--- 23 ---

a Inaccurate

squareness between

the turn table and the

saw blade causes the

saw blade to cut into

the workpiece at an

angle.

b Excessive deflection

of the saw blade

(Excessive vibration)

c Inaccurate

squareness between

the fence and the saw

blade

d Inaccurate surface

flatness of the fence

causes workpiece to

move irregularly,

causing poor

squareness of cut

surface.

e Inaccurate surface

flatness of the turn

table

• Adjust squareness with the

Nylock Bolt M8 x 25 [35].

• Replace the Hinge [7], Gear

Case [85] or the Turn Table

[38] (if deformed).

• Replace the TCT Saw Blade

255 mm [118].

• Check for surface defects on

Washer (A) [117] and

Washer (B) [120], and repair

with a file as necessary.

• Replace Washer (A) [117]

and Washer (B) [120].

• Loosen the Bolt (W/Washers)

M8 x 35 (Black) [30] and

adjust the squareness.

• Replace Fence (A) [46] or

Fence (B) [31].

• Loosen the Bolt (W/Washers)

M8 x 35 (Black) [30] and

adjust the squareness.

• Replace Fence (A) [46] or

Fence (B) [31].

• Replace the Turn Table [38].

0.15/100

(Dummy disc)

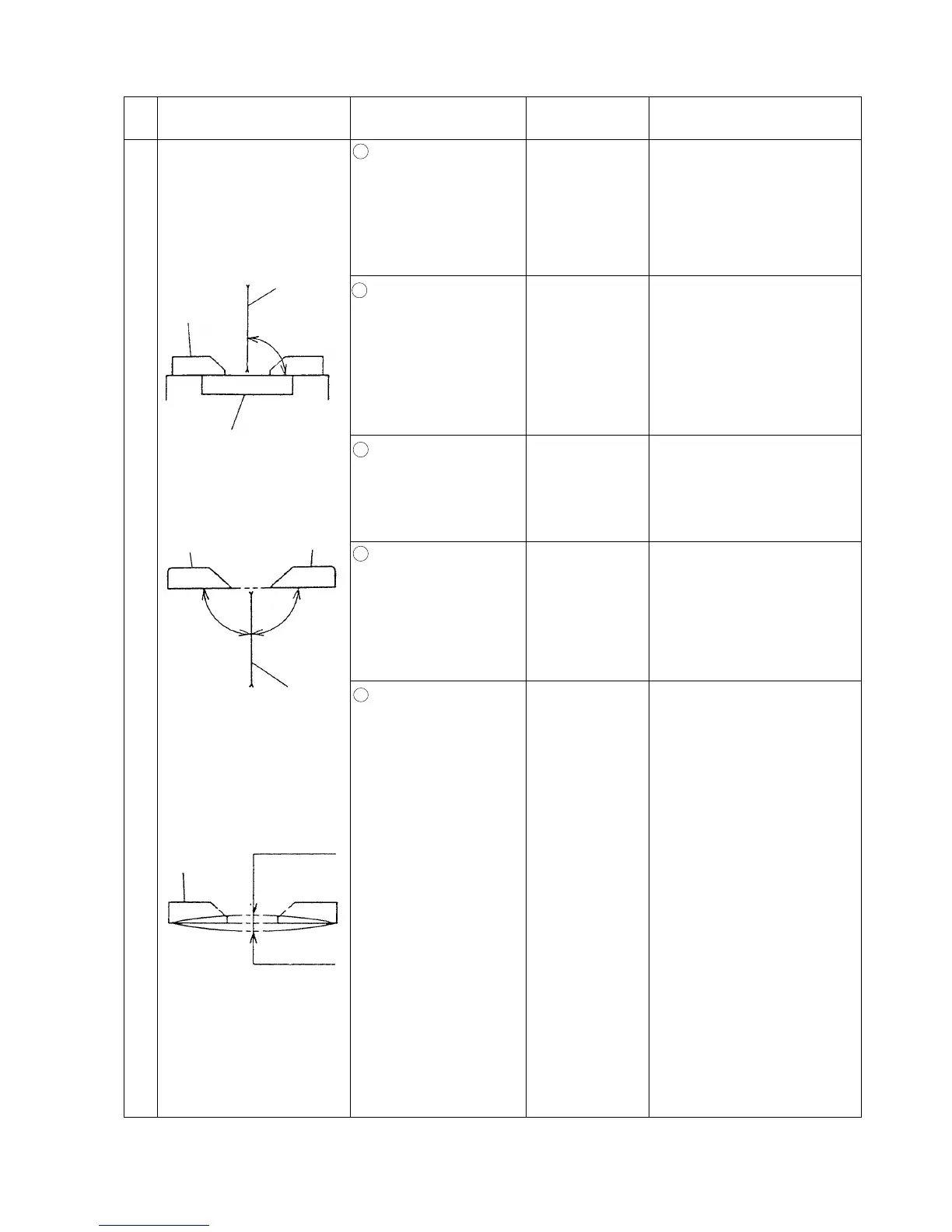

(Fig. 25)

0.2/245

(Dummy disc)

0.15/100

(Fig. 26)

0.1 or less

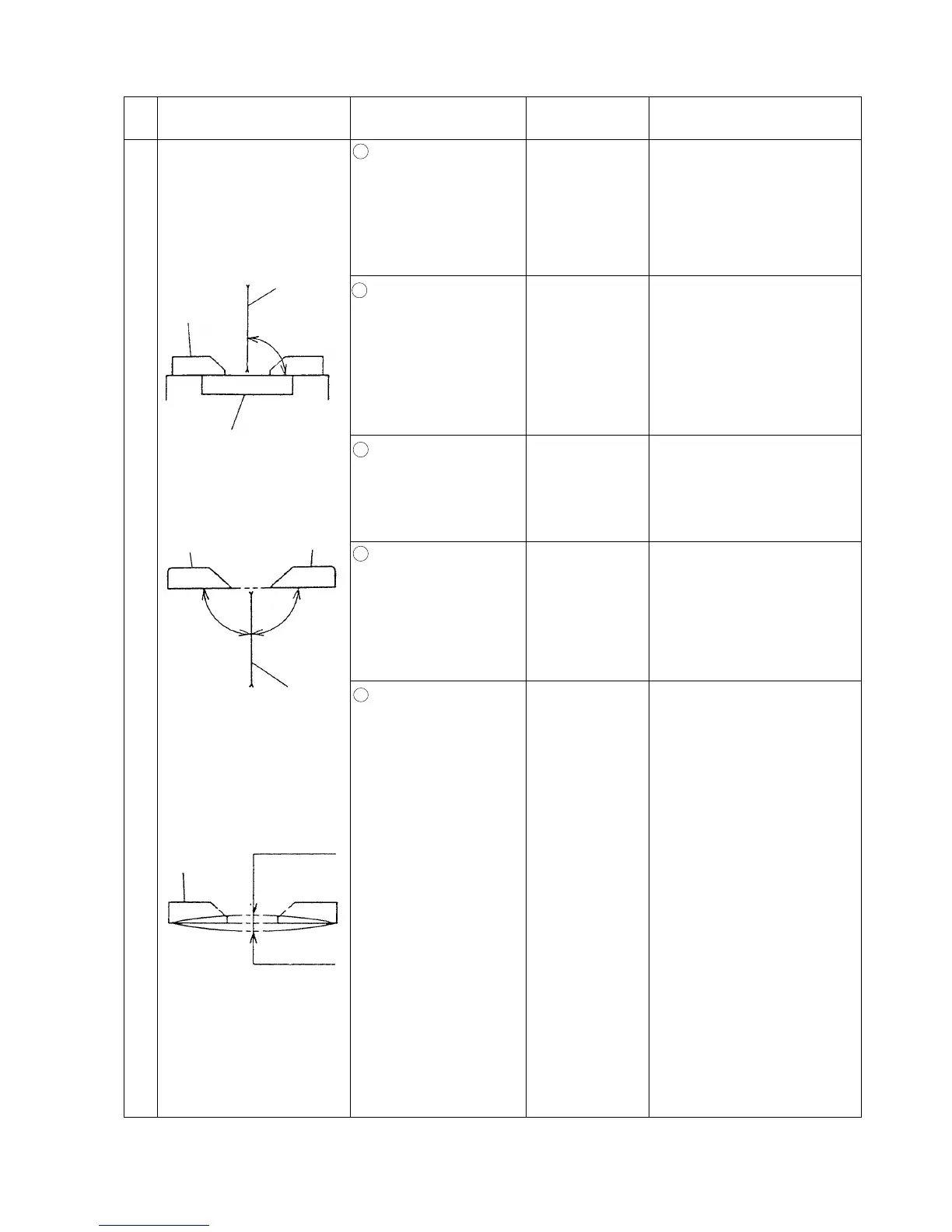

(Fig. 27)

0.1 or less

12. REPAIR GUIDE

1

Inaccurate cutting

•••

Inaccurate

squareness of the

cut surface

•••

Cut surfaces do not

fit together properly.

Fig. 25

Fig. 26

Fence

Saw blade

Squareness

0.15/100

Saw blade

Fence (A)

0.1 or less

Fig. 27

Fence (B)

Fence (A)

Item Phenomenon Cause

Factory

standard

Inspection, repair or

adjustment

Unit: mm

Turn table

Squareness

0.15/100

Squareness

0.15/100

0.1 or less

Fence (B)

Loading...

Loading...