FEATURES AND BENEFITS

2

3

"

Energy Saving

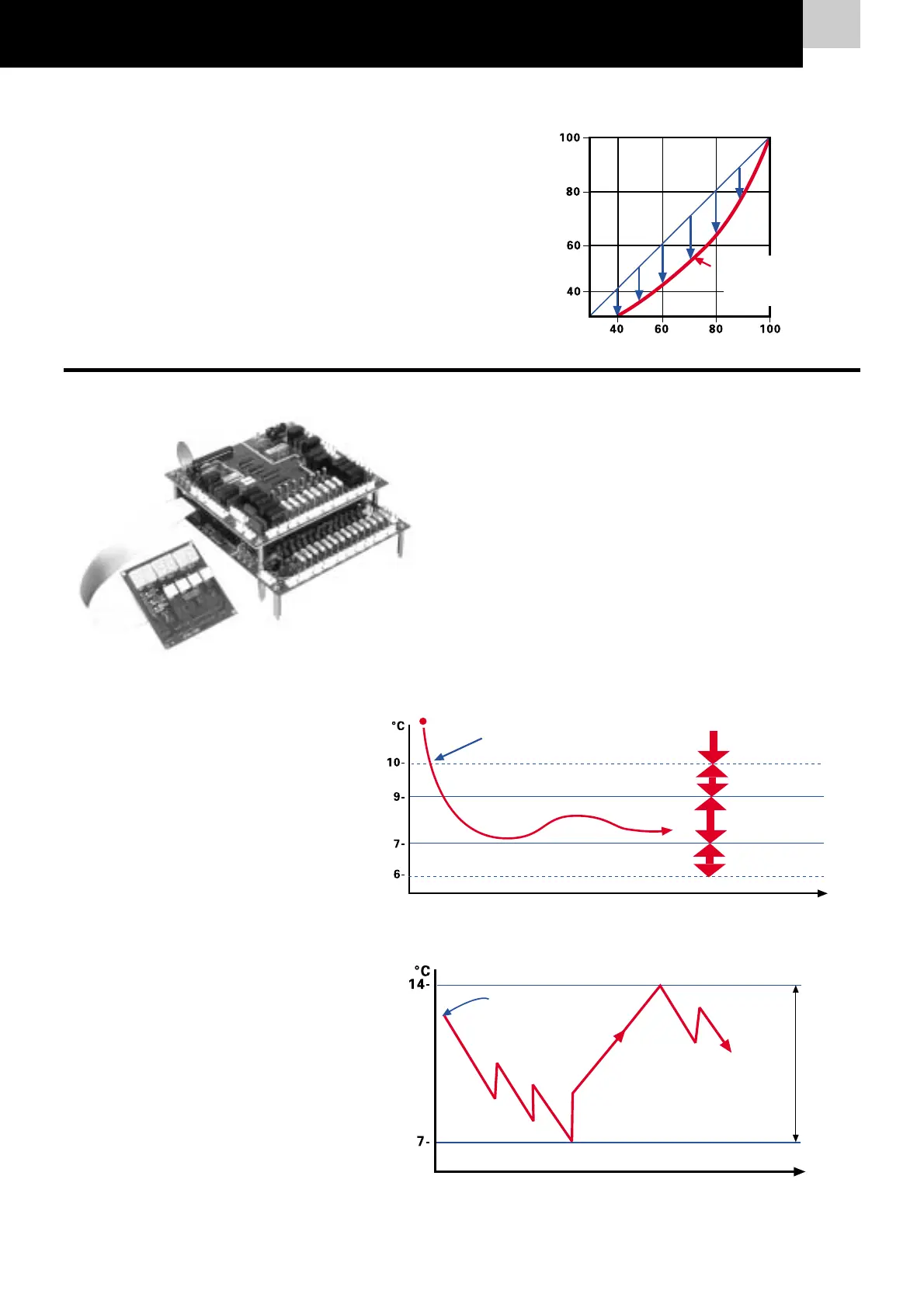

Thanks to Continuous Capacity Control, 15~20% energy

saving is possible compared with current step control

systems due to the following:

! The cooling load can be more closely matched

! Continuous Capacity Control takes advantage of high

efficiency part load performance.

! Frequent compressor starts and stops are eliminated.

-PART LOAD PERFORMANCE-

2.3. CONTROL

"

Many Functions

Newly developed Control Board has many functions shown

below as standard.

! REMOTE/LOCAL changeover switch

! Individual Alarm

! Pump operation circuit

! Pump Freeze Protection Control

! Reverse Phase Protection

! Time Guard

! Star Delta starting Circuit

! Easy Interface

etc...

"

Precise Temperature Control

Combination of "Continuous Capacity Control

Compressor" and "HITACHI´s unique

electronic controls" enable the Chiller to

control outlet water temperature precisely,

independent of cooling load.

This control benefits not only air-conditioning

but also industrial process use.

-CONTINUOUS CAPACITY CONTROL-

-CONVENTIONAL STEP CONTROL-

MOTOR INPUT (%)

COOLING CAPACITY (%)

Continuous

Capacity

Control

Start

Outlet Water Temperature

Load Up 2

Load Up 1

(Quick cooling)

Neutral =2°C Standard

Minimum 0.5°C

Load Down

TIME

WATER TEMPERATURE

WATER TEMPERATURE

Restart

1st step

Final step

Outlet

Tem

erature

Temperature

Band 7°C

(normally)

Loading...

Loading...