RM7888A 7800 SERIES RELAY MODULE

31 32-00214—01

Equipment Recomended

• Voltmeter 1Mohm/volt minimum sensitivity set on the

0-300 Vac scale.

• Two jumper wires; 14 AWG wire, insulated, 12 inches

(304.8 mm) long, with insulated alligator clips at both

ends.

NOTE: An ammeter can replace one jumper wire so the

current draw of the loads (pilot valve, main valve

and ignition transformer) can be checked.

General Instructions

1. Perform all applicable tests listed in Static Checkout,

Table 10, in the order listed.

2. Make sure that all manual fuel shutoff valve(s) are

closed.

3. For each test, open the master switch and install the

jumper wire(s) between the subbase wiring termi-

nals listed in the Test Jumpers column.

4. Close the master switch before observing operation.

5. Read the voltage between the subbase wiring termi-

nals listed in the Voltmeter column.

6. If there is no voltage or the operation is abnormal,

check the circuits and external devices as described

in the last column.

7. Check all wiring for correct connections, tight termi-

nal screws, correct wire, and proper wiring tech-

niques. Replace all damaged or incorrectly sized

wires.

8. Replace faulty controllers, limits, interlocks, actua-

tors, valves, transformers, motors and other devices

as required.

9. Obtain normal operation for each required test

before continuing the checkout.

10. After completing each test, be sure to remove the

test jumper(s).

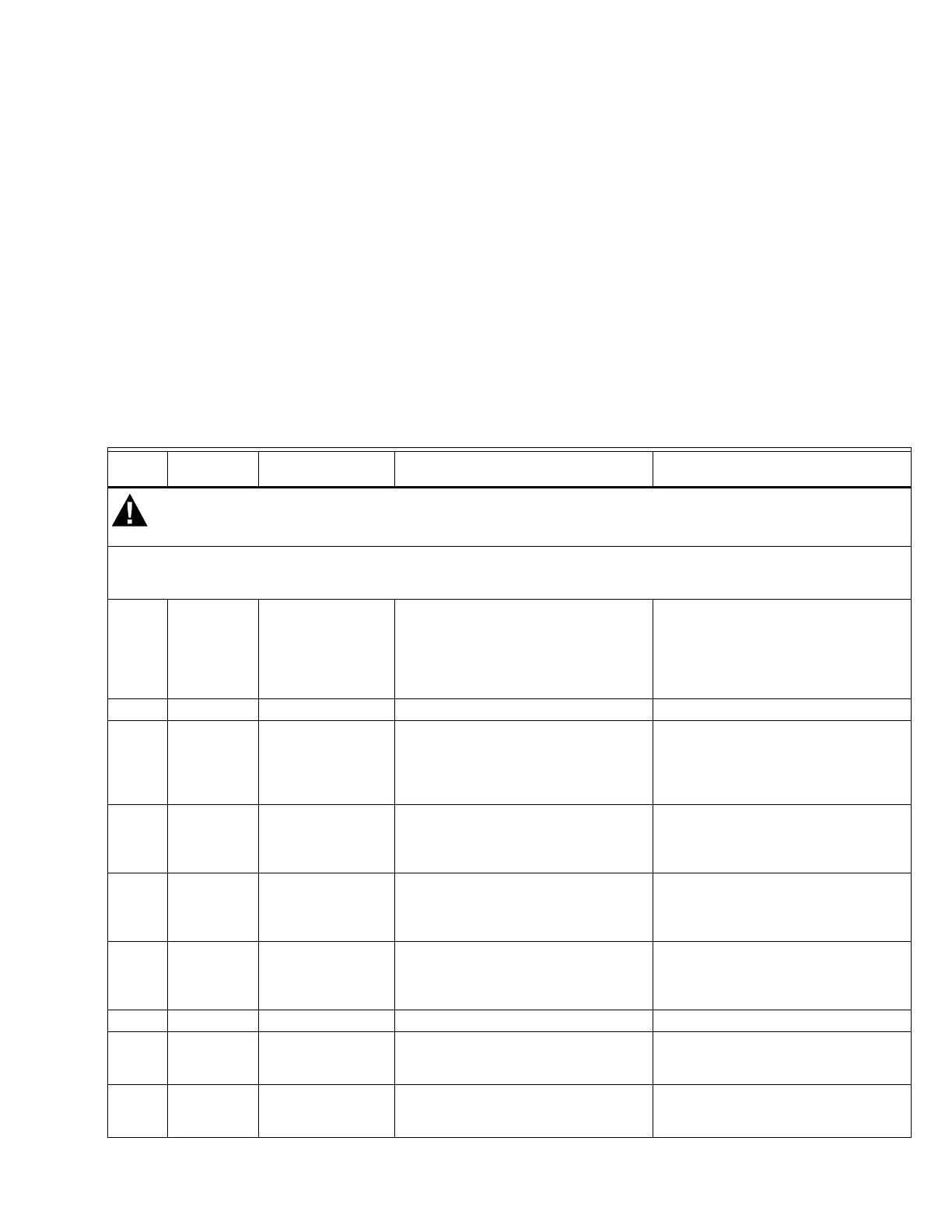

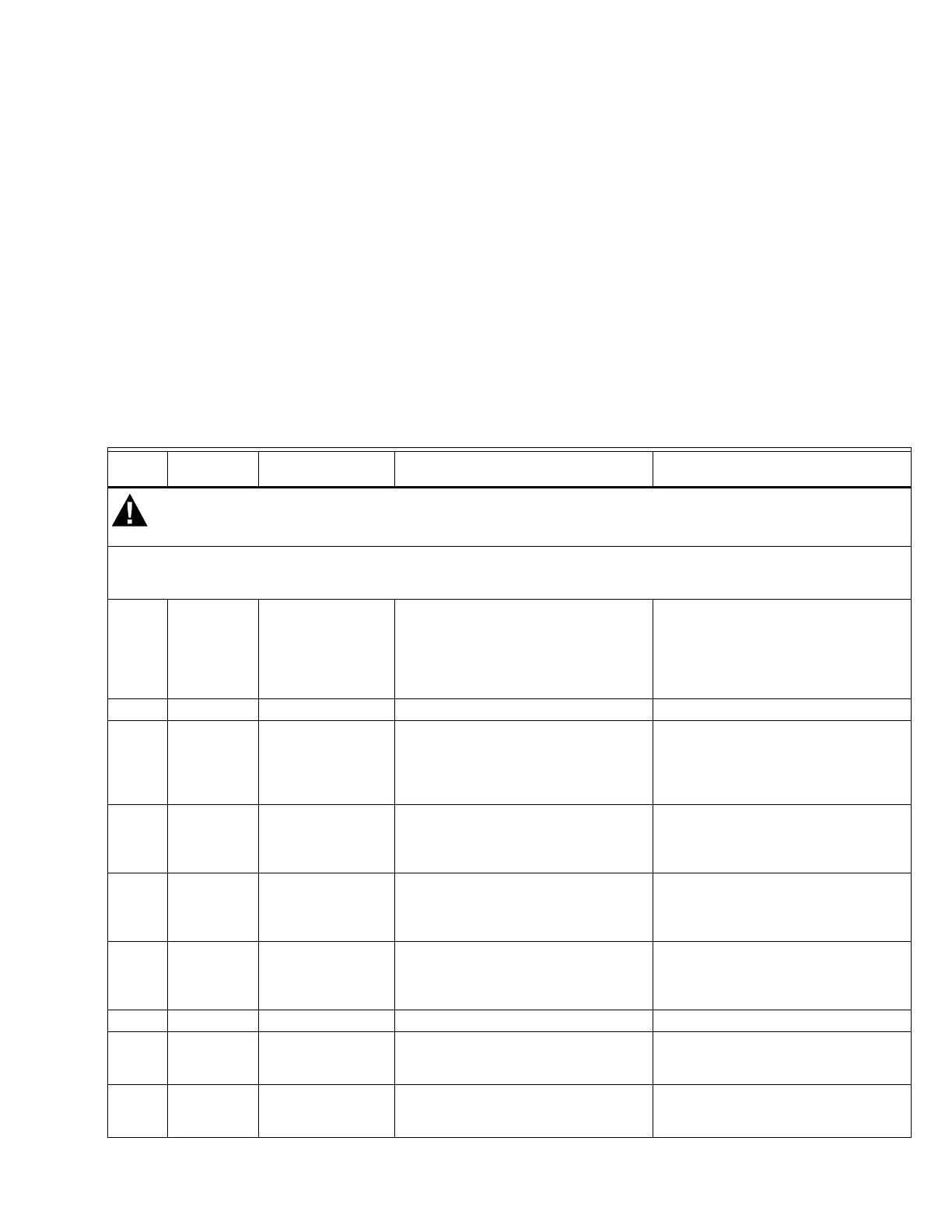

Table 10. Static Checkout.

Test

No.

Test

Jumpers Voltmeter Normal Operation

If Operation Is Abnormal, Check The

Items Listed Below

Make sure all manual fuel shutoff valves are closed.

IMPORTANT

Low fuel pressure limits, if used, could be open. Bypass them with jumpers for the remaining Static Tests (if

required).

1 None 4-L2 Line voltage at terminal 4. 1. Master switch.

2. Power connected to the master

switch.

3. Overload protection (fuse, circuit

breaker) has not opened the

power line.

2 None 7-L2 Line voltage at terminal 7. 1. Limits.

34-5 1. Air Valve starts. 1. Air Valve circuit.

a. Manual switch of Air Valve.

b. Air Valve power supply, over-

load protection, and starter.

c. Air Valve.

4 4-10 — Ignition spark 1. Watch for spark or listen for

buzz.

a. Ignition electrodes are clean.

b. Ignition transformer.

54-8 — 1. Automatic pilot valve opens.

NOTE: Refer to wiring diagram of

system being tested.

1. Listen for click or feel head of

valve for activation.

a. Actuator if used.

b. Pilot valve.

6 4-9 — Automatic main fuel valve(s) opens. 1. Listen for and observe operation

of the main fuel valve(s) and

actuator(s).

2. Valve(s) and actuator(s).

7 4 -3 — Alarm (if used) turns on. 1. Alarm

84-5 and

12-13

18-L2 Firing rate motor drives open; zero

volts at terminal 18 after motor starts

driving open.

1. Low Fire Start Switch.

2. Firing rate motor and trans-

former.

94-5 and

14-13

18-L2 Firing rate motor drives closed; line

voltage at terminal 18 after motor is in

Low Fire position.

1. Low Fire Start Switch.

2. Firing rate motor and trans-

former.

Loading...

Loading...