Component Replacement 46 17730-241

AR2

™

A BAR PIN SHIM MUST BE INSTALLED AT EACH BOLT LOCATION. THE SAME PART NUMBER SHIM IN THE

SAME ORIENTATION MUST BE USED AT BOTH BOLT LOCATIONS ON ANY ONE (1) END BUSHING. DO NOT

INSTALL OR STACK MORE THAN ONE (1) SHIM AT EACH BOLT LOCATION. USE GENUINE HENDRICKSON BAR

PIN SHIMS, DO NOT USE STANDARD WASHERS. FAILURE TO FOLLOW THESE WARNINGS MAY RESULT IN

IMPROPER VEHICLE ALIGNMENT, FRACTURE OF THE AXLE BRACKET OR BAR PIN WHICH COULD RESULT IN

THE ADVERSE VEHICLE HANDLING AND POSSIBLE PERSONAL INJURY OR PROPERTY DAMAGE.

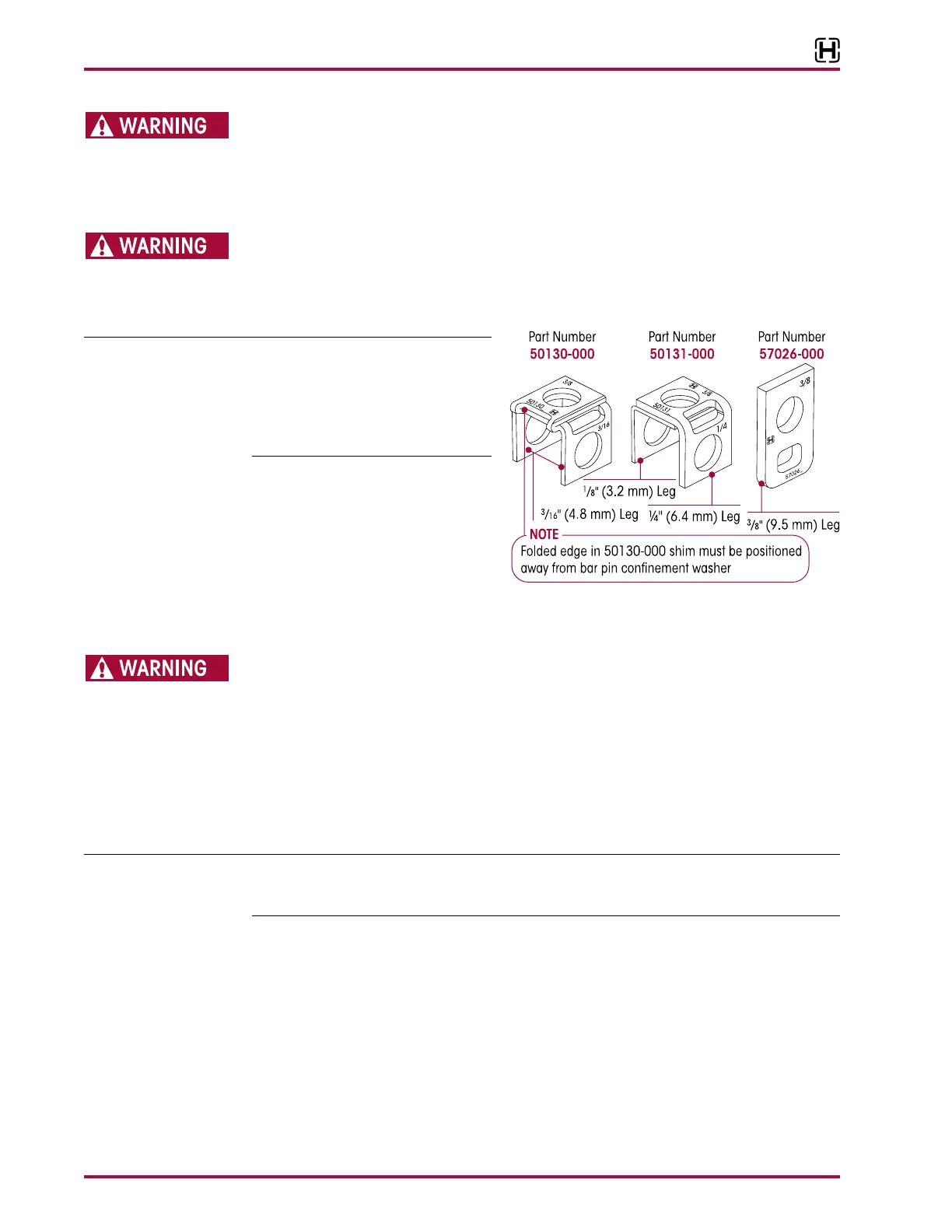

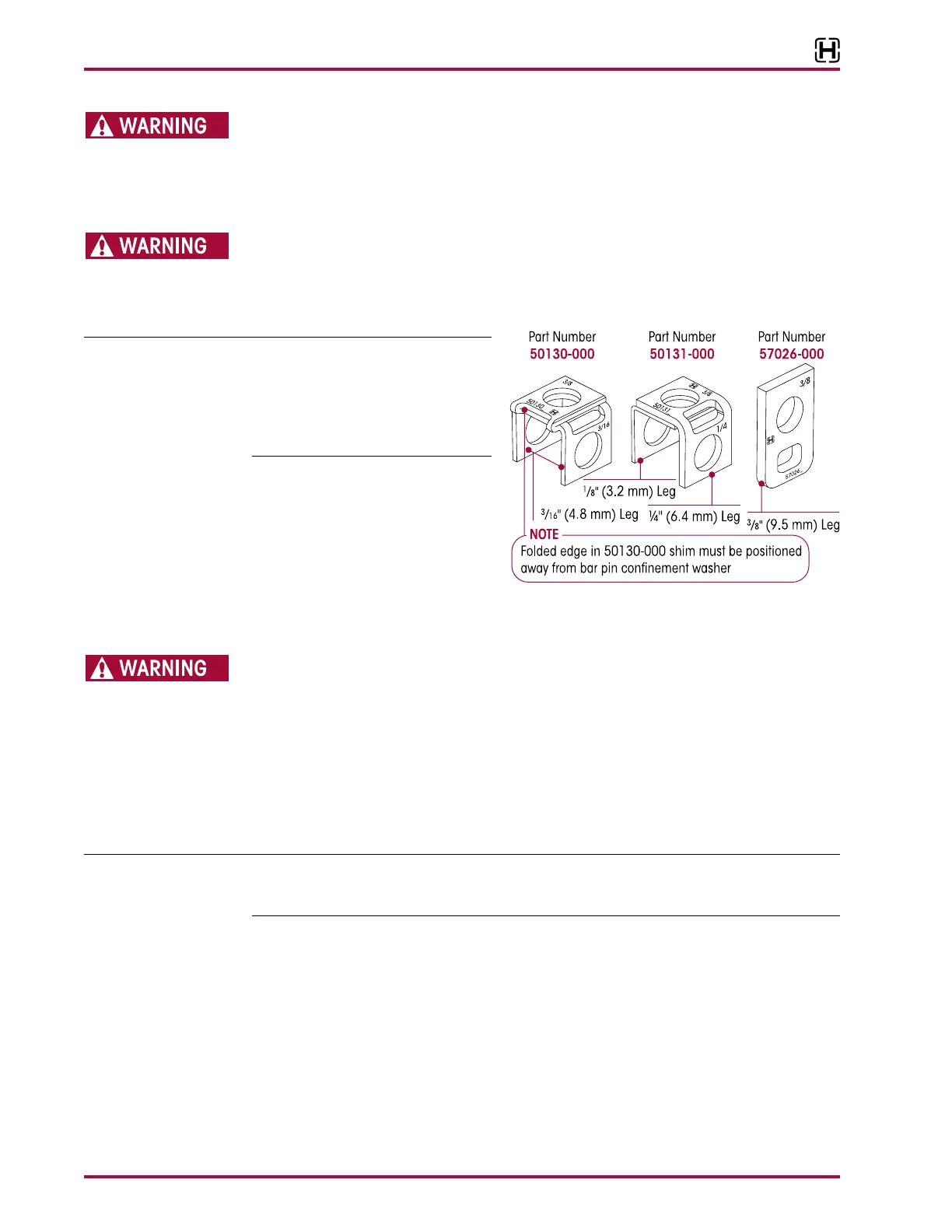

THE BAR PIN ALIGNMENT SHIM (PART NO. 50130-000) MUST BE INSTALLED WITH THE FOLDED EDGE

FACING AWAY FROM THE BUSHING, SEE FIGURE 8-13. FAILURE TO DO SO MAY RESULT IN SHIM DAMAGE,

IMPROPER ALIGNMENT, DAMAGE OR FRACTURE OF THE AXLE BRACKET OR BAR PIN WHICH COULD RESULT

IN THE ADVERSE VEHICLE HANDLING AND POSSIBLE PERSONAL INJURY OR PROPERTY DAMAGE.

Hendrickson recommends the use of

Grade 8 bolts and Grade C locknuts. If

flange head bolts and locknuts are not

used then hardened structural wash-

ers must be used under bolt heads

and locknuts.

8. Partially install the

bar pin alignment shim and verify

that the shim is in the same orien-

tation as prior to disassembly, see

Figure 8-10.

9. To complete installation of the

alignment shim, remove the tem-

porary ¾" bolt from the inboard bar pin hole and complete installation of the inboard

alignment shim.

DISCARD USED FASTENERS. ALWAYS USE NEW FASTENERS TO COMPLETE A REPAIR. FAILURE TO DO SO

COULD RESULT IN FAILURE OF THE PART OR MATING PARTS, ADVERSE VEHICLE HANDLING, PERSONAL

INJURY, OR PROPERTY DAMAGE.

10. Install the new 1" inboard bar pin fasteners. tighten at this time.

11. Repeat Steps 8 through 10 for the alignment shim.

12. Chock the drive axle wheels to prevent movement while installing the rear bar pin into

the axle bracket.

13. Support the current axle position of the rear axle pinion with a jack to assist with the installa-

tion of the rear bar pin.

Prior to disassembly of the longitudinal torque rod, note the quantity and orientation of the longitu-

dinal torque rod shims. It is required that the longitudinal torque rod shims are installed in the same

orientation and location as removed to preserve the existing pinion angle.

14. Disconnect the longitudinal torque rod from the axle bracket, see vehicle manu-

facturer’s specifications.

15. Release the rear parking brakes, this will allow the rear axle to rotate without rotating the tires.

16. Lower the rear drive pinion until the rear drive axle bracket legs are parallel to the rear bar pin

flats, see Figure 8-12.

17. Mount the equalizing beam into the drive axle brackets. install the bar pin

alignment shims at this time.

18. Slide a ¾" bolt through all rear axle bracket and the bar pin holes to temporarily support

the beams.

Loading...

Loading...