5. Using a piece of insulation tape or a small soft

wedge lock the bias off switch in the ‘ON’

position.

6. Use the standard procedure test for electrical

safety. Do not exceed 1250 volt insulation test

duration of 3 seconds.

5. Record the test results.

6. Complete a functional (run) test and record

results.

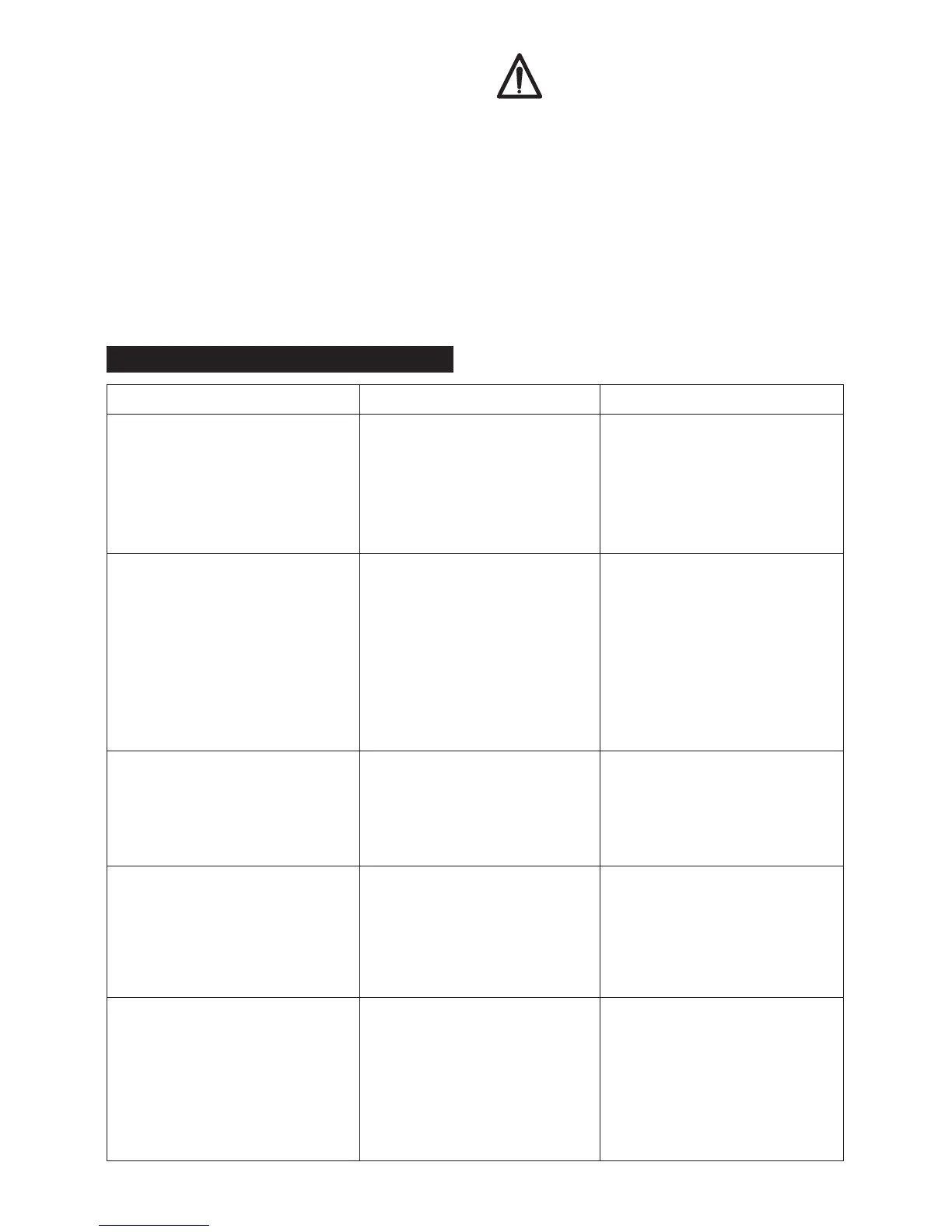

FAULT FINDING

FAULT CAUSE ACTION

The machine does not run. The power cable is not Connect the power cable to the

connected to the power supply. power supply.

The motor brushes are worn. Replace the motor brushes.

The voltage is too low. Check the main power

complies with the machine's

serial plate data.

The machine will not pickup The dust bag is full. Replace the paper dust bag or

dust. empty the cloth dust bag.

There is an obstruction in the Disconnect the machine from

dust pick-up. the power supply, tip the

machine back and remove the

sanding pad, check for

obstruction.

The dust brush is worn. Replace the dust brush.

The machine does not sand The sanding pad is damaged. Check and replace the sanding

evenly. pad.

The wheels are out of Check and adjust the wheels.

adjustment.

The sander does not glide easily The machine is not being Read the instructions, do not

in a straight line. operated properly. apply pressure when sanding.

The wheels are out of Check and adjust the wheels.

adjustment.

The Abrasive Pad Replace the Abrasive Pad

The machine runs slow. The voltage is low. Check the supply voltage.

If an extension lead is being

used, is it undersize and/or

is it coiled.

A motor brush is not making Check and refit or replace

contact. the motor brushes.

is worn.

CAUTION - when undertaking a

functional (run) test make sure the

machine is secure. Remember the

sanding pad will rotate.

9

Loading...

Loading...