Honeywell GmbH 7 MU1H-1002GE23 R0804

GB

7. Commissioning

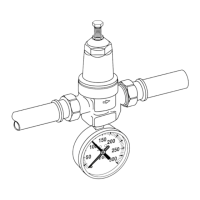

7.1 Setting outlet pressure (fig. 1)

1. Close shut off valves on inlet.

2. Release pressure on outlet side (e.g. through water

tap).

3. Loosen slotted screw.

Do not remove slotted screw.

4. Slacken tension in compression spring.

Turn adjuster knob to the left (-).

5. Close shut off valves on outlet.

6. Slowly open shut off valves on inlet..

7. Setting outlet pressure.

Turn adjuster knob until the adjustment scale

shows the desired value.

8. Retighten slotted screw.

9. Slowly open shut off valves on outlet.

10.Pressure reducing valve is now ready for use.

8. Maintenance

In accordance with DIN 1988, part 8, the following mea-

sures must be taken

:

8.1 Inspection

1. Close shut off valves on outlet.

2. Check outlet pressure with a manometer when no

flow is occurring.

3. Slowly open shut off valves on outlet.

8.2 Maintenance (fig. 2)

1. Close shut off valves on inlet.

2. Release pressure on outlet side (e.g. through water

tap).

3. Loosen slotted screw.

Do not remove slotted screw.

4. Slacken tension in compression spring.

Turn adjuster knob to the left (-).

5. Close shut off valves on outlet.

6. Unscrew spring hood.

Use double ring spanner ZR06K (☞ Accessories).

7. Remove slip ring.

8. Remove valve insert with a pair of pliers.

9. Unscrew filter bowl.

Use double ring spanner ZR06K (☞ Accessories).

10.Remove filter, clean and place back in position.

11. Lightly coat O-ring with silicone grease and place

onto filter bowl.

12.Check that sealing ring, edge of nozzle and slotted

ring are in good condition, and if necessary replace

the entire valve insert.

13.Reassemble in reverse order.

14.Press in diaphragm with finger before inserting slip

ring.

15.Setting outlet pressure (☞ chapter 7).

8.3 Setting adjustment scale (fig. 3)

If the adjustment knob is removed, this setting is lost.

A new setting can be achieved using a manometer (☞

Accessories).

1. Close shut off valves on inlet.

2. Release pressure on outlet side (e.g. through water

tap).

3. Loosen slotted screw.

4. Close shut off valves on outlet.

5. Fit manometer.

6. Slowly open shut off valves on inlet.

7. Set desired outlet pressure (f.e. 4 bar).

8. Align scale in middle of viewing window.

9. Retighten slotted screw.

10.Slowly open shut off valves on outlet.

11. Pressure reducing valve is now ready for use.

i

• Admission pressure should be approx. 1 bar

higher than the outlet pressure that has

been set

i

• We recommend a planned maintenance

contract with an installation company

i

• Frequency: once annually

• To be carried out by an installation company

• To be carried out by the operator

•CAUTION!

If pressure is slowly rises, then proceed as

described under ☞ Maintenance!

i

• Frequency: every 1-3 years (depending on

local operating conditions)

• To be carried out by an installation company

OBJ_BUCH-10-001.book Seite 7 Donnerstag, 11. November 2004 4:43 16

Loading...

Loading...