17730-241 55 Component Replacement

AR2

™

CHECK TO ENSURE PROPER ALIGNMENT OF TOOLING

ADAPTERS WITH EQUALIZING BEAM COMPONENTS

BEFORE APPLYING FULL HYDRAULIC PRESSURE WITH

A SHOP PRESS.

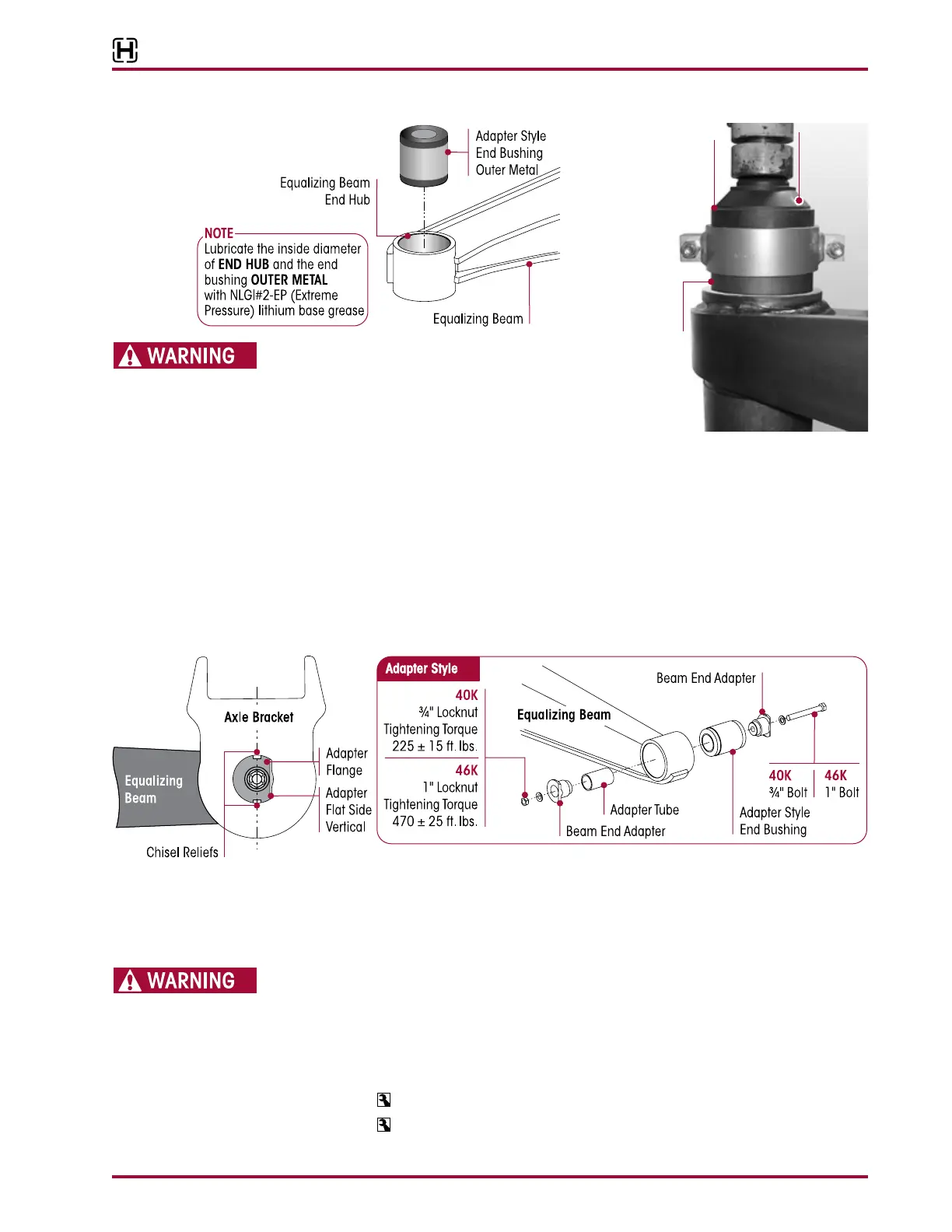

5. Apply hydraulic force and press the new bush-

ing into place. The bushing will be completely seated when the clamp makes contact with the

beam face.

6. Using the floor jacks, slowly raise both equalizing beams and cross tube as an assembly

into the axle brackets. Ensure that each equalizing beam end bushing correctly engages

the axle bracket.

7. Install one (1) adapter through the axle bracket leg at the wheel side, into the beam

end bushing.

8. Install the other adapter through the axle bracket leg at the axle side, taking advantage of the cut-

off flange on the adapter to clear the axle.

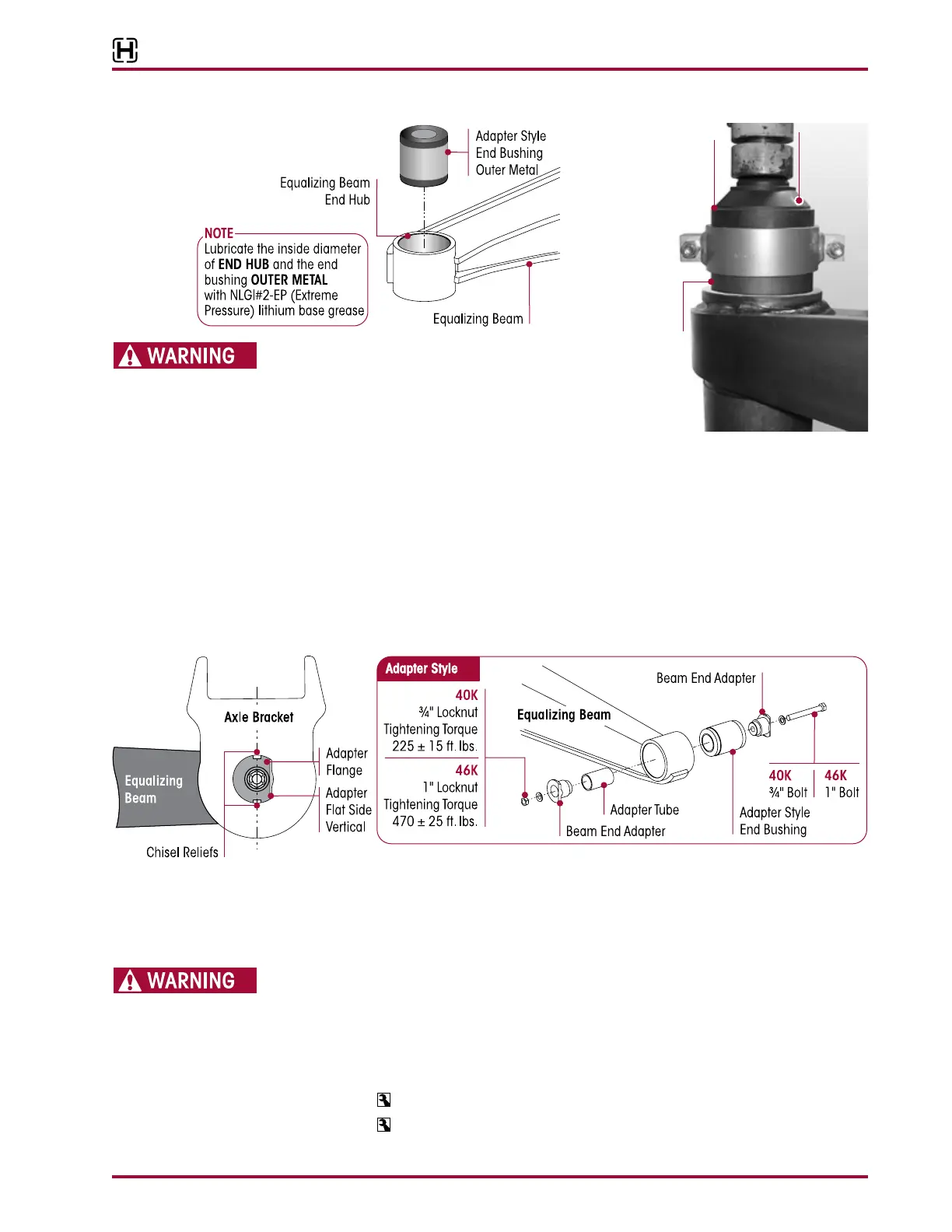

9. Rotate the adapters so that the adapter cut-off flats are vertical as shown in Figure 8-32.

10. Install the end shaft and slotted nuts.

11. Place the axles in their normal operating positions before the slotted nuts are torqued to

specifications.

IF THE TIGHTENING TORQUES RECOMMENDED BELOW ARE NOT PROPERLY MAINTAINED, THE METAL

SURFACES OF THE AXLE BRACKET LEGS, HOLES, ADAPTERS AND RUBBER BUSHING INNER METALS CAN

EXPERIENCE EXCESSIVE WEAR AND / OR FAILURE. THIS CAN CAUSE SEPARATION OF COMPONENTS

AND ADVERSE VEHICLE HANDLING, PROPERTY DAMAGE OR PERSONAL INJURY.

12. Tighten the locknuts until final torque value is achieved, specified

torque value.

■

40K — 225 ± 15 foot pounds torque

■

46K — 470 ± 25 foot pounds torque

13. Remove the frame supports and lower the saddle onto the center bushings.

Adapter

Tool

Clamp

Equalizing Beam

Adapter Style

Rubber End

Bushing

Tapered

End Up

Loading...

Loading...