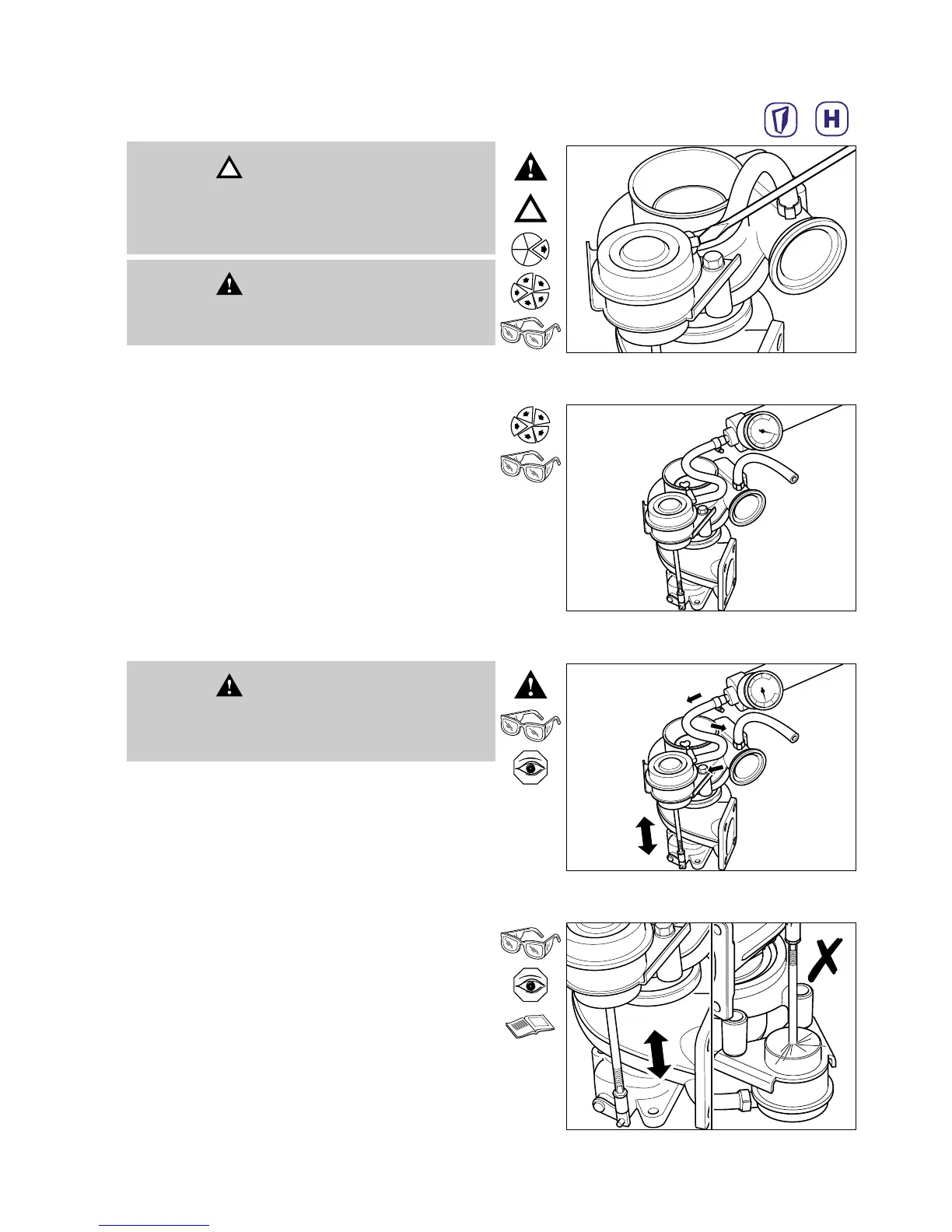

Place the turbocharger on a suitable workbench. Using

a small flat screwdriver, carefully remove the hose clip

(75) and discard. Pull the flexible hose from the

actuator spigot.

HX25/25W/27W Service Repair Manual Component Testing and Replacement

Wastegate Actuator Checks

4:14

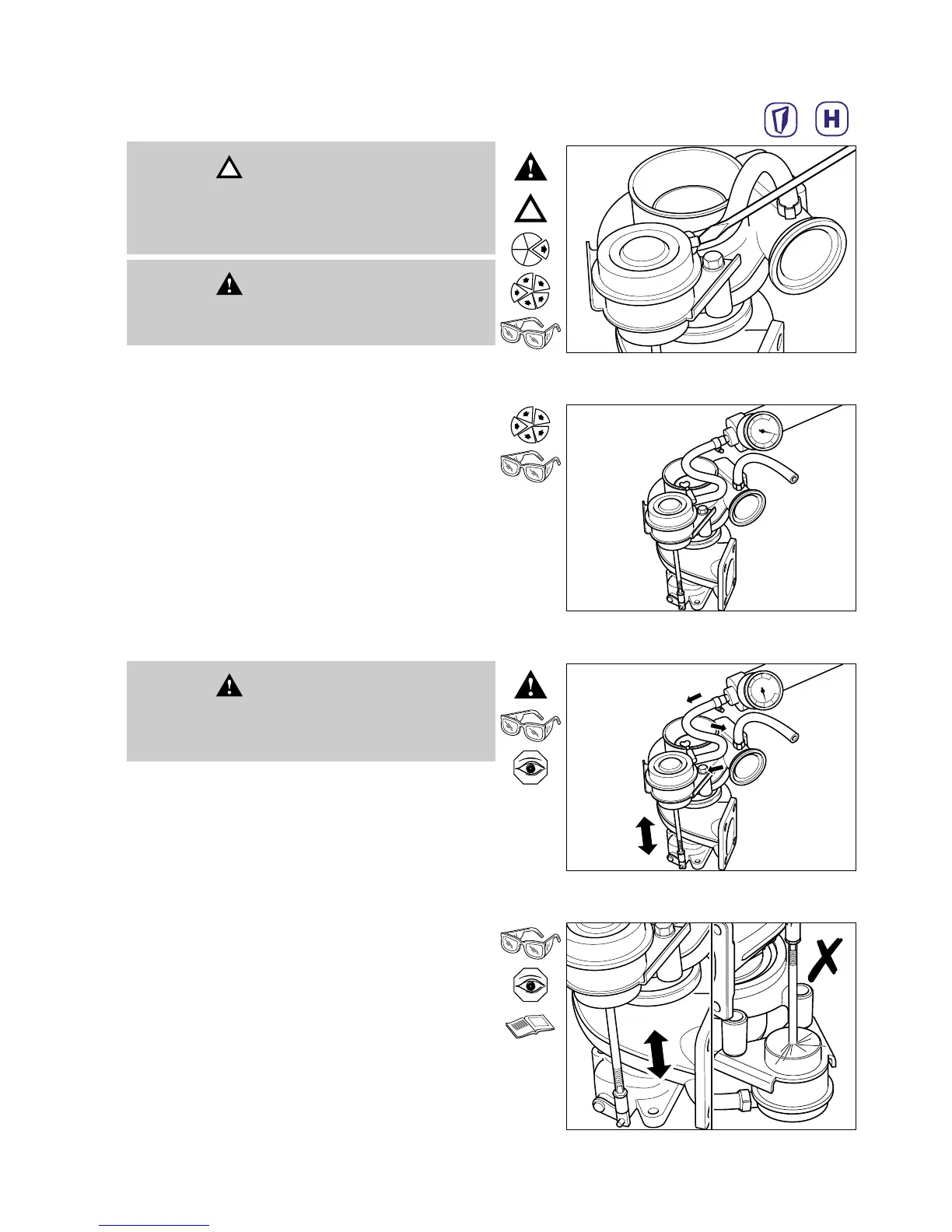

Connect and secure the hose from a regulated

compressed air supply to the actuator spigot.

Carefully apply pressure to the actuator from the

regulated compressed air supply Max 300 kPa

(45 lbf/in

2

) and check for actuator movement.

If movement is confirmed when using remote air supply

check that turbocharger hose assembly is not

damaged. If damage is found, replace with new hose

and clips.

Seized Actuator Check

If rod does not move check wastegate actuator for air

leaks. If no air leak is found and rod does not move,

check valve mechanism for seizure according to

procedure defined in Wastegate Mechanism Check.

Warning

Wear safety glasses at all times during the

disassembly process.

Caution

Do not remove turbocharger from engine unless an

actuator check is impractical due to space or access

limitations or where an on-engine check has shown a

problem exists.

Warning

Avoid touching the wastegate rod end area as finger

injury may result from sudden movement of the

assembly when air pressure is applied.

Loading...

Loading...