HX25/25W/27W Service Repair Manual Component Testing and Replacement

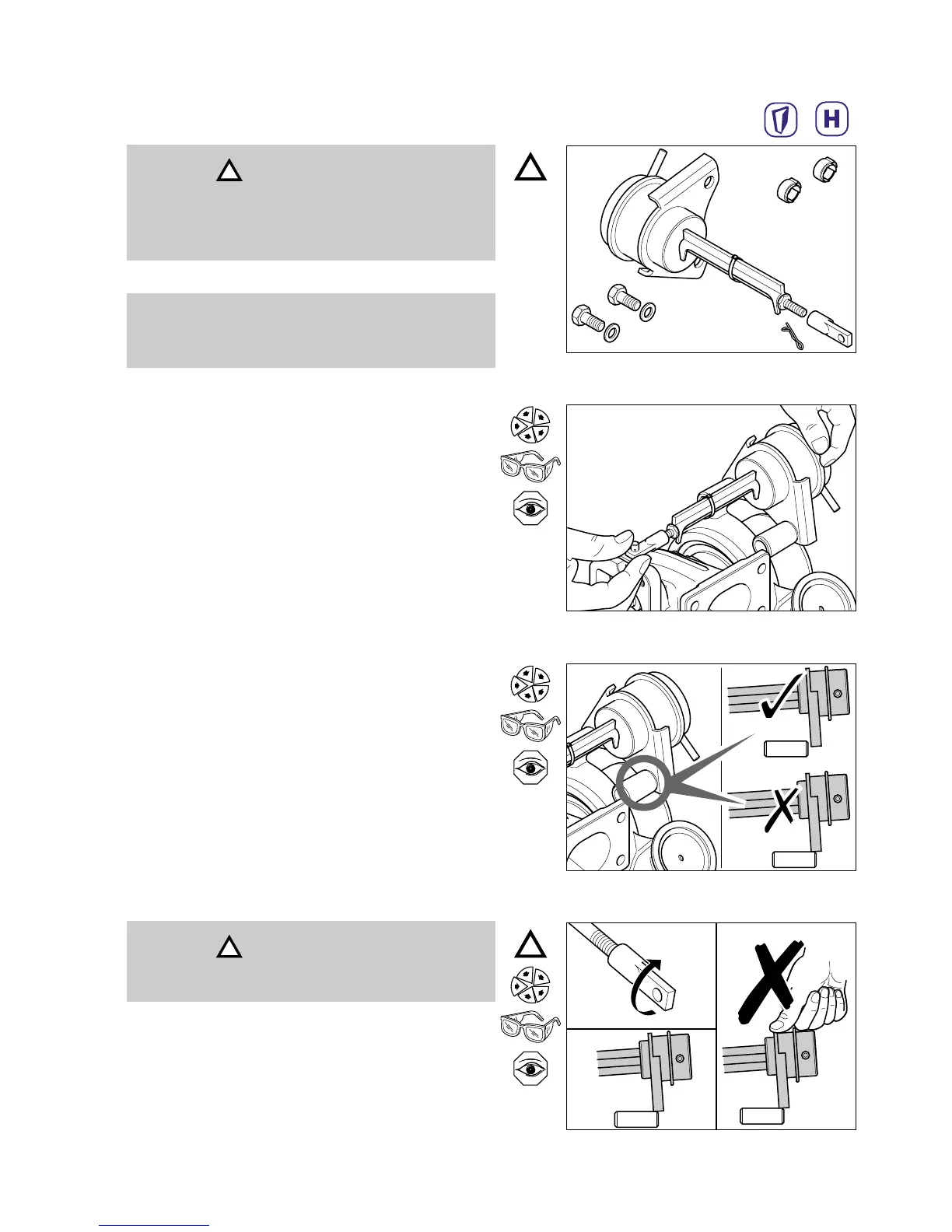

Wastegate Actuator Replacement

4:18

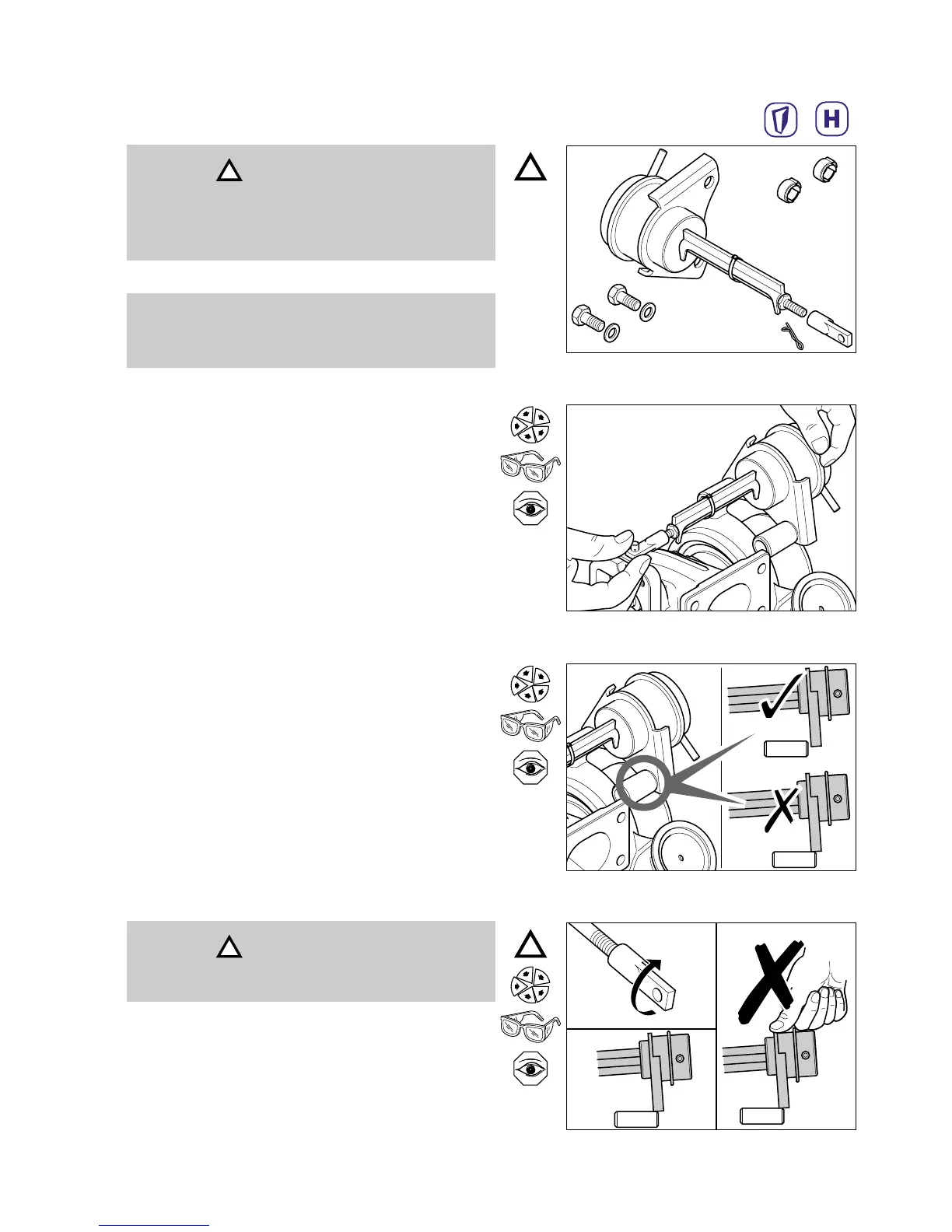

Thread new end link several turns on to the shaft of the

new pre-set actuator assembly.

Hold the actuator assembly with the spine of the spacer

piece upright. Rotate the valve mechanism lever arm to

close the wastegate valve (pushed towards the

compressor end). Fit end link over the lever arm pin.

Attempt to slide the actuator bracket over its retaining

lugs. If the actuator bracket fouls on the lugs or there is

significant clearance between bracket and lugs,

actuator rod length requires adjustment.

To adjust the length of the actuator assembly, remove

from the turbocharger. Rotate the end link to shorten or

lengthen the rod as appropriate. Re-fit, until the

underside of the actuator bracket will just fit over the

mounting lugs with less than 0.5 mm (0.020 in) gap.

The rod length setting is correct if, by rotating end link

clockwise by a half turn, the actuator bracket fouls on

the lugs.

Caution

Contact your local approved agent for the correct

replacement actuator kit (74). It is important to quote

the correct turbocharger assembly number to ensure

supply of the correct pre-set actuator.

Caution

Do not apply force to push the actuator on to its

mounting lugs.

Note

When refitting existing actuator the end link will be

locked in the correct setting.

Loading...

Loading...