I

Lubrication Svstem

I

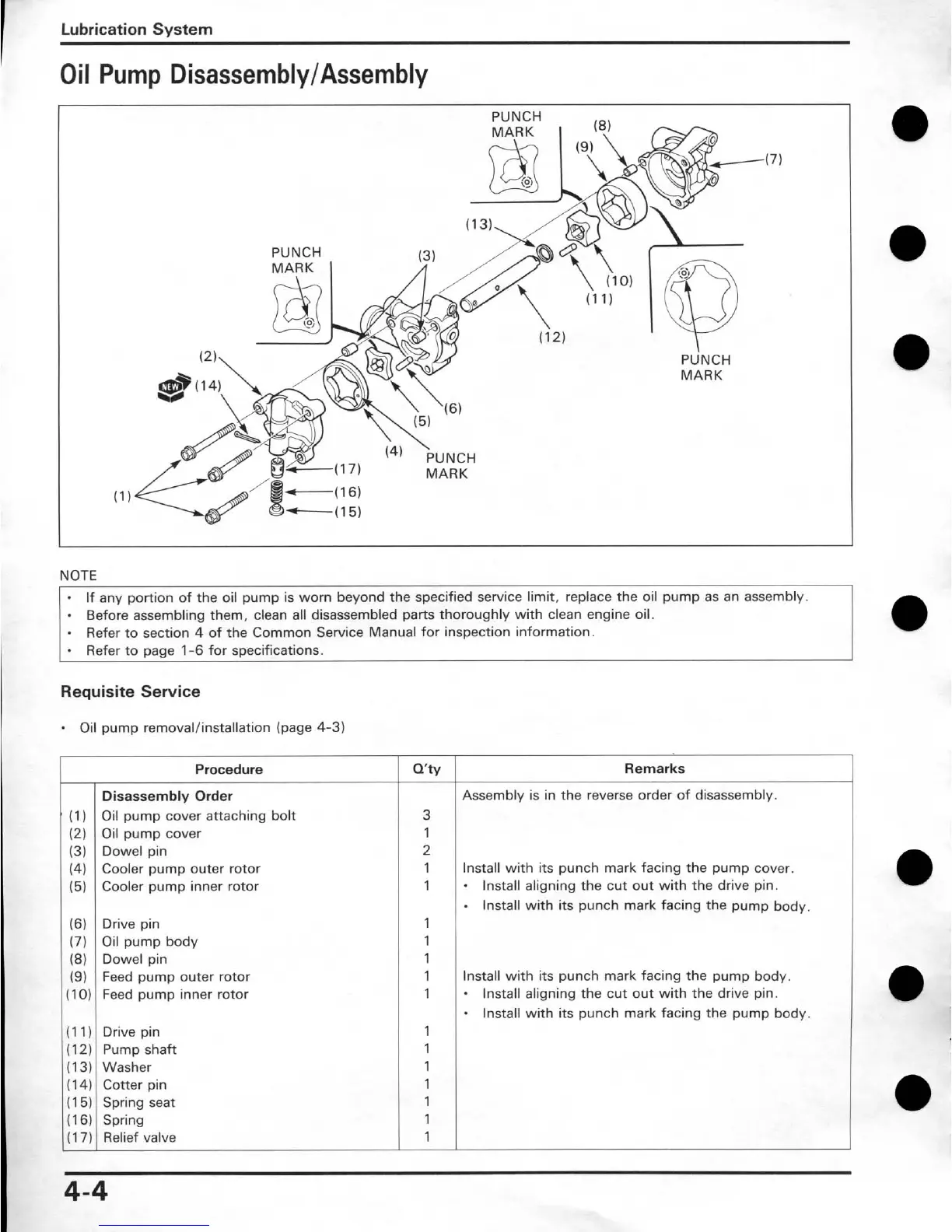

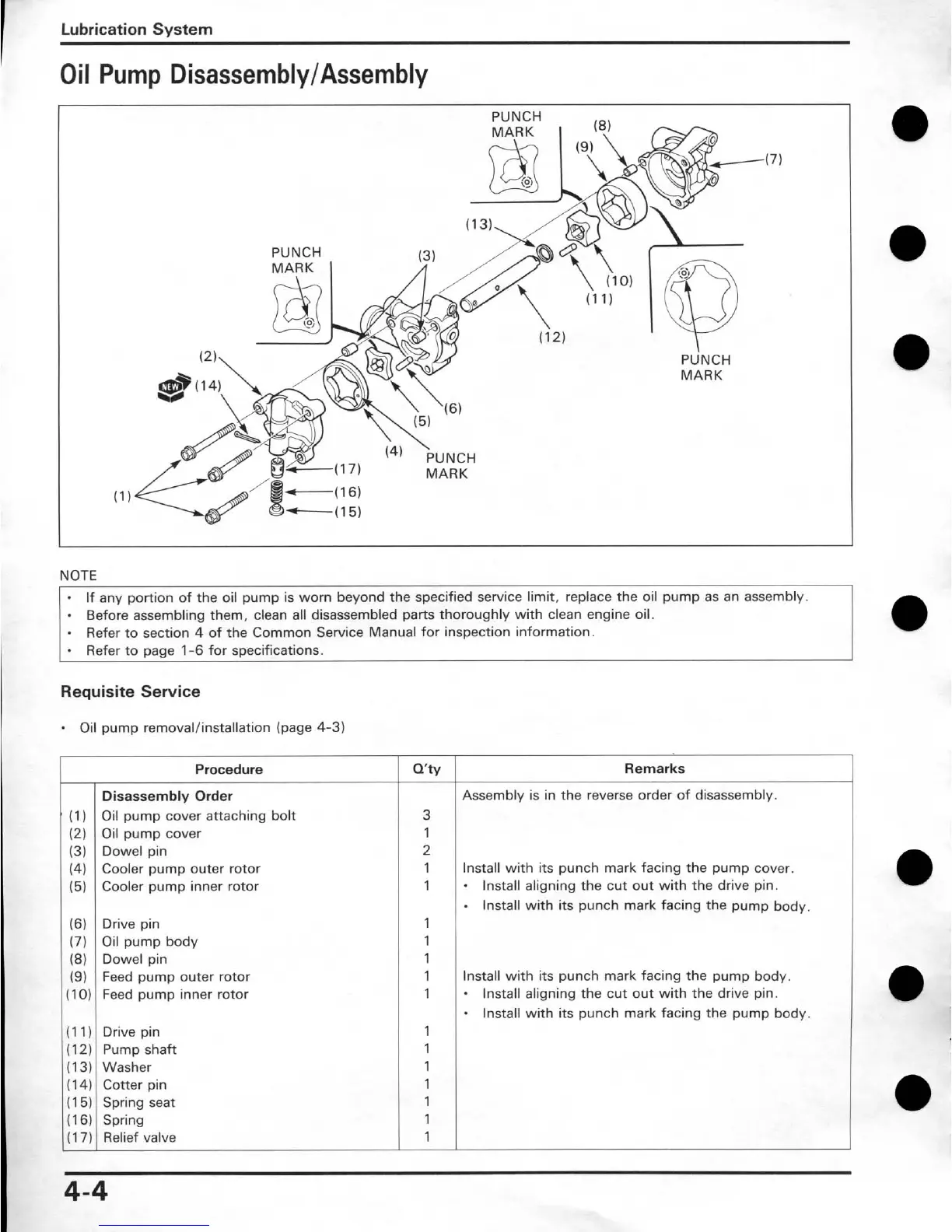

Oil Pump Disassembly/Assembly

PUNCH

PUNCH

MARK

NOTE

.

If any portion of the oil pump is worn beyond the specified service limit, replace the oil pump as an assembly.

-

Before assembling them, clean all disassembled parts thoroughly with clean engine oil.

Refer to section

4

of the Common Service Manual for inspection information.

-

Refer to oaoe

1-6

for soecifications.

Requisite Service

Oil pump removal/installation (page

4-3)

Procedure

(3)

(4)

(5)

(1

1

)

Drive pin

11

2)

PU~D shaft

1

i

Q'W

3

1

(1)

(2)

Dowel pin

Cooler pump outer rotor

Cooler pump inner rotor

(6)

(7)

(8)

(9)

(10)

Remarks

Assembly is in the reverse order of disassembly.

Disassembly Order

Oil pump cover attaching bolt

Oil pump cover

Drive pin

Oil pump body

Dowel pin

Feed pump outer rotor

Feed pump inner rotor

2

1

1

1

1

1

1

1

1

lnstall with its punch mark facing the pump cover.

.

lnstall aligning the cut out with the drive pin.

.

lnstall with its punch mark facing the pump body.

Install with its punch mark facing the pump body.

-

lnstall aligning the cut out with the drive pin.

lnstall with its punch mark facing the pump body.

(13)

(1

4)

(1 5)

(16)

(1

7)

washer

Cotter pin

Spring seat

Spring

Relief valve

1

1

1

1

1

Loading...

Loading...