RM7888A 7800 SERIES RELAY MODULE

32-00214—01 32

CHECKOUT

Do not allow fuel to accumulate in the

combustion chamber. If fuel is allowed to enter

the chamber for longer than a few seconds

without igniting, an explosive mixture could

result. It is recommended that the trial for pilot

be limited to ten seconds, and the attempt to

light the main burner be limited to two seconds

from the time the fuel has reached the burner

nozzle. In any case, do not exceed the nominal

lightoff time specified by the equipment

manufacturer. Close the manual fuel shutoff

valve(s) if the flame is not burning at the end of

the specified time.

1. Use extreme care while testing the system. Line

voltage is present on most terminal connections

when power is on.

2. Open the master switch before removing or install-

ing the RM7888A.

3. Make sure all manual fuel shutoff valve(s) are

closed before starting the initial lightoff check and

the Pilot Turndown tests.

4. Do not put the system in service until you have

satisfactorily completed all applicable tests in this

section and any others required by the equipment

manufacturer.

If an RM7888A is replaced with a lower

functioning 7800 SERIES Relay Module, the

burner will not sequence unless wiring changes

are made.

IMPORTANT

1. If the system fails to perform properly, refer to the

Troubleshooting section and 7800 SERIES System

Annunciation and Troubleshooting, form 65-0229

2. Repeat ALL required Checkout tests after all

adjustments are made. ALL tests must be satisfied

with the flame detector(s) in its FINAL position.

Make sure all manual fuel shutoff valves are closed.

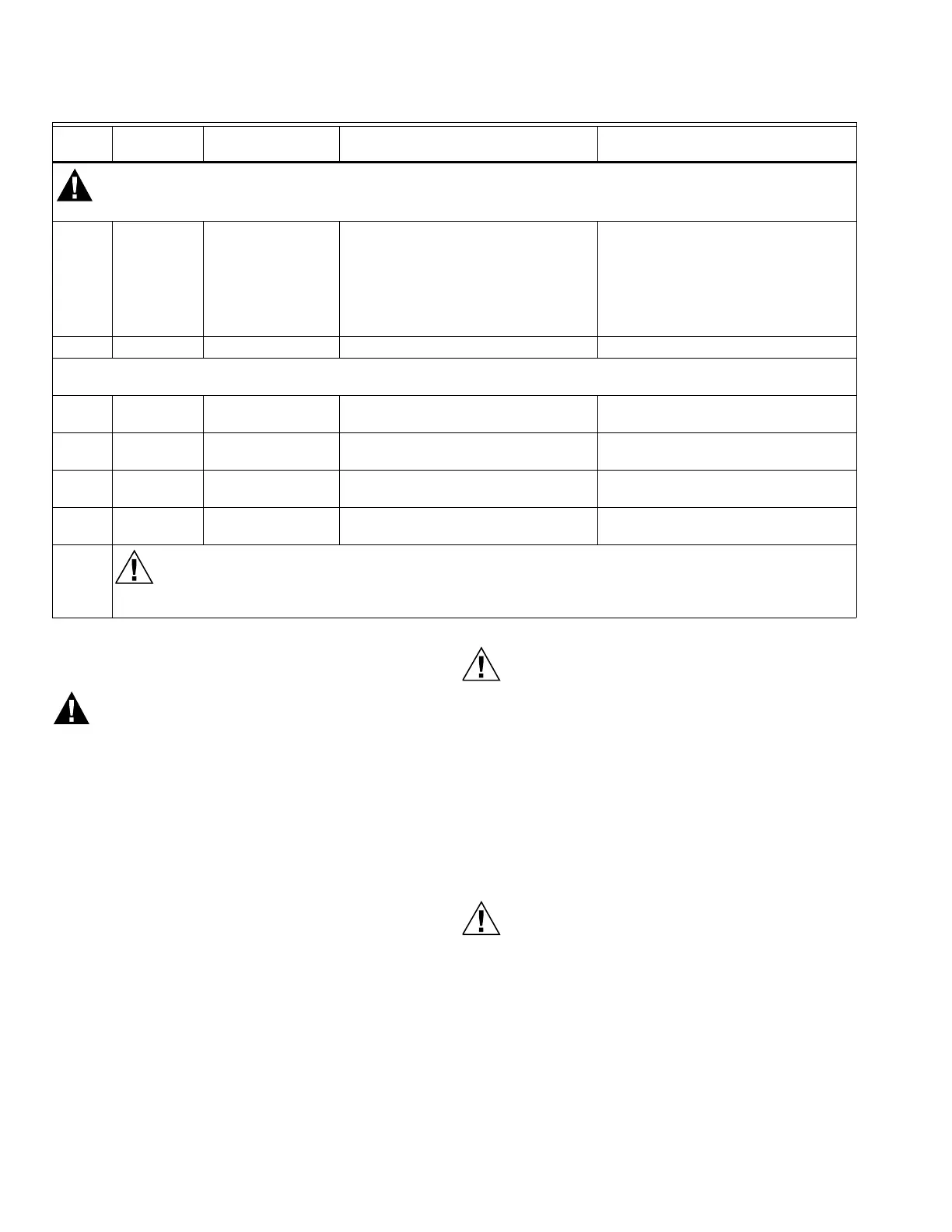

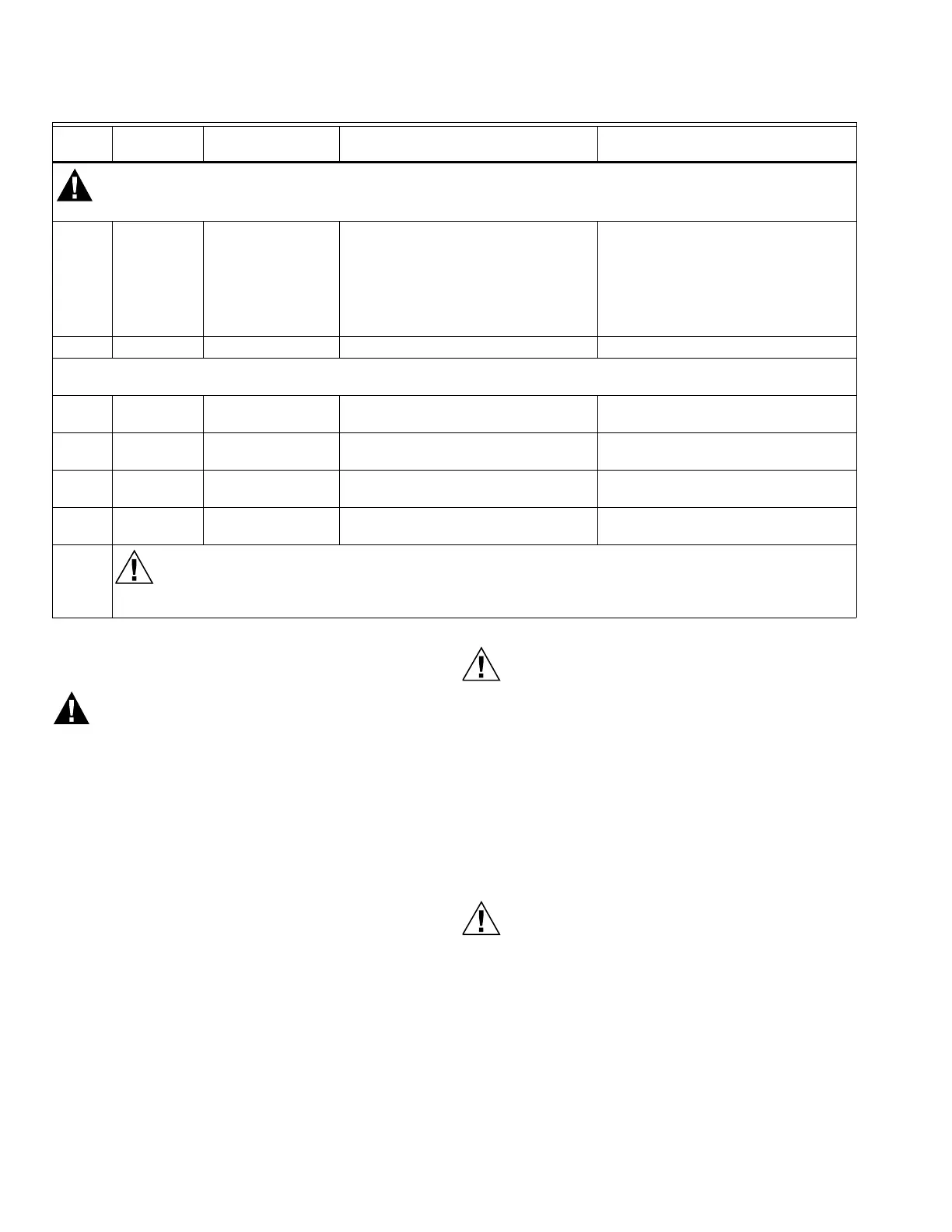

10 15-13 — 1. If modulation is used, raise set-

point of series 90 controller— fir-

ing rate motor should drive

toward open.

2. Lower set point of series 90 con-

troller—firing rate motor should

drive toward closed.

1. Series 90 Controller.

2. Firing rate motor and trans-

former.

11 4-21 — 1. Flame Proven circuit.

* Apply 120 Vac power to the special function inputs from the external controller/device one at a time (in sequence) and

perform tests 12 through 15.

12 — 1. 6-L2

2. 17, 19, 20-L2

1. Special Function 1 circuit.

13 — 1. 17-L2

2. 6, 19, 20-L2

1. Special Function 2 circuit.

14 — 1. 19-L2

2. 6, 17, 20-L2

1. Special Function 3 circuit.

15 — 1. 20-L2

1. 6, 17, 19-L2

1. Special Function 4 circuit.

Final

On completing these tests, open the master switch and remove all test jumpers from the subbase

terminals. Also remove bypass jumpers from the low fuel pressure limits (if used).

Table 10. Static Checkout. (Continued)

Test

No.

Test

Jumpers Voltmeter Normal Operation

If Operation Is Abnormal, Check The

Items Listed Below

Loading...

Loading...