1、CHECK

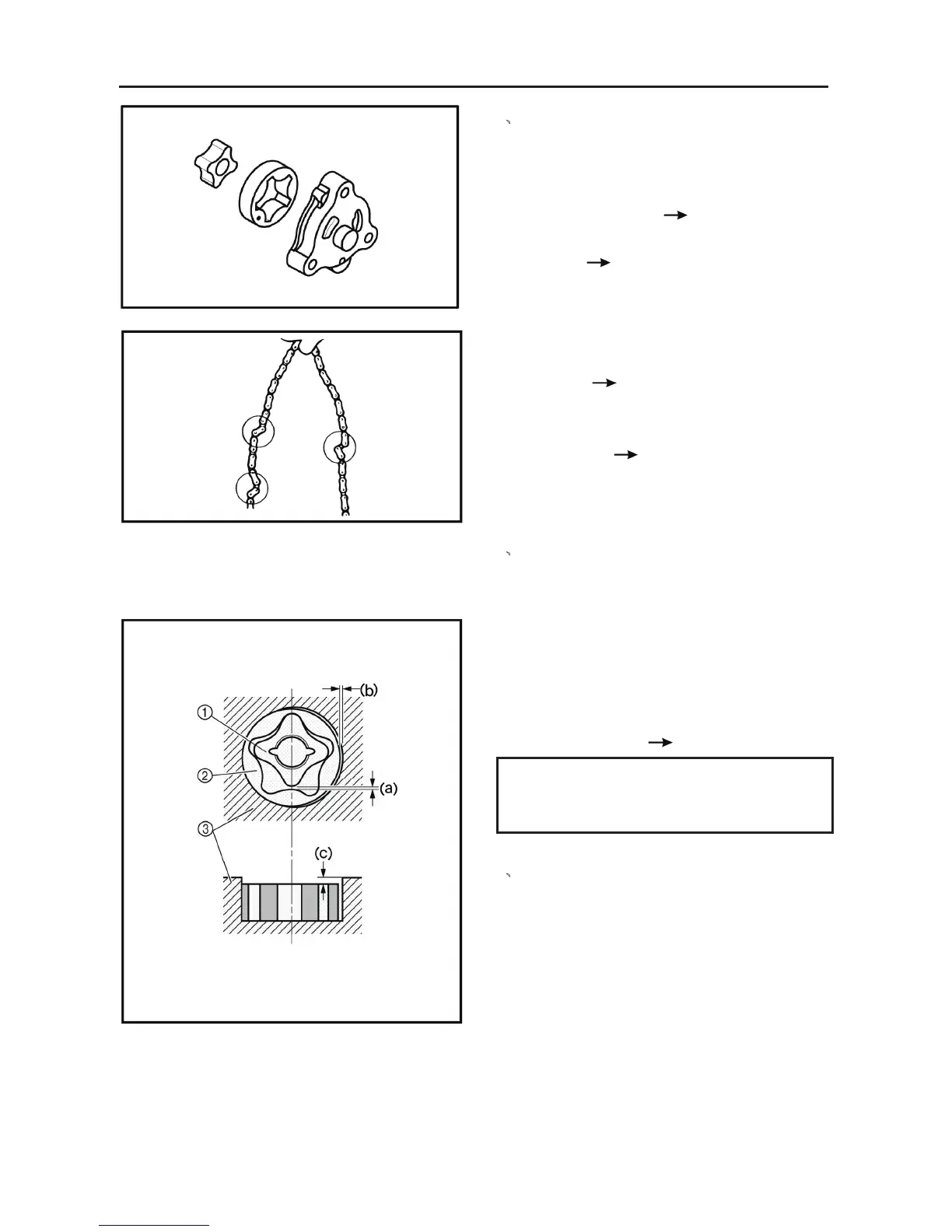

1). Checking the oil pump

• rotor housing

• rotor cover

Cracks/wear/damage

Replace.

• oil pump operation

Unsmooth

Repeat steps #1 and #2 or

replace the defective parts.

2) Checking the timing chain and guides

• timing chain

Cracks/stiff

Replace the timing chain and

camshaft sprocket as a set.

• timing chain guides

Wear/damage

Replace.

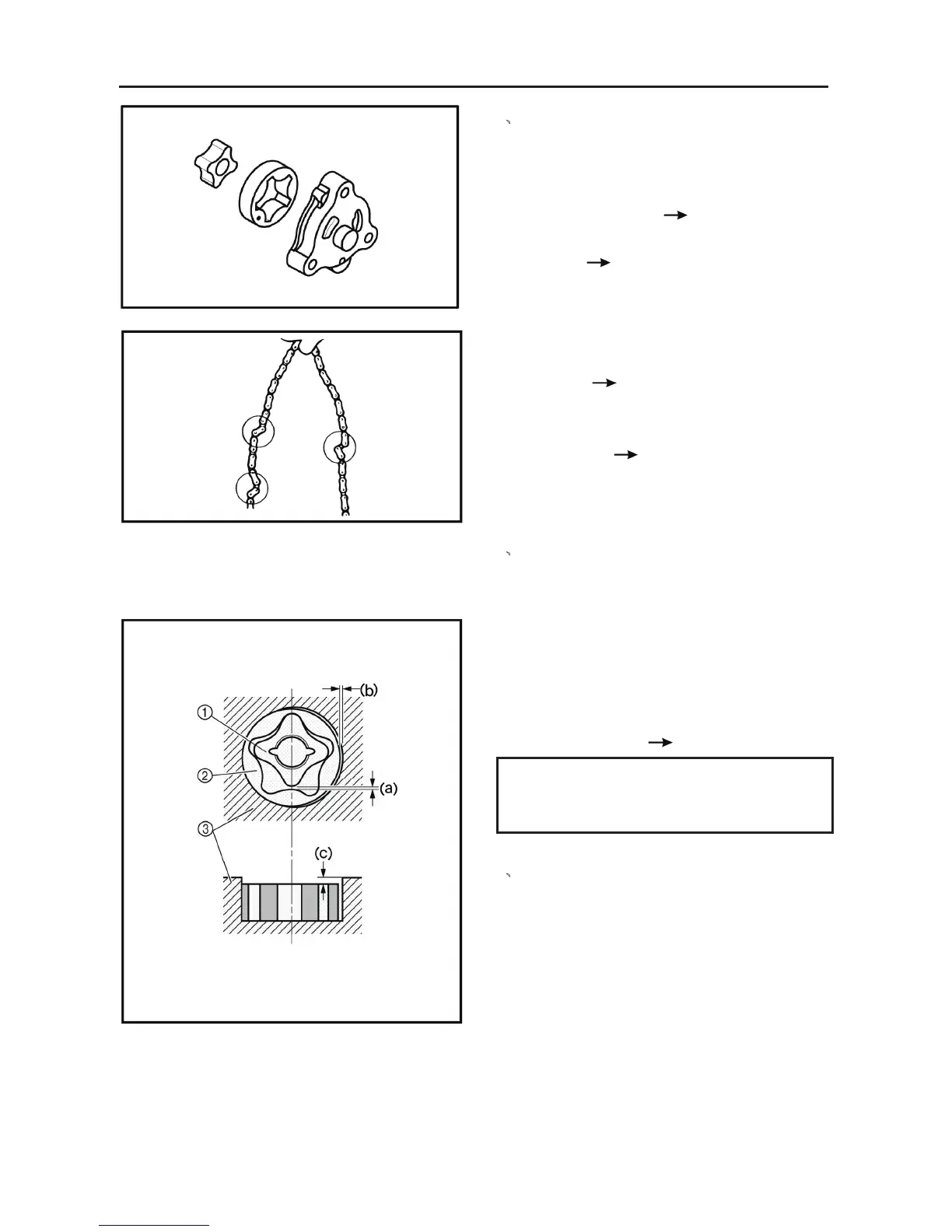

2、MEASURE

1). Measure the oil pump

• tip clearance(a) (between the

inner

rotor

①

and the out rotor ②)

• side clearance(b)(between the outer rotor ②

and the pump housing ③)

• body clearance (c) (between the outer rotor ②

and the pump housing ③)

Out of specification

Replace the oil pump.

Tip clearance Limit: 0.23 mm

Side clearance Limit: 0.25 mm

Body clearance Limit: 0.20 mm

3、INSTALL

1). Assembling the oil pump

• inner rotor

• outer rotor

• oil pump shaft (with the recommended

lubricant)

ENGINE

- 159 -

1、

MEASURE

1). Measure the crankshaft

• crank width (A)

Out of specification

Replace the crankshaft.

Crank width

54.95~ 55 mm(

2.1634~2.1654 in)

• side clearance (D)

Out of

specification

Replace the crankshaft

Big end side clearance Limit:

0.15 mm (0.0059 in)

• runout (b)(C)

Out of

specification

Replace the crankshaft.

Runout limit

(b): 0.03 mm (0.0012 in)

(C): 0.03 mm (0.0012 in)

The crankshaft ① and the crank pin ② oil

passages must be properly interconnected with

a tolerance of less than 1 mm (0.04 in).

.

CAUTION:

The buffer boss and woodruff key should be

replaced when removed from the crankshaft.

2). Assembling the crankcase

(1) Apply:

• sealant (Quick Gasket)

(to the mating surfaces of both case halves)

(2) Install:

• dowel pins

(3) Fit the left crankcase onto the right case. Tap

lightly on the case with a soft hammer

CAUTION:

Before installing and torque the crankcase

holding bolts, be sure to check whether the

transmission is functioning properly by

manually rotating the shift drum in both

directions.

Loading...

Loading...