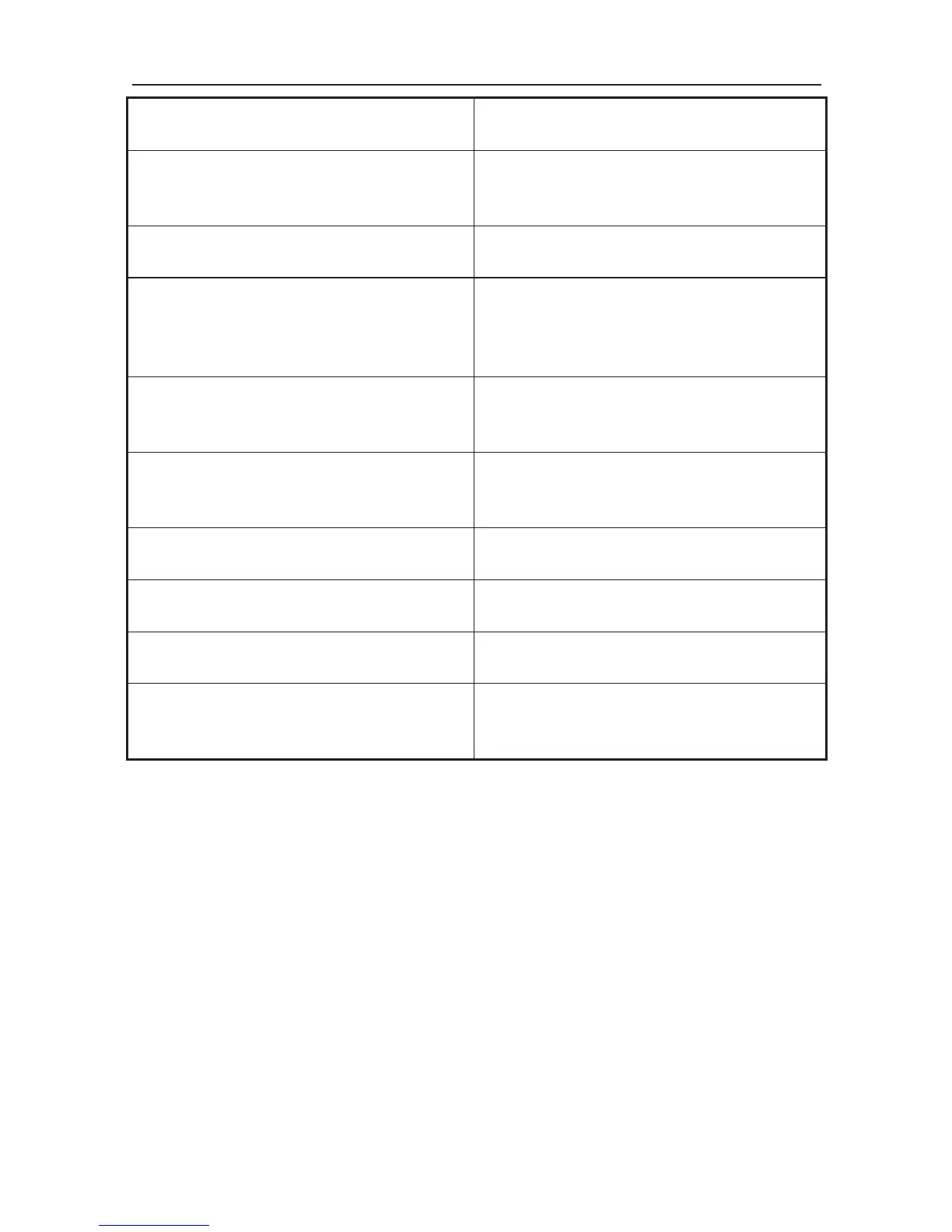

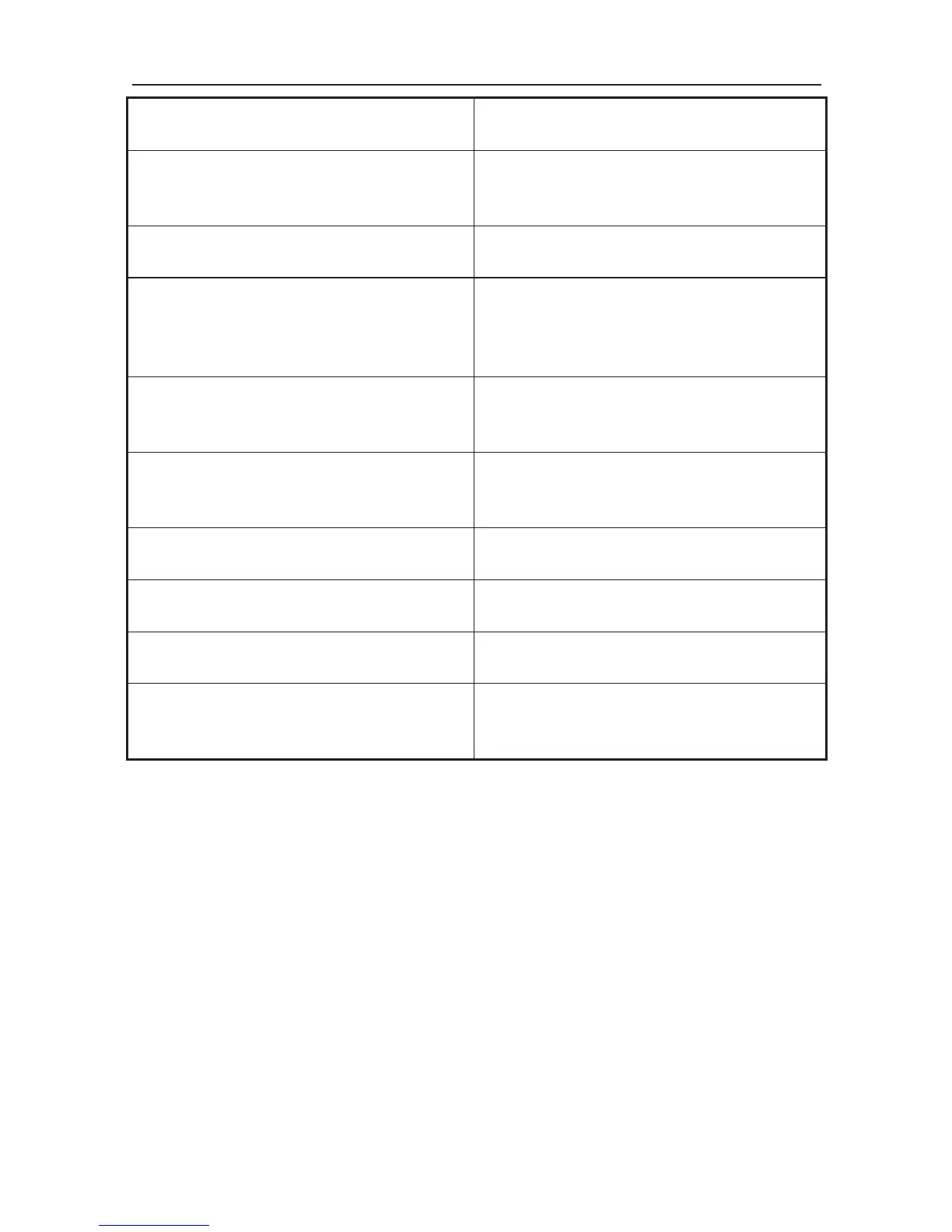

DO NOT: Tap on fuel injectors to correct any

malfunction.

Can damage injector.

DO NOT: Replace the injector with other

part number not recommended for this

application

Will severely affect the performance of the

injector

DO: Take extra care when installing new

fuel seal ring over injector inlet flange.

Prevent tearing seal ring during installation.

DO: Use proper lubricants on seal ring

surfaces to install injector in engine.

Minimize time between applying lubricant

and inserting injector / rail.

Avoid damage to seal ring during installation.

Avoid contamination at seal.

DO: Pulse (actuate) stuck closed or tip-leak

suspected injector (Actuate consists of one

pulse <5 sec duration at 9 to 15V).

To verify the injector failure

DO: Pulse (actuate) injectors prior to a dry

fuel system leak test at engine/vehicle

assembly to reseat injector valves.

Injector valves may not reseat without fuel

after shipping and handling resulting in false

leakage.

DO: Avoid any liquid contamination in the

injector area.

Coil could short circuit.

DO: Use care during connection of

harness to injector.

Avoid terminal damage.

DO: Use recommended terminal lubricant

on mating connector.

Minimize potential for terminal fretting

corrosion.

DO: Return any dropped, damaged, or

suspect material with a tag that describes

the problem.

Ensure fast and correct diagnosis of root

cause.

3. Installation guidelines

Follow these guidelines to prevent damage to the injector and its electrical interface during the

replacement or re-installation process.

Lubrication: Apply a light coating of lubricant to the lower injector seal ring. ISO 10 light

mineral oil or equivalent is recommended.

The preferred technique is to apply the lubricant to the sockets the injectors are being

installed into, rather than directly to the seal ring itself. This will help minimize the

possibility of injector contamination.

Avoid applying lubricant over the director plate holes – this may restrict injector flow. Do

not dip the injector tip in lubricant.

Multec 3.5 injectors come from the factory with the seal rings attached. The re-use of seal

rings is not preferred when replacing an injector. If an injector is to be re-used, and no new

seal rings are available, take care to inspect each seal ring for signs of damage. Even

minor defects in the seal ring can lead to leakage. Take extra care in installing seal ring

over flange of injector inlet.

ENGINE MANAGEMENT SYSTEM

- 267 -

Carefully installing the harness connector will prevent terminal damage. Listen for a

positive audible click from the connector retention device — this ensures that it is fully

engaged. Shut off ignition.

Disconnect negative battery cable to avoid possible fuel discharge if an accidental attempt

is made to start the engine.

Disconnect the electrical connector from the injector wiring harness.

Relieve fuel pressure

Remove the retaining clip from the fuel injector.

Remove the fuel line connection from the injector

Carefully clean debris from the interface surfaces. Do not damage seal mating surfaces.

Remove the injector from the manifold

Apply a light coating of a lubricant to both the upper and lower injector seal ring of the

replacement injector.

Install the new injector into the manifold. Check that the injector is installed in the original

orientation to maintain proper spray targeting, and that the retaining clip is properly seated

on the injector and the fuel line

Install the retaining clip after connecting the fuel line

Tighten the injector mounting to the desired torque as mentioned in the manufacturer

manual

Tighten the fuel line

Re-install the injector electrical connector

Check for fuel leaks with the key “on” and the engine “off”

Start engine and verify proper operation.

or spray pattern, do not rotate the injector in the fuel rail assembly to install the injector

electrical connector. This may dislodge the retaining clip, and result in improper spray

orientation

4.Replacement Techniques

WARNING:

The injector and all associated hardware may be extremely hot.

Shut off ignition.

Disconnect negative battery cable to avoid possible fuel discharge if an accidental attempt

is made to start the engine.

Disconnect the electrical connector from the injector wiring harness.

Relieve fuel pressure

Remove the retaining clip from the fuel injector.

Remove the fuel line connection from the injector

Carefully clean debris from the interface surfaces. Do not damage seal mating surfaces.

Remove the injector from the manifold

Apply a light coating of a lubricant to both the upper and lower injector seal ring of the

replacement injector.

Install the new injector into the manifold. Check that the injector is installed in the original

orientation to maintain proper spray targeting, and that the retaining clip is properly seated

on the injector and the fuel line

Loading...

Loading...