Preventive Maintenance 18 17730-241

AR2

™

An inspection of the beam end connections are necessary when a vehicle is in the shop for major

repair work or every six months, whichever comes first. Periodic visual inspection by the driver and

service personnel is also recommended. Off-highway and severe service operating conditions

require more frequent inspections than on-highway service operation.

The equalizing beam end connection requires that the fasteners are tightened to torque specifi-

cations to maintain the clamp load of the axle bracket legs to the bar pin. All bushing motion is

accommodated by rubber deflection.

■

1. Chock the wheels.

2. Visually inspect suspension components for signs of movement or excessive wear.

■

Inspect alignment shims in equalizing beam end for looseness. Lightly tap on the align-

ment shims to see if they can be moved. If movement is detected, tighten fasteners to the

proper torque value, see Figure 6-6

■

Inspect equalizing beam end connection for signs of excessive wear or looseness

An equalizing beam end connection, which is visibly cleaner than the other connections, may

indicate a loose connection.

■

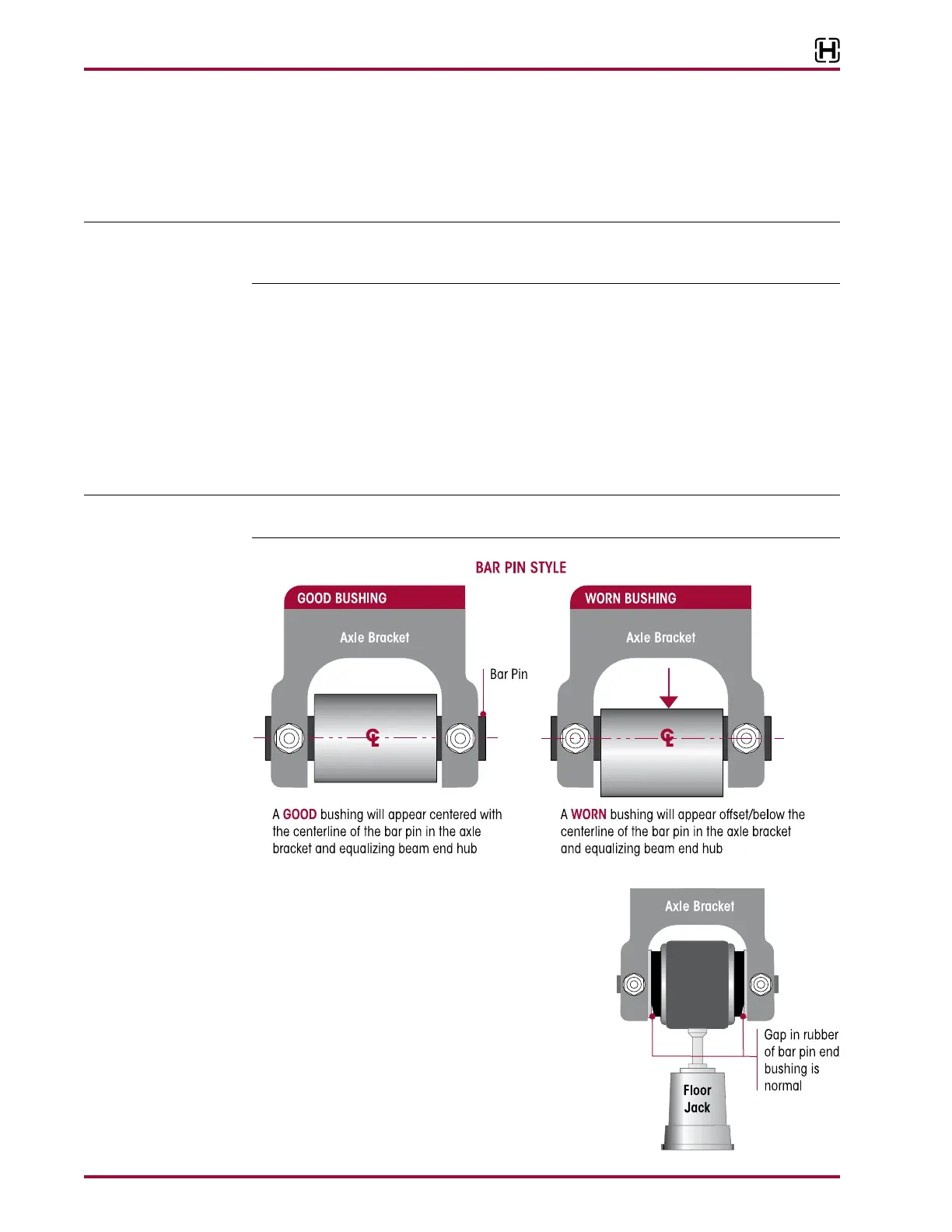

Look for worn, frayed or distorted rubber in the bar

pin beam end bushing, see Figure 6-4

■

Look for the equalizing beam to be lower in the

beam hanger, see Figure 6-4

■

If the bar pin beam end bushing is visually offset

a floor jack test should be performed. See Jack

Test in this section

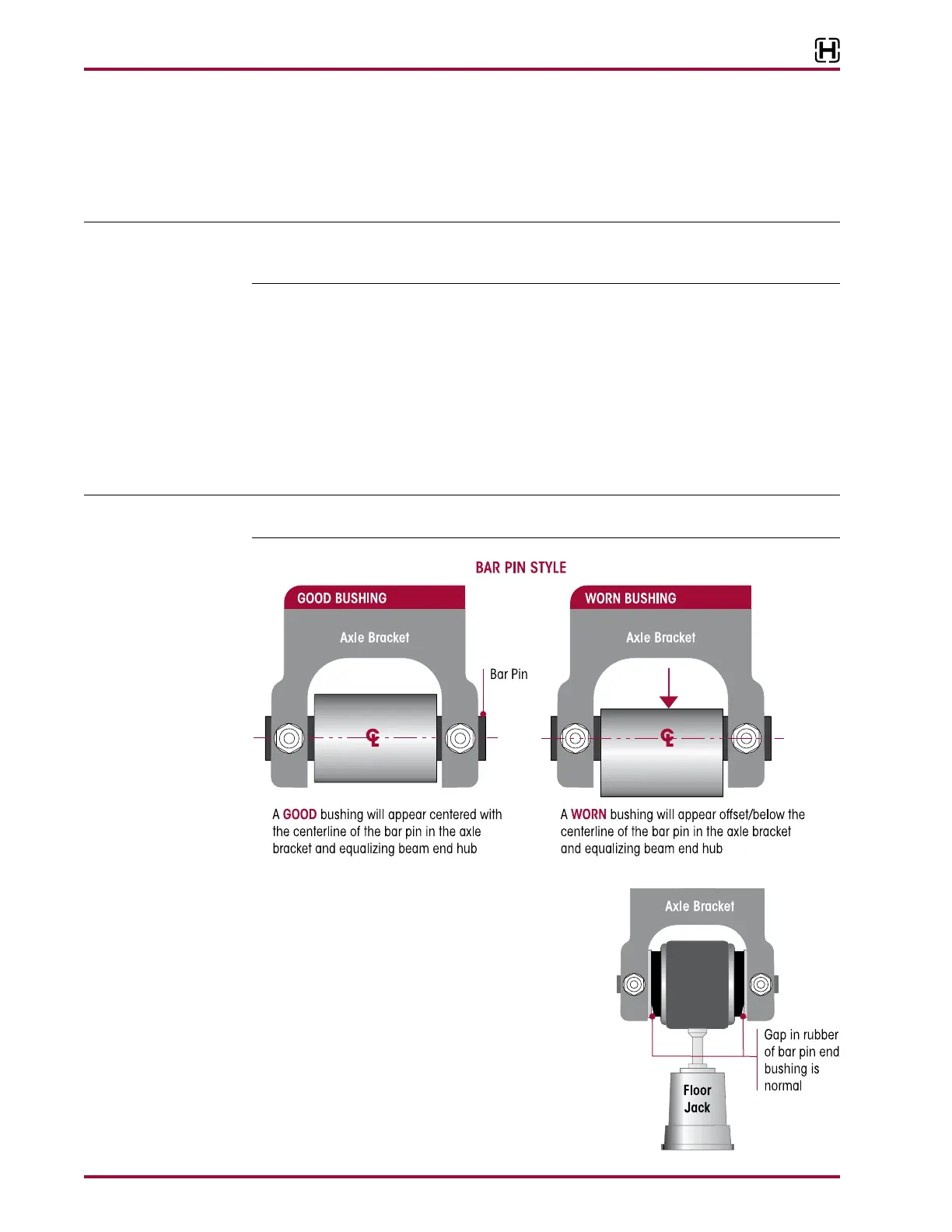

1. Place a jack under each beam end as shown. Raise

the jack to check for movement in the connection or

rubber components, see Figure 6-5.

Loading...

Loading...