Stabilizer Assembly

1) Identfiy left stab with recess for control horn.

2) Remove covering material where control

horn is glued to stabilizer.

3) Glue horn to stab using regular CA. 4) Attach center section of flying stab to

fuselage using 4 screws.

5) Test fit flying stab with spacers.

7) Using 15 min epoxy, glue brass tube to left stab with control horn and allow to cure. Install

left stab into center section with L & R spacers in place. Finally glue other stabilizer half. Set

on flat surface with tips of both halves contacting the flat surface for alignment.

**Build Note** Apply epoxy to stabilizer

halves only. Do not glue to center section.

Spacers should touch stabilizer slightly, but

not limit movement.

1) Locate the servo cutouts in wing and cut

away covering from the top and bottom.

2) Mount the wing to the fuselage, lining up the

wing mounting holes to the fuselage. Using a

black felt pen, mark the location for the aileron

servo cutouts in the wing saddle.

4) Select which fin option you will use.

Roughen fuselage at contact location with

sandpaper or a rotary tool.

3) Using a rotary tool, cut away wing saddle

material from the marked location. This allows

the wing servos to sit flush against the bottom

of the wing.

5) Glue fin to fuselage with 15 minute epoxy,

keeping the fin 90 degrees to the horizontal

stabilizer.

6) Roughen the area on each end of the brass tube

that will be inserted into the stabilizer half.

90°

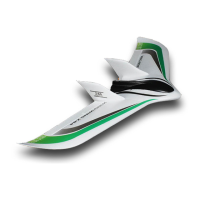

Airframe Assembly

3 4

Loading...

Loading...