Please note before

start-up:

1. The electric supply must be the same as

given on the machine nameplate.

2. This machine is double insulated and

need not be grounded (earthed).

3. Do not exert undue pressure on the ma-

chine. This will not increase its performance.

Just position the bit and guide it into the

hole.

Lubrication of chuck: The chuck is not in-

corporated in the lubricating system of

the machine. The drill bit connection end,

therefore, must be cleaned regularly and

sprayed sparingly with Hilti lubricant.

Start-up time at low temperatures: Shorten

it by jolting the drill bit once against the base

material during the start-up.

Servicing:

Electric tools comply with respective

safety regulations. Servicing must, there-

fore, be carried out only by qualified elec-

trical specialists. For your safety, only

use original Hilti repair parts.

Operating:

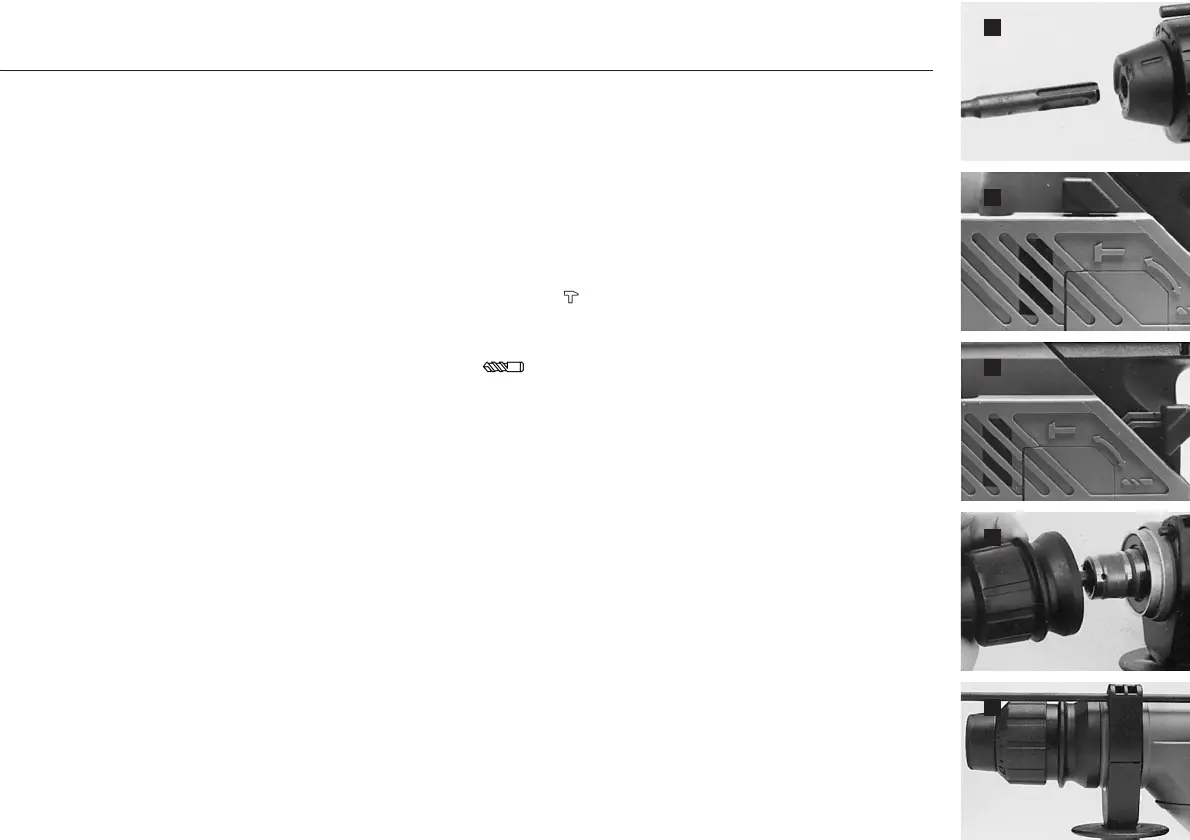

Fig. 1: Insertion of drill bit

Turn chuck to the left (symbol

()

). Insert

drill bit in any position until resistance is felt.

Then turn it until it moves in farther. Turn

chuck to right and lock drill bit in place (sym-

bol

()

).

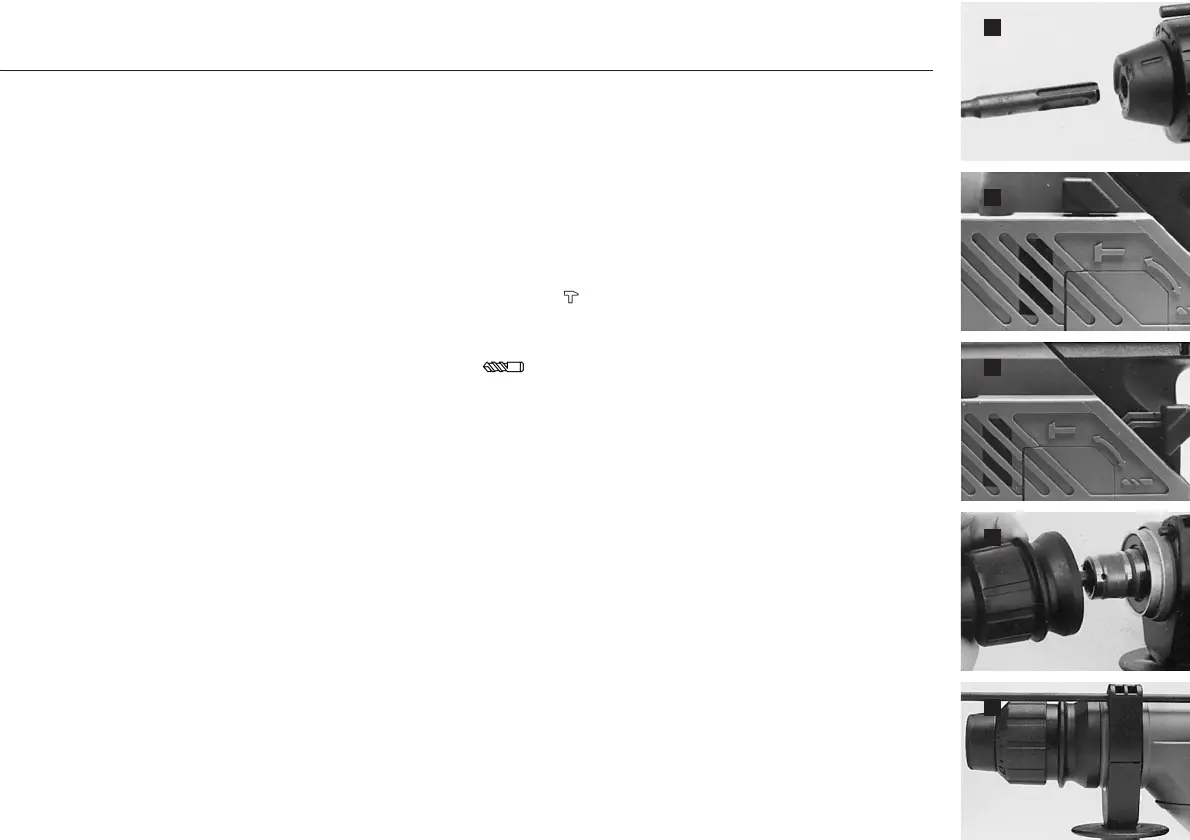

Fig. 2: Rotary hammer drilling

To hammer drill into concrete, masonry and

stone, shift setting lever to indicated rotary

hammer drilling position (symbol ).

Fig. 3: Rotary drilling

Shift setting sleeve to indicated rotary drilling

position (symbol ). Only the

rotary action is transmitted to the drill bit

in this position.

Fig. 4: Changing the chuck

Pull forward sleeve and completely remove

chuck. When attaching chuck pull for-

ward sleeve and hold it there. Press chuck

onto guide tube as far as it will go. Release

sleeve. Turn chuck until steel balls snap into

place.

Note:

On attaching a keyless chuck, the hammer-

ing action is automatically cut out i. e. rotary

drilling only is obtained.

Fig. 5: Side handle/depth gauge

Unscrew side handle to release depth gauge.

Adjust depth gauge and retighten.

Double insulation

The Hilti TE15 Hammer Drill is doublein-

sulated for extra operator protection. The

tool is equipped with a two-wire cord and

two-prong plug which can be used on stan-

dard 115 volts outlets. No grounding of the

tool is necessary.

1

2

3

4

5

Loading...

Loading...