28 KGZ Series | Version 2.02 | EN

Care, maintenance and repairs

All protective and safety equipment must be immediately

reinstalled after having completed repair and main-

tenance work.

1. When all the adjustments, settings or maintenance

have been done, make sure that all keys and wren-

ches have been removed and that all screws, bolts

and other fittings are securely tightened.

2. Keep the tool's air vents unclogged and clean at all

times. Occasionally you may see sparks through the

ventilation slots. This is normal and will not damage

your power tool.

3. Regularly check to see if any dust or foreign matter

has entered the grills near the motor and around the

trigger switch. Use a soft brush to remove any accu-

mulated dust.

4. Wear safety glasses to protect your eyes whilst

cleaning.

5. If the body of the saw needs cleaning, wipe it with a

soft damp cloth. A mild detergent can be used but no-

thing like alcohol, petrol or other cleaning agent.

6. Never use caustic agents to clean plastic parts.

7. Store the tool, instruction manual and accessories in a

secure place. In this way you will always have all the

information and parts on hand.

Lubrication Model KGZ 255 E

All the motor bearings in this tool are lubricated with a

sufficient amount of high-grade lubricant for the life of the

unit under normal operating conditions; therefore, no

further lubrication is required.

Lubricate the following as necessary:

- Tapping: Apply light machine oil at the indicated

points.

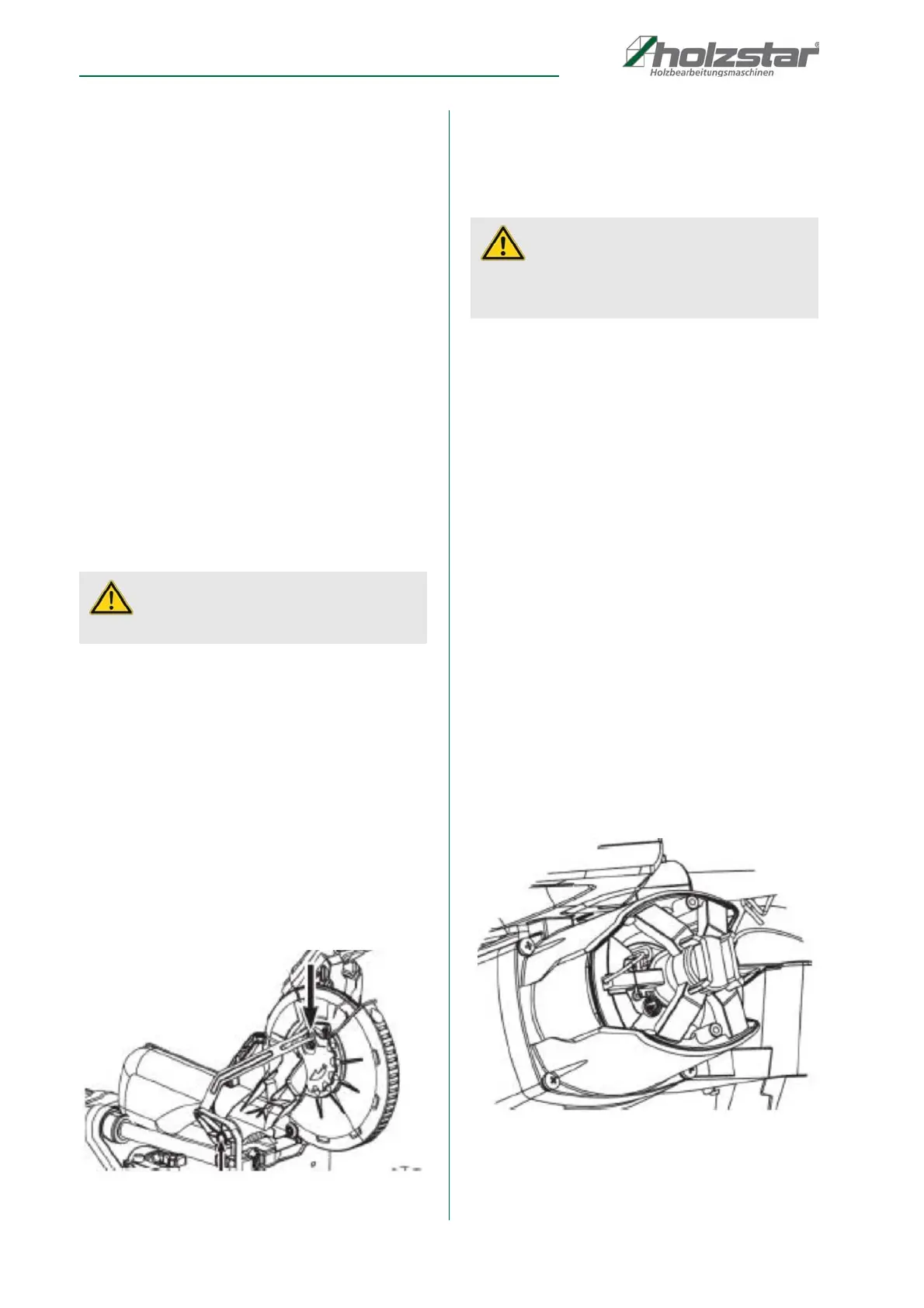

Fig. 18: Lubrication point KGZ 255 E

The central point of plastic protection: Use light house-

hold oil (sewing machine oil) on metal-metal or metal-

plastic protective contact surfaces to ensure smooth,

quiet operation. Avoid excessive oil as sawdust will ad-

here to it.

Replacing the Carbon Brushes (Model KGZ 255 E)

Replace both carbon brushes when either has less than

6 mm) length of carbon remaining, or if the spring or wire

is damaged or burned.

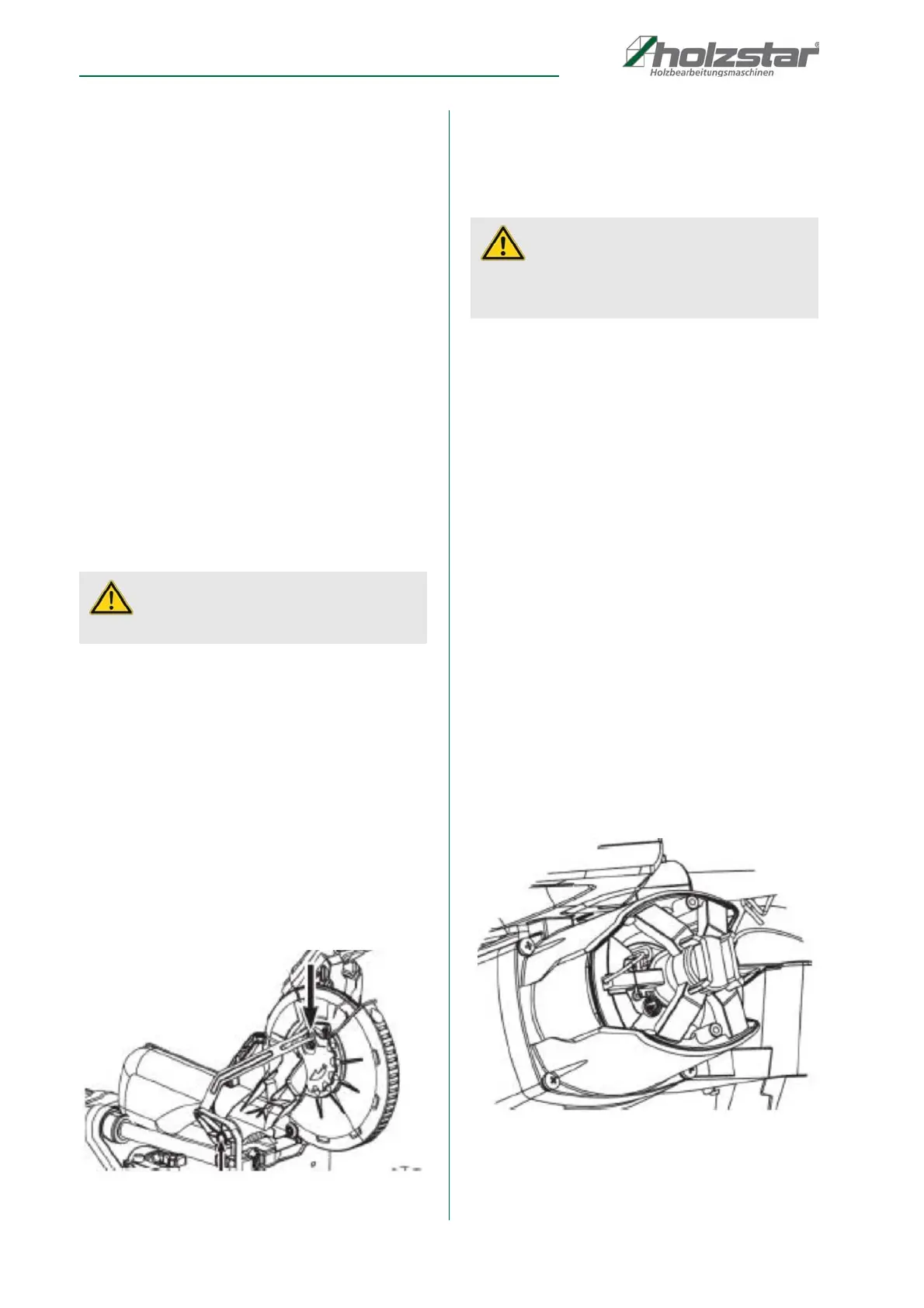

Step 1: To inspect or replace brushes, first unplug the

saw.

Step 2: Remove the two screws on the back cover of the

motor and take the cover off.

Step 3: Move the coil spring which presses on the car-

bon brush to other side to free the carbon brush.

Step 4: Pull out the brush and the wire which connects it

to the holder.

Step 5: Replace it for a new carbon brush.

Step 6: Then replace the carbon brush on the other side

of the motor.

Step 7: To reassemble, reverse the procedure. Tighten

two screws on the back cover.

Fig. 19: Replacing the carbon brushes

This will avoid a break-in period that reduces motor per-

formance and increases wear.

ATTENTION!

Water must never come into contact with the saw.

DANGER!

The grease in the gearbox must be replaced after

extensive use of the tool. Ask an authorized service

representative to perform this service.

Loading...

Loading...