Component Replacement 54 17730-241

AR2

™

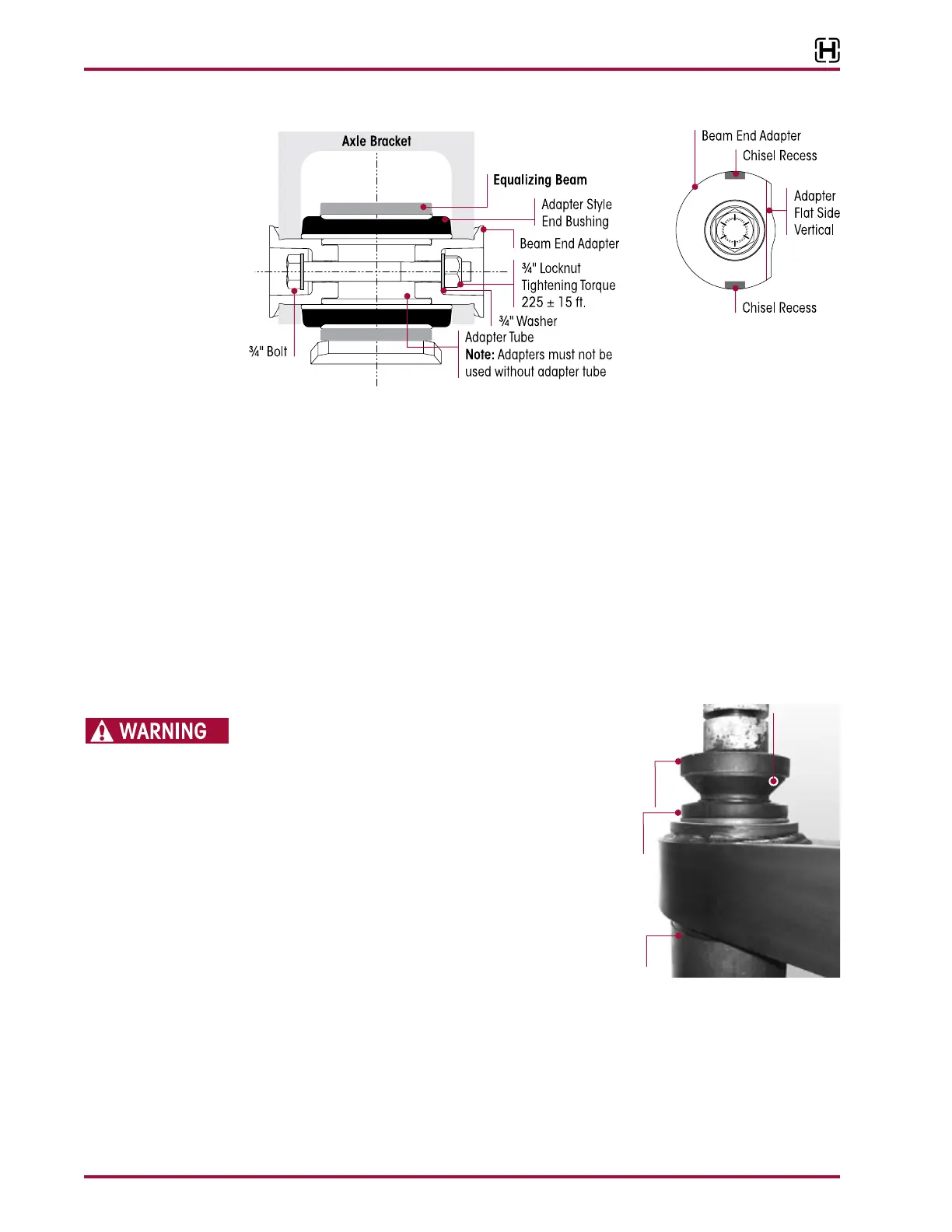

10. The beam end adapters have two chisel recesses located in their flanges as shown in

Figure 8-28.

11. Locate the recess for the chisel, rotate the adapter if necessary. Place the air hammer / chisel

in the recess to rotate the adapter collar.

12. If the beam end adapter does not turn, use a hammer to rap the outside of the axle bracket

legs around the adapter area and repeat air hammer chisel procedure until removed.

13. Remove the beam end adapter from the other equalizing beam ends.

14. Slowly lower the floor jacks and remove / pry the equalizing beams from the axle brackets.

15. Remove the end bushing adapter tube (if equipped), see Figure 8-27.

16. Remove the floor jacks from under the equalizing beams.

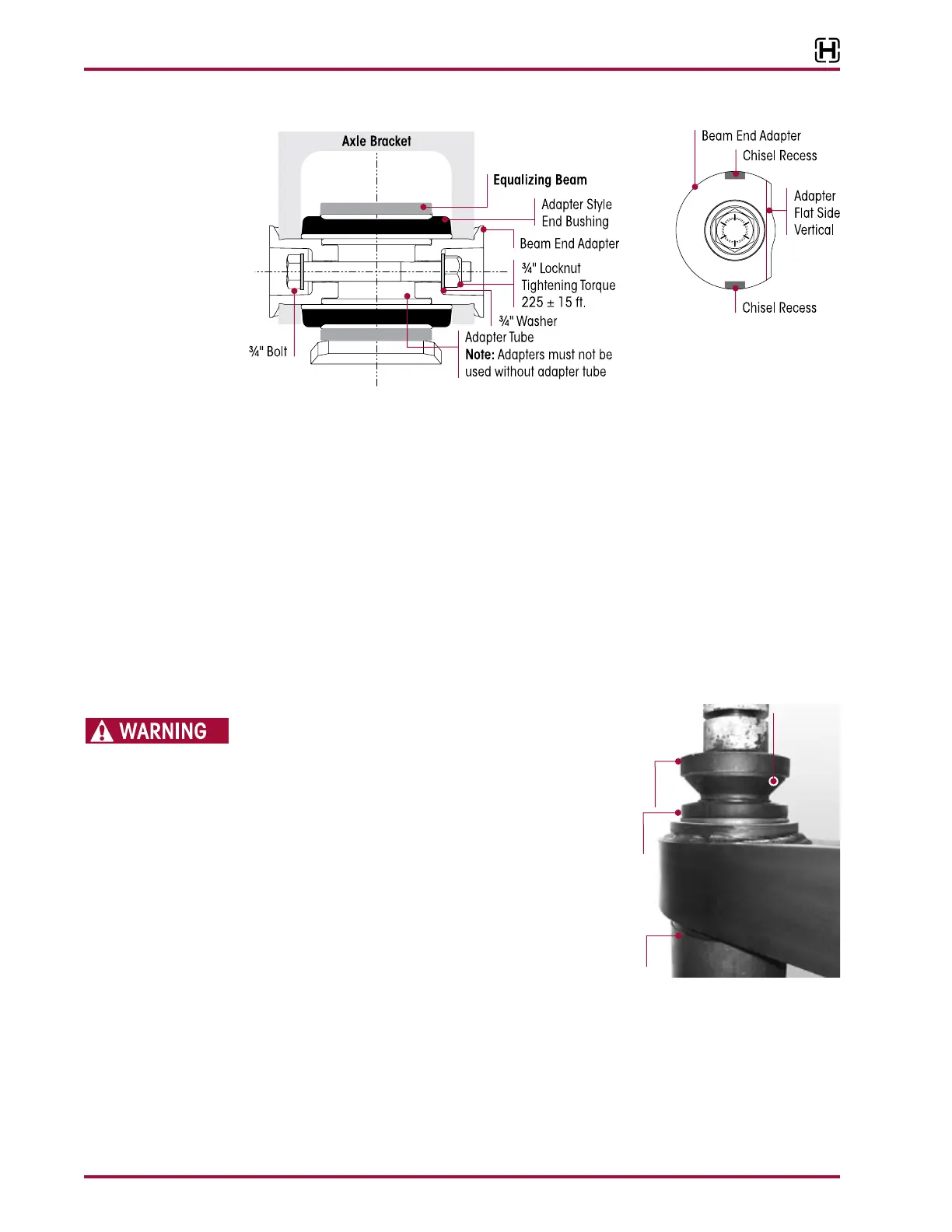

17. Position the equalizing beam in the shop press and align the end bushing removal /

replacement adapter tool with the tapered end down on top of the rubber end bushing,

see Figure 8-29.

CHECK TO ENSURE PROPER ALIGNMENT OF TOOLING

ADAPTERS WITH EQUALIZING BEAM COMPONENTS

BEFORE APPLYING FULL HYDRAULIC PRESSURE WITH

A SHOP PRESS.

18. Apply hydraulic force and remove the

old bushing.

19. Inspect the axle bracket legs per the Beam End

Axle Brackets, Physical Inspection for Adapter

Style bushings in the Preventive Maintenance

section of this publication.

1. Clean the equalizing beam bushing bore with a

cylinder ball hone or emery paper of any debris.

2. Lubricate the equalizing beam bore and the equalizing beam center bushing outer metal

sleeve with an NLGI#2 – EP (Extreme Pressure) grease, see Figure 8-30.

3. Position the end bushing removal / replacement adapter with the tapered end up onto the

clamp, see Figure 8-31.

4. Use a wrench to tighten the installing clamp tool on the rubber bushing and the end bushing

replacement adapter as shown in Figure8-31.

End Bushing

Adapter

Receiver

Equalizing Beam

End

Bushing

Tapered

End Down

Loading...

Loading...