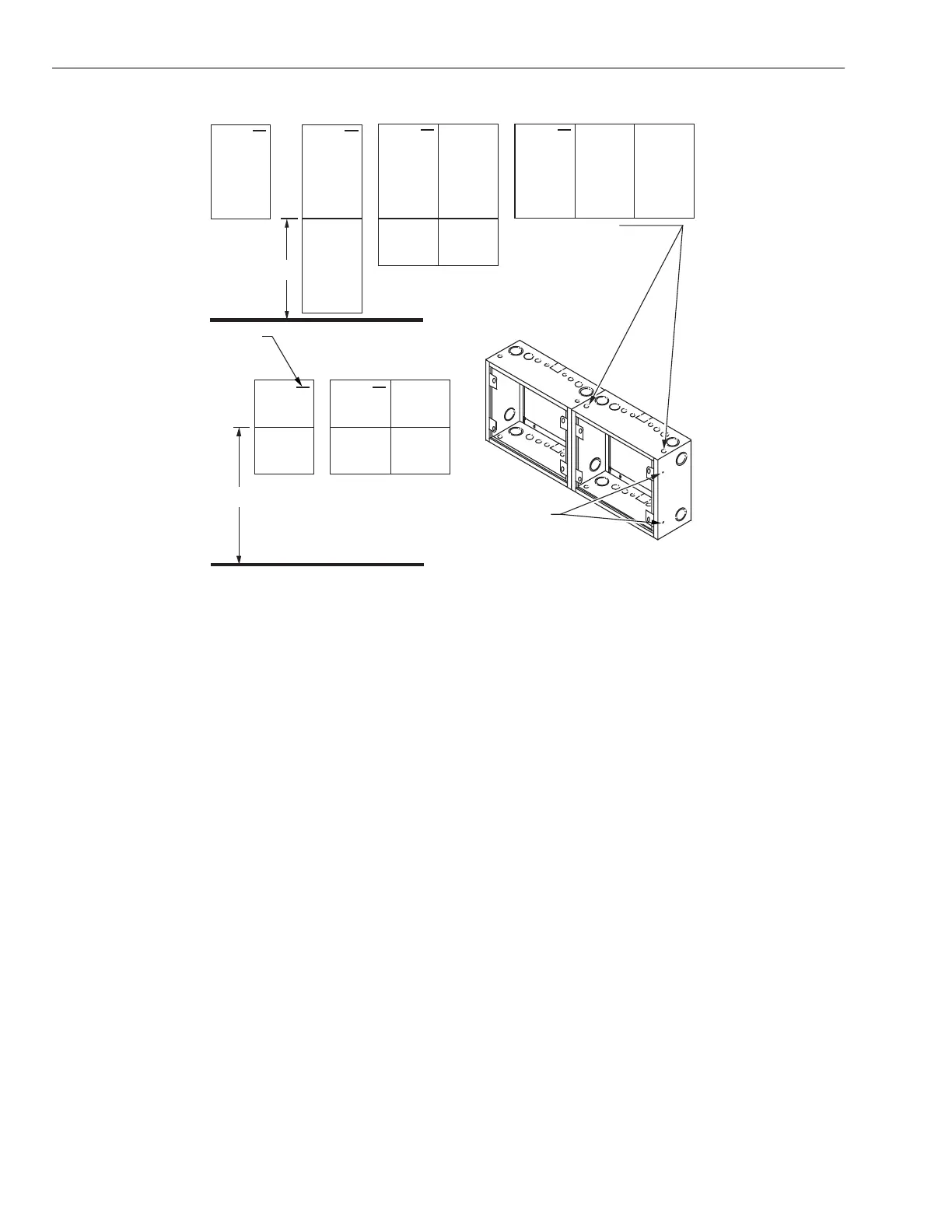

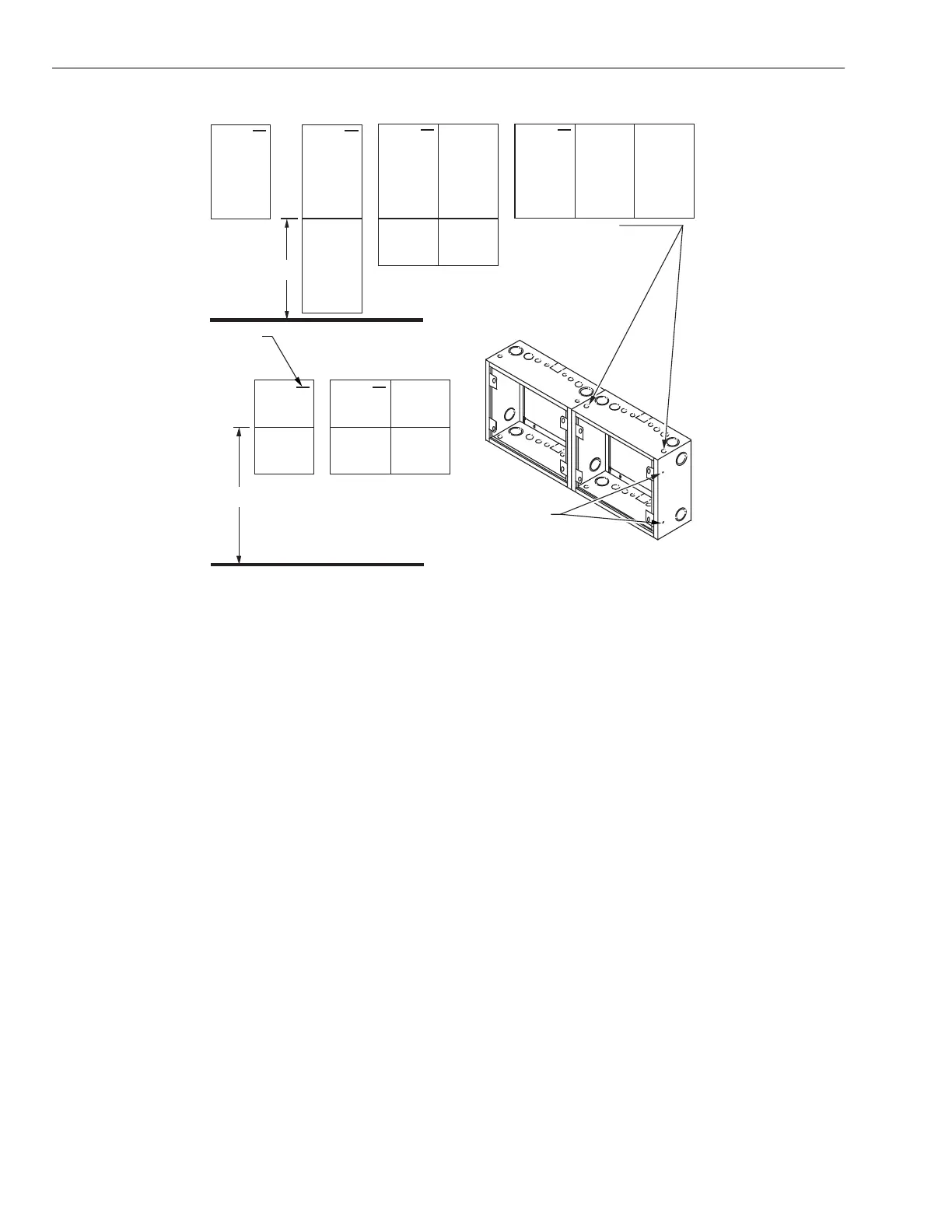

EXCEL 5000™ SYSTEM STYLED CABINET RINGS AND SUBPANELS

40 (1016)

NAMEPLATE

54 (1372)

USE 1/4-20 x 3/4-IN.

BOLTS, NUTS, AND

5/16 (8) KNOCKOUTS

USE 1/4-20 x 3/4-IN.

BOLTS, 1-1/4-IN.

DIAMETER WASHERS

WITH 1/4-IN. HOLE

(CCT2369 OR EQUAL),

NUTS, AND 1/2 (13)

KNOCKOUTS TO

FASTEN CABINETS

VERTICALLY.

(OBTAIN BOLTS,

WASHERS, AND

NUTS LOCALLY.)

TO FASTEN CABINETS

HORIZONTALLY.

(OBTAIN BOLTS,

WASHERS, AND

NUTS LOCALLY.)

C7084

Fig. 6. Surface, semi-flush Ring arrangements (dimensions in in. (mm)).

General Mounting

— The cabinet/enclosure must be attached to a solid surface

masonr

or concrete slab

or to the wall framin

members.

— The cabinet attachment must be securel

anchored to the

wall and be desi

ned to hold at least four times the wei

ht

of a full-loaded cabinet.

— Enclosure mountin

must be in accordance with all

applicable codes.

— The maximum wei

ht of the enclosure and its contents

must not exceed 50 lbs.

— Unless otherwise noted, the top of the cabinet is positioned

at the top of the drawin

s in this document.

— The cabinet must be mounted in the position shown.

Drywall

To mount:

1.

Use at least four mountin

points and all of the enclo-

sure mountin

holes must be ali

ned over the center of

the studs.

2.

Use a minimum 1/4 in.

6 mm

x 2-1/2 in.

64 mm

la

screw with flat washer and lock washer into center of

stud.

Concrete

To mount:

1.

Establish a minimum of four mountin

points in the con-

crete and ali

n with the cabinet mountin

holes at the

four corners of the enclosure.

2.

Install carbon steel wed

e anchors with 1/4 in. diameter

x 2-1/4 in. lon

57 mm

minimum screw

ITW Ramset/

Red Head Trubolt or e

ual

, per the manufacturer’s

instructions, to a depth of at least 1-15/16 in.

49 mm

.

3.

Bolt the four corners of the enclosure to the wall usin

this hardware and a 1/4 in.

6 mm

steel split lock

washer.

NOTE: Mountin

hardware must meet U.S. Government

G.S.A. specification FF-S-325 Group II, T

pe 4,

Class 1.

Masonry

To mount:

1.

Establish a minimum of four mountin

points in the

masonr

and ali

n with the cabinet mountin

holes at

the four corners of the enclosure.

2.

Install carbon steel sleeve anchors desi

ned to accept

1/4 in. diameter

6 mm

x 1-1/2 in. lon

38 mm

screws

ITW Rasmet/Red Head D

nablot or e

ual

, per the

manufacturer’s instructions, to a depth of at least 1-1/4

in.

32 mm

3.

Bolt the four corners of the enclosure to the wall usin

this hardware and a 1/4 in.

6 mm

steel split lock

washer.

95-7487—1 4

Loading...

Loading...