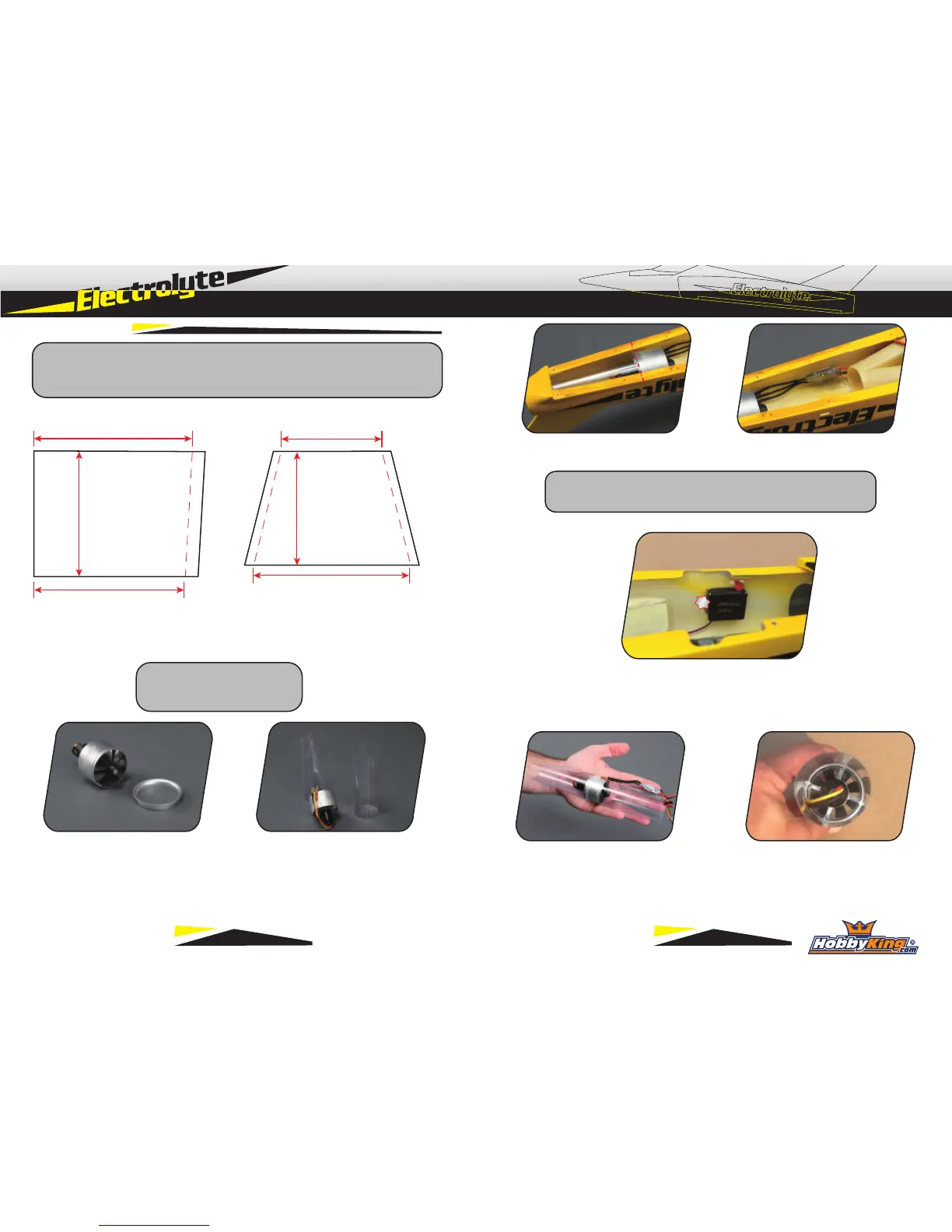

Fan Installation

**Build Note** The performance of this model lies in attention to detail when

installing the ducting. The templates below are rough estimates and may need

slight adjustments to fit your exact model since each one is slightly different.

1) Using the templates above as guides, cut front and rear ducting pieces from the included

clear plastic sheet. Each template above has excess material shown (beyond the dashed line)

that helps to make taping the ducting together easier. Suggest 10mm for forward duct, and

8mm each side of rear duct.

Forward Duct Rear Duct

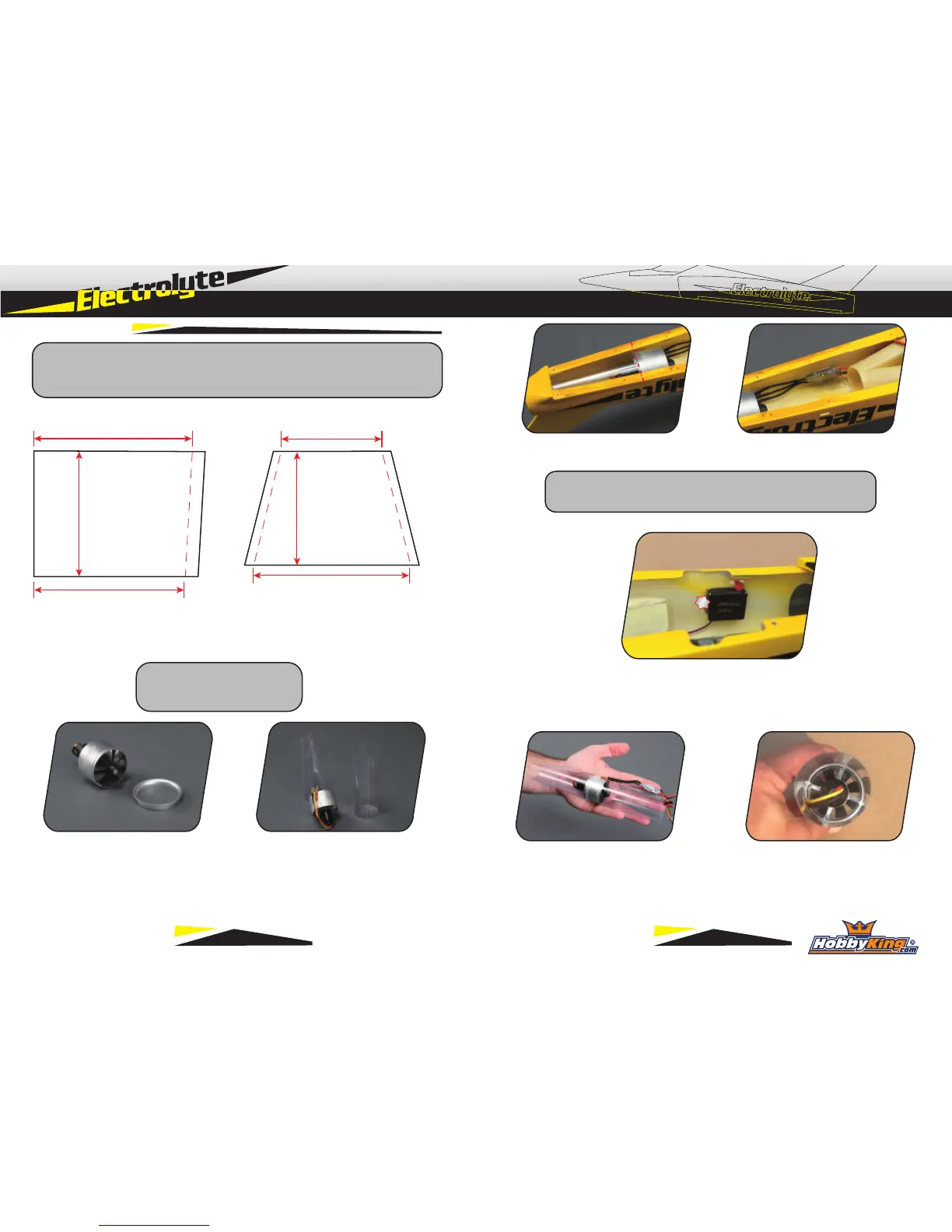

2) Remove front lip piece from fan. This

will not be used for the Electrolyte.

*Thrust Tube Exit Diameter*

- 30mm Yields optimal speed

- 33~34mm Yields better static thrust

3) Using clear tape, tape together the ducting pieces.

For tightest fit of rear ducting, roll it tightly around fan

prior to taping. Make front and rear duct pieces.

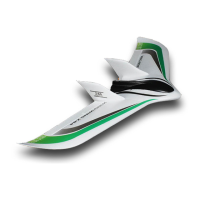

4) Test fit fan and ducting into fuselage. Back edge of fan shround will align to 3rd set of screw

holes. (From back) ESC will mount on right side of fuselage, opposite the elevator servo.

6) Using clear tape, carefully attach ducting to fan to make complete unit. Check your motor

for proper rotation direction prior to installation. Route motor wires as shown, minimizing

force on the wires to prevent long term damage.

5) Mount elevator servo to left fuselage side

using 15 minute epoxy. Install servo arm and

center servo before gluing to fuselage.

120mm

104mm

138mm

132mm

137mm

100mm

**Build Note** Aft tail mount blocks in fuselage may need slight

bevel to allow rear ducting to be inserted without distortion

7 8

Loading...

Loading...