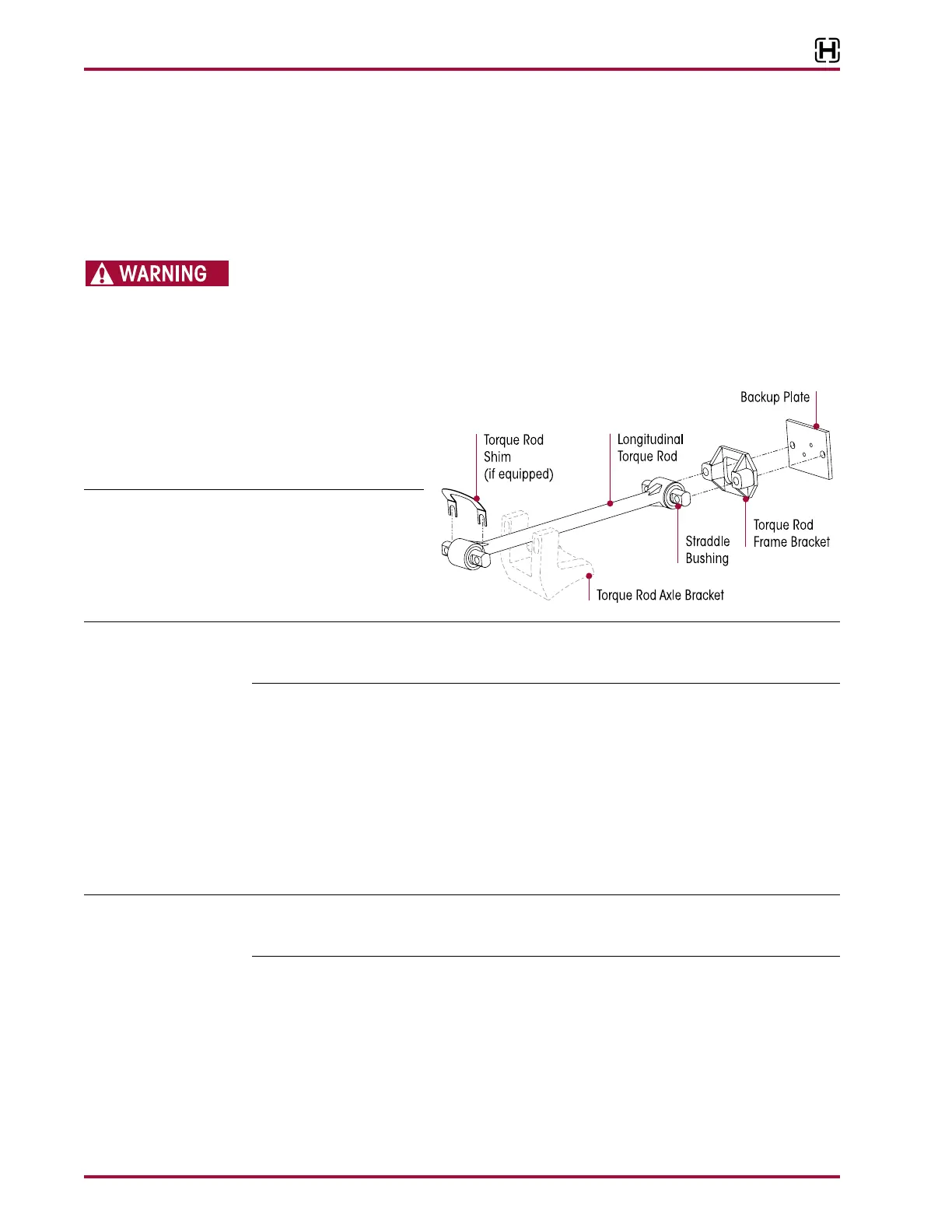

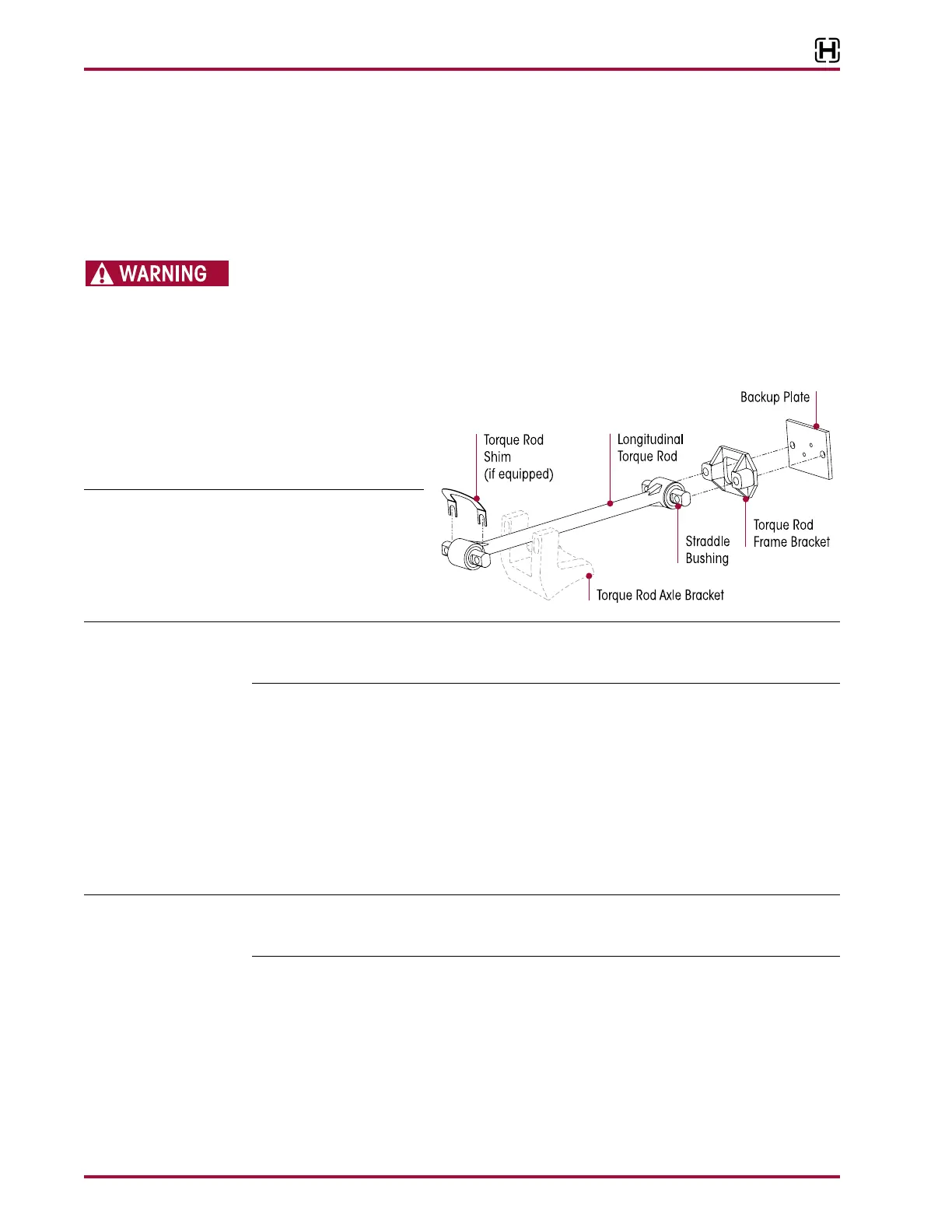

Prior to disassembly of the longitudinal torque rods, note the quantity and orientation of the lon-

gitudinal torque rod shims. It is required that the longitudinal torque rod shims are installed in the

same orientation and location as removed to preserve the existing alignment.

3. Remove the torque rod mounting fasteners and shims (if equipped).

4. Remove the fasteners that connect the longitudinal torque rod to the cross member and

axle brackets.

5. Remove longitudinal torque rods, see Figure 8-34.

1. Install longitudinal torque rods.

2. Install new fasteners and any shims (that were equipped) to the cross member and torque

rod axle brackets.

Hendrickson recommends the use of grade 8 bolts and grade C locknuts. If flange head bolts

and locknuts are not used then hardened structural washers must be used under bolt heads

and locknuts.

3. Tighten all fasteners to vehicle manufacturer’s torque specifications.

4. Verify proper pinion angle, and correct with drop in shims between the torque rod bar pin

and the cross member or torque rod axle bracket depending on the direction of adjustment

needed. Contact the vehicle manufacturer for proper pinion angle specifications.

5. Remove wheel chocks.

Loading...

Loading...