Perform the work according to “Dissolution and Composition Manual of Hitachi Half Sealed

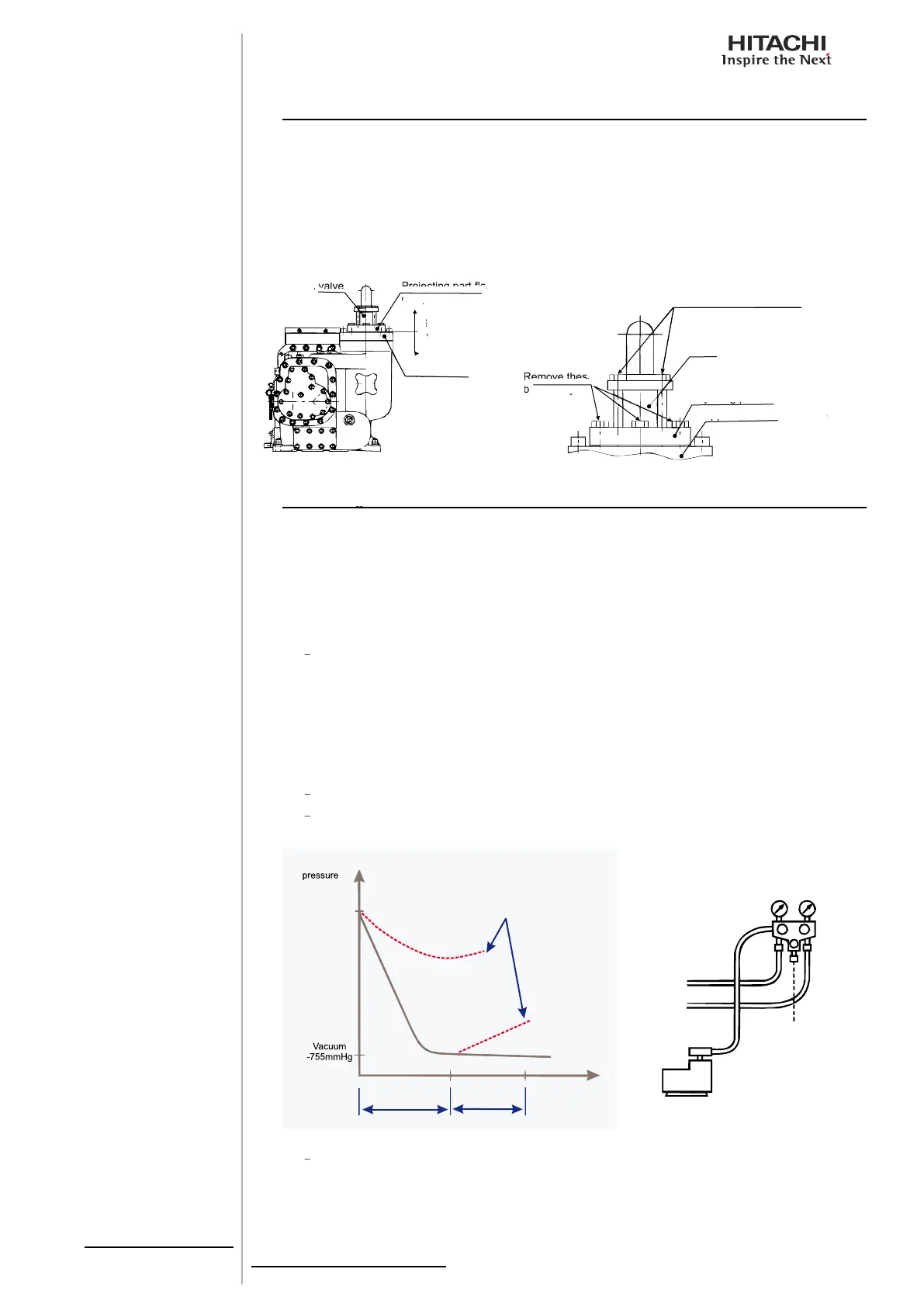

When compressor is removed from refrigeration cycle, high pressure part should be separated

between projecting part fl ange of compressor and upper cover of oil separator. Do not

be separated between check valve and projecting part fl ange of compressor, or collected

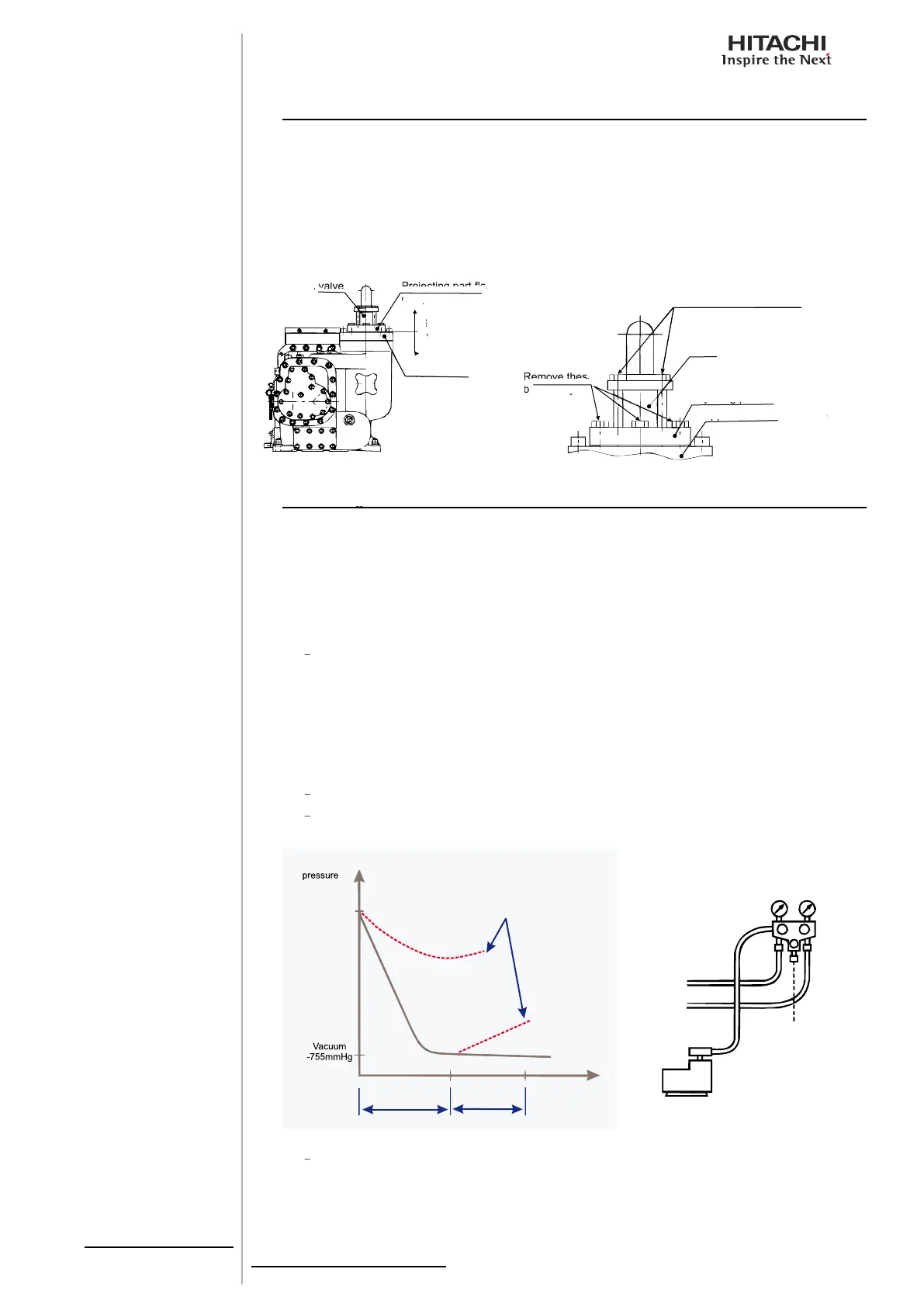

6.10. Vacuuming Procedure

6.10. Vacuuming Procedure

6.10. Vacuuming Procedure

Although refrigerant is collected to airside heat exchanger by the above collection operation,

it is necessary to be vacuumed due to that refrigerant cycle of low pressure side pipe and of

water side heat exchanger are open.

Vacuum should be performed in the following 2 positions.

Stop valve for refrigerant insertion ((D) part)

Check joint of compressor suction side ((E) part)

*Capillary for compound gauge in low pressure side is installed in check joint. This

capillary should be removed from check joint.

Vacuuming procedure is shown in the following.

Manifold valve, vacuuming pump and vacuuming gauge for R407C are connected.

Operate vacuuming pump for at least 1~2 hours until vacuum grade be below

Vacuum gauge should be used to measure a target vacuum, however, it is

impossible to read the vacuum gauge installed in the manifold very accurately.

It is recommended to use a digital vacuum measure device, available in the

Projecting part fl ange of

Projecting part fl ange of

Projecting part fl ange of

Do not remove these bolts

or refrigerant is ejected

or refrigerant is ejected

Projecting part fl ange of compressor

Projecting part fl ange of compressor

Projecting part fl ange of compressor

Projecting part fl ange of compressor

Upper cover of oil separator

Upper cover of oil separator

Upper cover of oil separator

Upper cover of oil separator

Upper cover of oil separator

Upper cover of oil separator

Loading...

Loading...