HOLMS 300

© HOLMS INDUSTRI AB, ALL RIGHTS RESERVED 141204. 15

easiest thing is to empty the tank first and then run the

pump dry for 20-30 seconds.

The water tank has been designed so that the suction pipe

of the pump ends a little above the bottom of the tank.

This is so that rough particles remain in the container

rather than being drawn up. When emptying the tank,

therefore, a bottom plug must be removed, see figure 7.

Operating with side brush (extra equipment)

The Holms 300 can be fitted with one or two side brushes

for more efficient sweeping up against kerbs, etc. These

can be optionally fitted on the right, left or both sides.

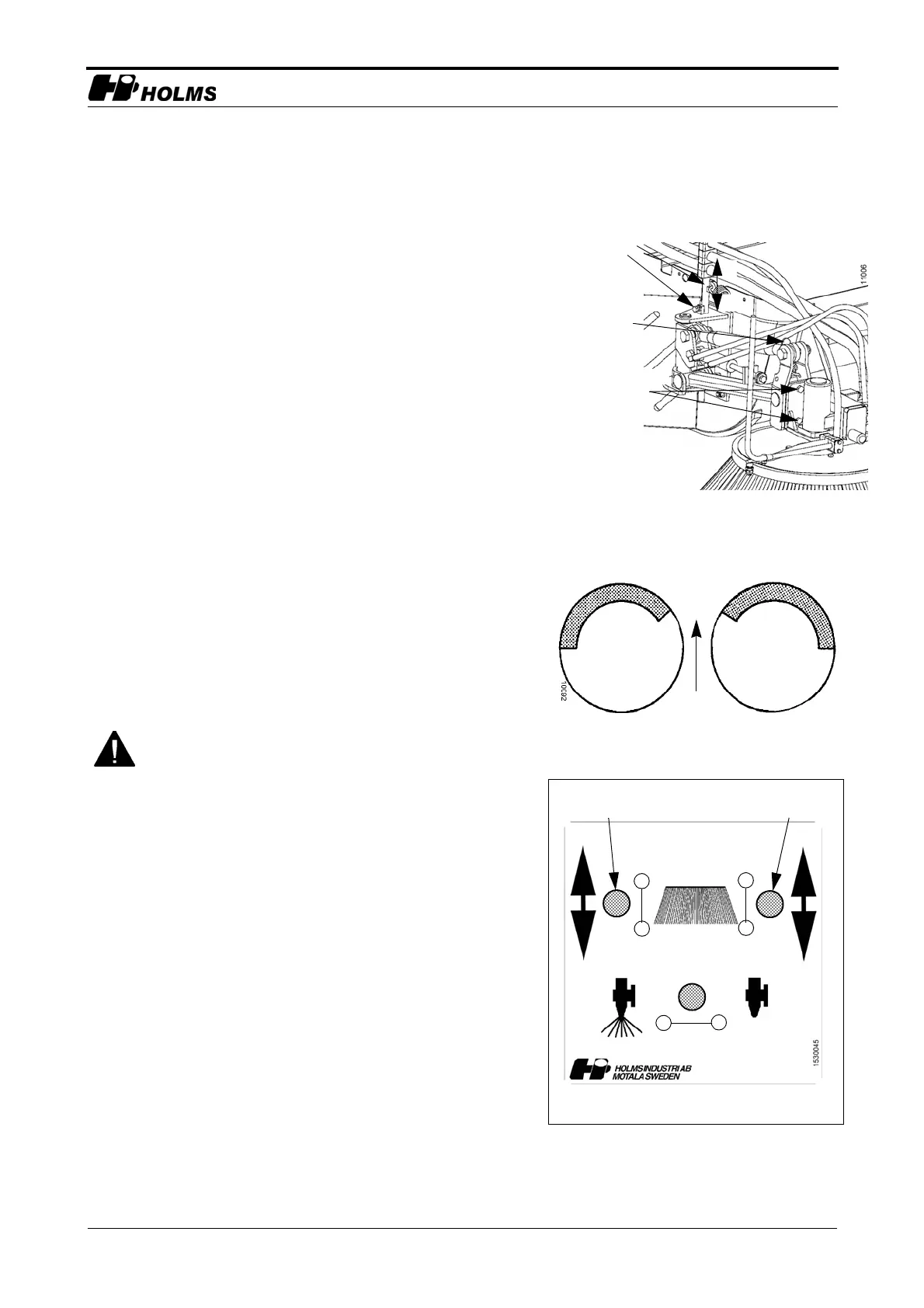

Setting the side brush

For information on connecting side brushes, see

“Connection of side brush (extra equipment)” on

page 14.

The sideways inclination of the side brush is adjusted by

loosening the two nuts (see figure 8), angling the brush

and tightening the nuts.

The forwards inclination of the brush is adjusted by

loosening the lock on the rigging screw (see figure 8) and

fixing the rigging screw so that the desired inclination is

achieved. Secure using the lock.

The pressure of the brush against the ground can be

adjusted by loosening firstly the nut and then the screw

that holds the balancing rod. Then, push down the rod for

increased ground pressure or pull it up for decreased

ground pressure, see figure 8. Then, secure the screw

and nut.

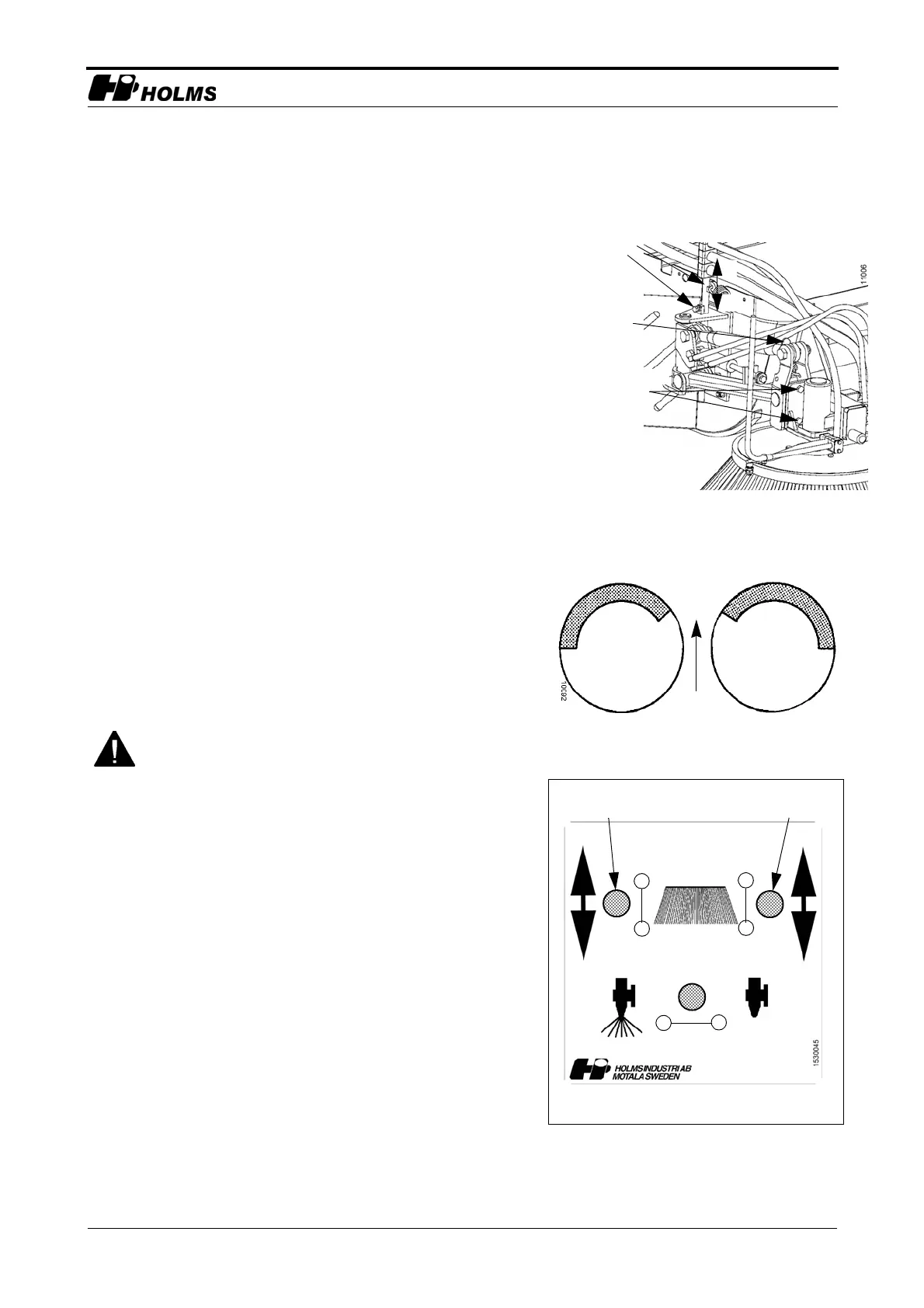

By allowing the side brush to rotate for a while against

the ground and then raising it, the brushing pattern can be

studied. Only the forward, outer part should touch the

ground, see figure 9.

Operation

All manoeuvring of the side brush requires the main

brush (roller) to be connected (rotating). The side brush

is started by moving the switch into position 2 (see figure

10). The brush then starts and moves down and out into

the operating position.

Always turn the side brush and sweeper roller off

before making any adjustments.

Rigging screw's

lock

Balancing rod

nut/screw

>

<

vertical position

Nuts for adjusting

(reverse side)

8.Setting the side brush

Right

fitting

Left

fitting

9.Brushing pattern

Switch for side brush

left-mounted.

Switch for side brush

right-mounted.

2

1

2

1

3

4

Position 1: Switched off

Position 2: Operating position

Position 3: Sprinkler on

Position 4: Sprinkler off

10.Control unit

Loading...

Loading...