--- 37 ---

11. REPAIR GUIDE

No. Problem Possible cause

Factory rated

value

Remedy

1

Low cutting accuracy

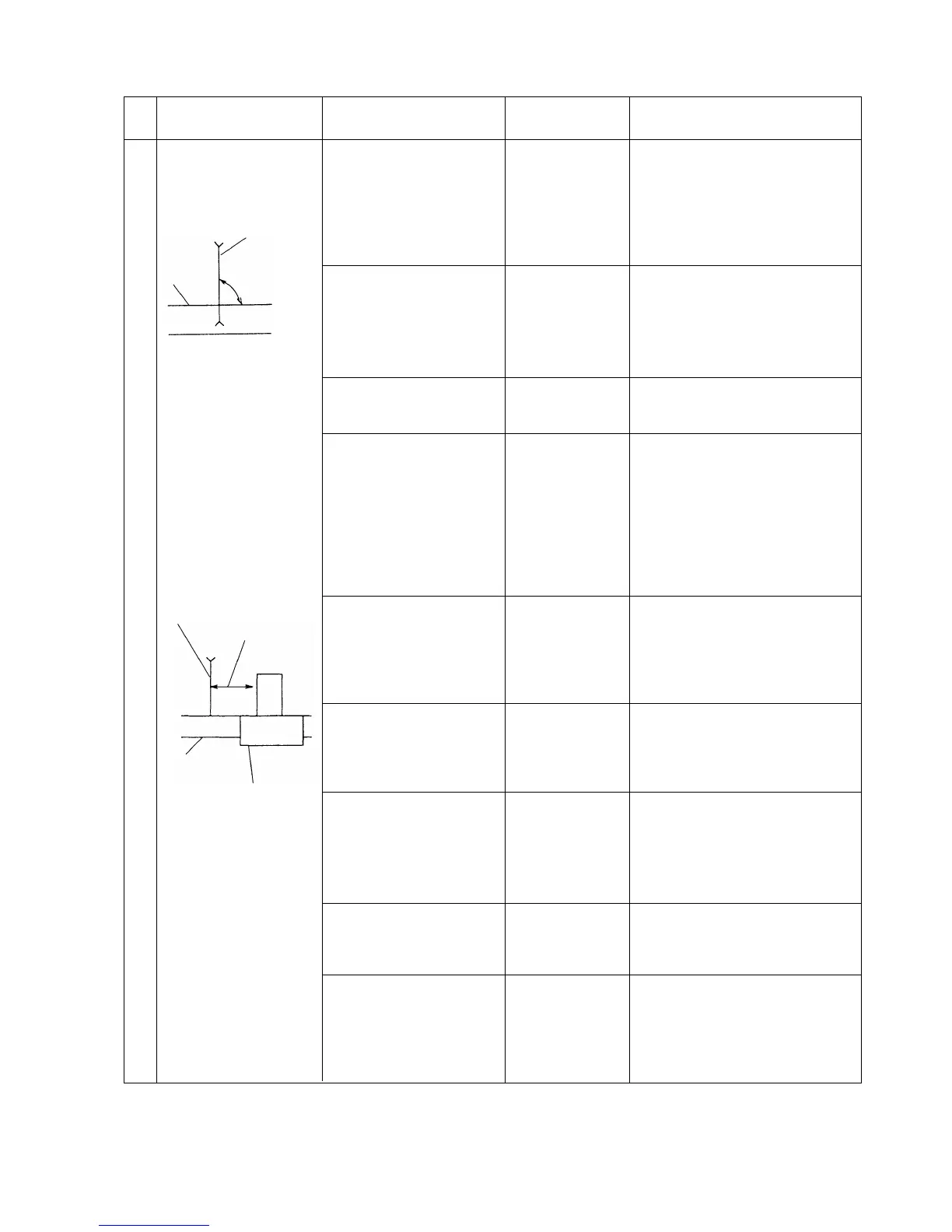

--- poor squareness of

cut surface

a) Because of poor

squareness between

the table and saw

blade, the saw blade

enters the material at

a slant.

0.4/60

(Dummy disc)

(Fig. 40)

• Readjust the squareness of the

saw blade using the M6 x 20

Seal Lock Screw [27].

b) Large run out of saw

blade.

(Large vibration)

0.38/230

(Dummy disc)

• Replace the Saw Blade [704].

• Check Washer (A) [75] for

dents, etc. If any, remove with

a file.

• Replace Washer (A) [75].

c) Poor parallelism of

table upper surface.

1.0 /200

or under

• Replace Table [33].

d) Poor parallelism

between the table and

the extension wing.

1.5/200

or under

• Loosen the M8 x 20 Bolt (W/

Washers) [107], and readjust

the parallelism between the

Table [33], and Extension Wing

(R) [35] and Extension Wing

(L) [29].

• Replace Extension Wing (R)

[35] or Extension Wing (L) [29].

e) Poor parallelism

between the miter-

gauge groove and

saw blade.

0.4/200

(Dummy disc)

• Loosen the M6 x 25 Flat Hd.

Screw [26], and readjust the

parallelism between the miter-

gauge groove and the saw

blade.

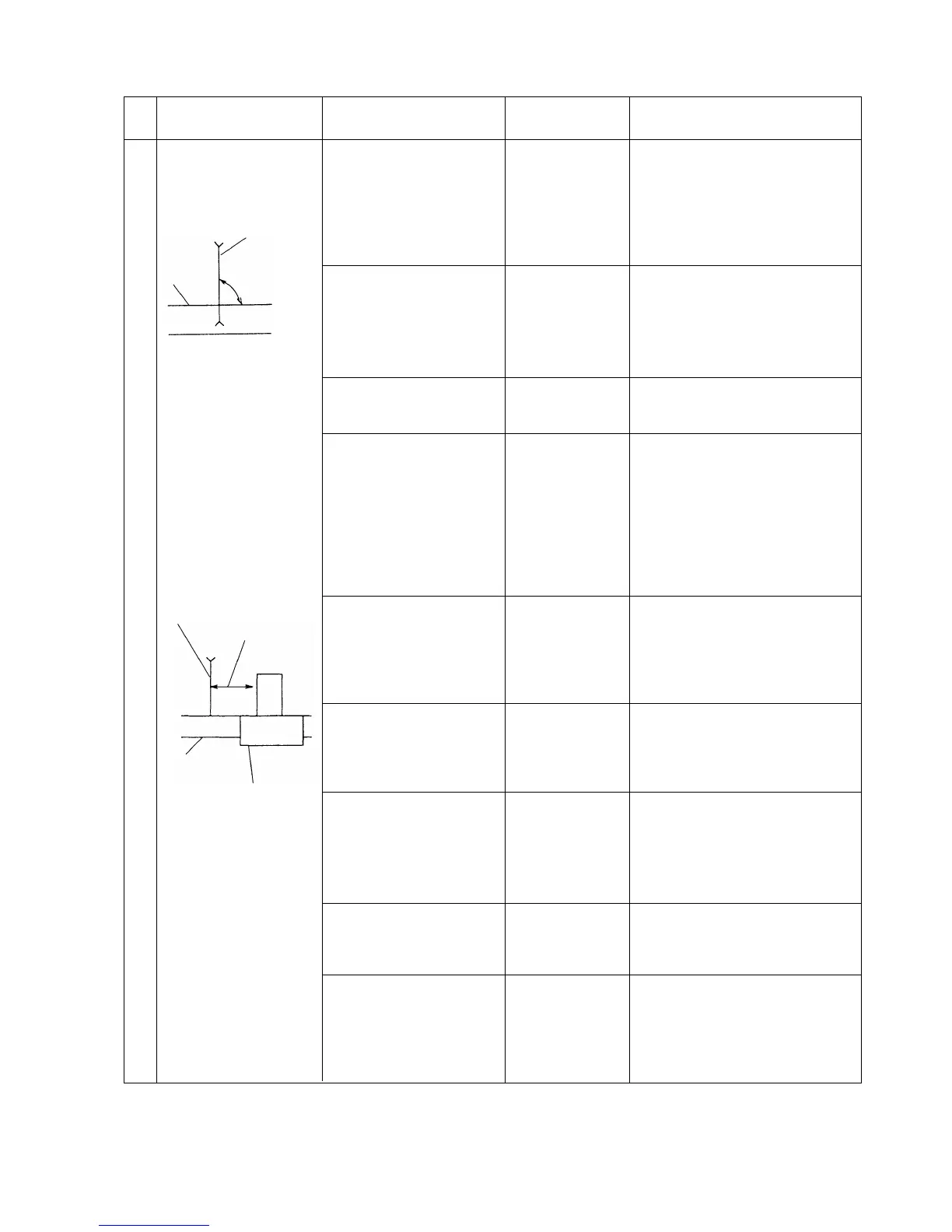

f) Poor parallelism

between the rip fence

and saw blade.

1.0/200

(Dummy disc)

(Fig. 41)

• Loosen the M6 x 12 Bolt [43],

and readjust the parallelism

between the rip fence and the

saw blade.

g) A too fast cutting

speed causes the saw

blade to deflect and

results in low

accuracy.

------

• Slow down the cutting speed.

(Proper speed is 7 seconds for

50 mm rectangular lumber.)

h) Excessive force is

applied because of a

dull saw blade.

------

• Sharpen the Saw Blade [704].

• Replace the Saw Blade [704].

i ) Deformation of the

material such as a

curvature or bend

causes the material to

move during cutting.

------

• Correct the curvature or bend

by planing the material, and cut

again.

Fig. 40

Fig. 41

Table

Saw blade

Squareness

0.4/60

Saw blade

Table

Rip fence

Parallelism

1.0/200

(Note) Unit:

mm

/mm

(Note) Unit:

mm

/mm

Loading...

Loading...