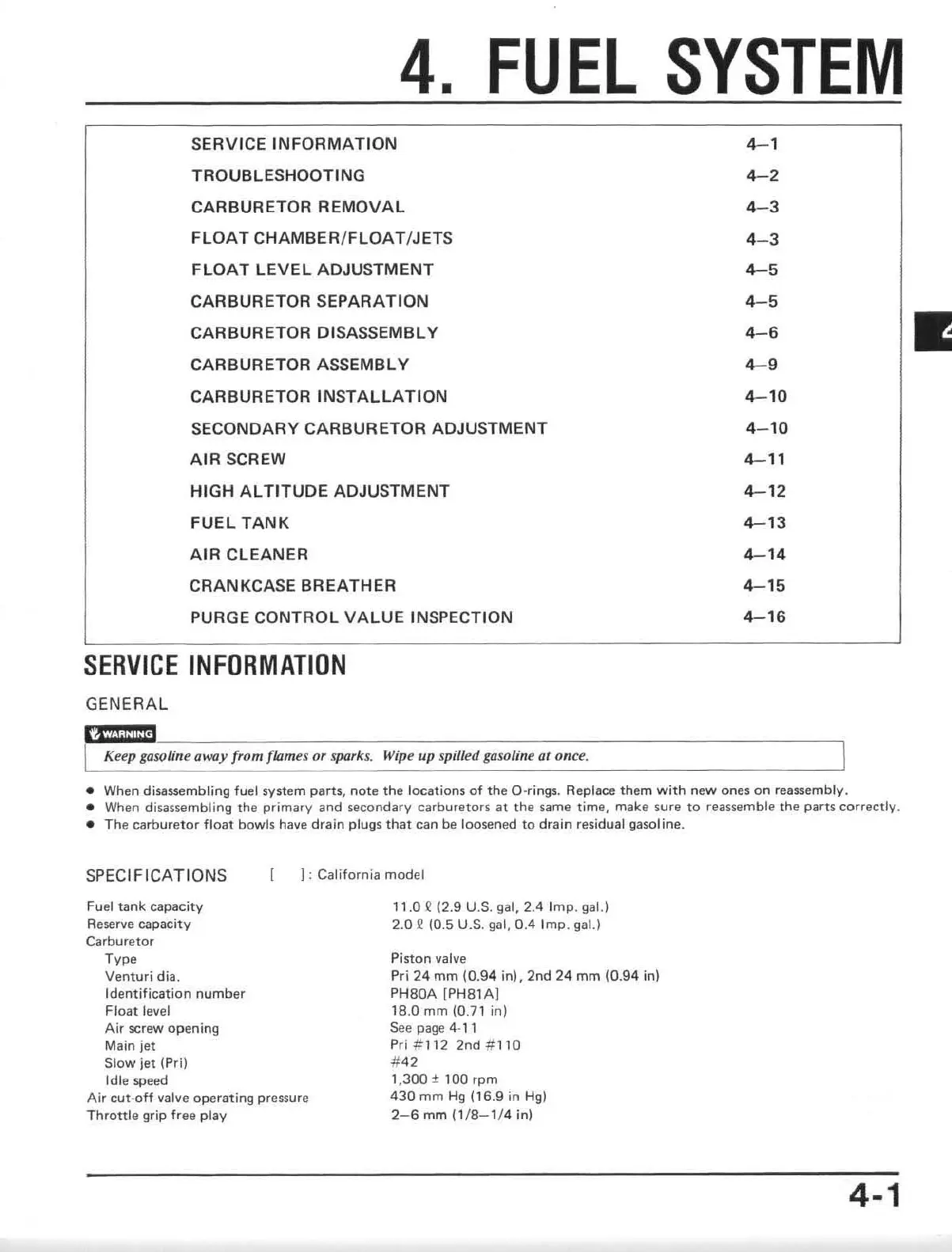

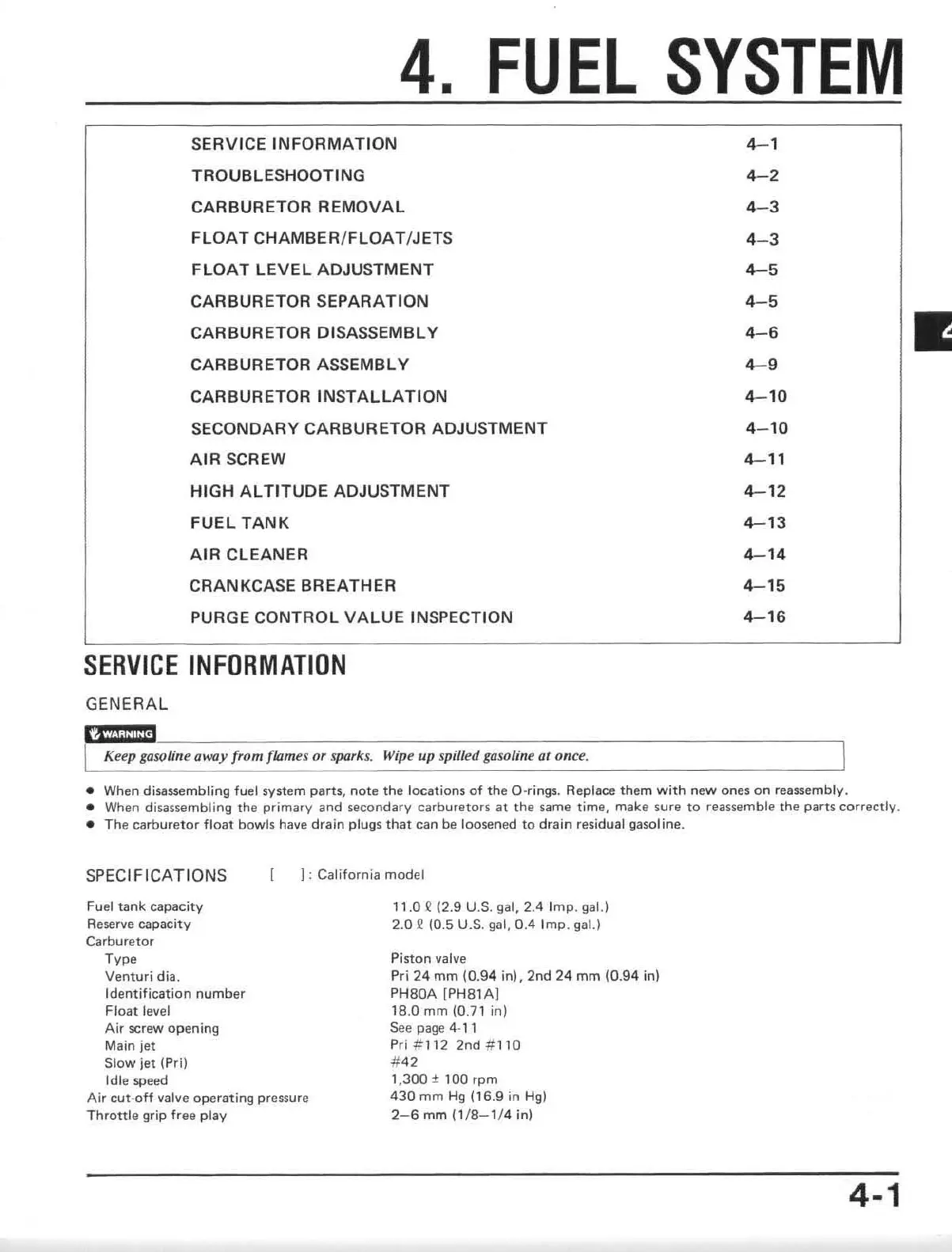

4.

FUEL

SYSTEM

SERVICE

INFORMATION

4-1

TROUBLESHOOTING

4-2

CARBURETOR

REMOVAL

4- 3

FLOAT

CHAMBER/

FLOAT

/J

ETS

4- 3

FLOAT

LEVEL

ADJUSTMENT

4-5

CARBURETOR SEPARATION

4-5

CARBURETOR DISASSEMBLY

4-6

CARBURETOR ASSEMBLY

4-9

CARBURETOR

INSTALLATION

4-10

SECONDARY CARBURETOR ADJUSTMENT 4- 10

AIR

SCREW

4-11

HIGH

ALTITUDE

ADJUSTMENT

4-12

FUEL

TANK

4-13

AIR

CLEANER

4-14

CRANKCASE BREATHER

4-15

PURGE CONTROL

VALUE

INSPECTION

4-16

SERVICE

INFORMATION

GENERAL

Keep gowline away from flames or sparks.

Wip

e up spilfell gasoline

or

once.

• When disassembling fuel system parts, n

ote

the

locations of the O-rings. Replace them

with

new

on

es

on

reassembly.

• When disassembling

the

primary

and

secondary

carburetors

at

th

e same time, make

sure

to

reassemble the

parts

correctly

,

• The carburet

or

fl

oat

bowls have

drain

plugs that can

be

loosened

to

drain

residual

gaso

l ine.

SPEC

IFICATIONS

I : California model

Fuel t

ank

capacity

Reserve capacity

Carburet

or

Type

Venturi dia.

Identification

nu

mber

Float

level

Air

screw opening

Main

jet

Sl

ow

jet

(Prj)

Idle speed

Air

cut-off

valve operating pressure

Throttle

grip free

play

11.0.Q

12.9 U.S. gal, 2.4 Imp, gaLl

2.0

~

(0.5 U.S. gal,

0.4

Imp

, gaL)

Piston

valve

Pr

j

24

mm

(0.9

4

in).

2nd

24

mm

(0.94 in)

PH

BOA

[P

HS1

A]

18.0

mm

(D.7l

in)

See

page 4-

11

Pri#1122nd#110

#42

1,300

± 1

00

rpm

430

mm

Hg

(16.9

in H

g)

2-6

mm

(1

/

8-1/

4 in)

4-1

•

Loading...

Loading...