EXCEL 5000™ SYSTEM STYLED CABINET RINGS AND SUBPANELS

NOTE: Mountin

hardware must meet U.S. Government

G.S.A. specification FF-S-325 Group II, T

pe 3,

Class 3.

Other mountin

methods are allowed to meet the construction

methods used in the field, provided the

are at least as stron

as the methods detailed above.

Alternative mountin

methods of e

ual or

reater stren

th are

allowed provided the

also meet or exceed all local code

re

uirements.

Surface Mounting

1.

Use the Rin

as a template and mark and drill four

mountin

holes

see Fi

. 3

.

2.

Use the proper mountin

hardware for wall construction

and secure Rin

to mountin

surface with four 1/4 in.

diameter bolts or screws

see Fi

. 3

.

3.

Install a dirt barrier

scrap cardboard or plastic sheet

on

the front of the Rin

to block construction debris, if

needed.

4.

Continue with the Subpanel Mountin

section.

Semiflush Mounting

1.

Refer to Fi

. 3 for rou

h-in hole dimensions.

NOTE: Rin

mountin

depth in wall

see Fi

. 7

depends on

wall construction and

ob specifications. However,

the Rin

must extend a minimum of 3/4 in.

19 mm

from wall.

2.

Use the proper mountin

hardware for wall construction

and secure Rin

to mountin

surface with four 1/4 in.

diameter bolts or screws

see Fi

. 3

.

3.

Install a dirt barrier scrap cardboard or plastic sheet

on

the front of the Rin

to block construction debris, if

needed.

4.

Continue with the Subpanel Mountin

section.

Subpanel Mounting

After construction is complete, remove the dirt barrier and an

debris on front of Rin

and install Subpanel

see Fi

. 8

.

Tamper Switch (Optional)

1.

Remove the two screws and lock washers from the

Tamper Switch.

2.

Assemble a lock washer on each screw.

3.

Install the Tamper Switch

see Fi

. 9

NOTE: For ease of installation, install the top screw and lock

washer first.

4.

Ti

hten both screws and check for proper switch opera-

tion

plun

er moves freel

.

5.

Loosen lock-nut and ad

ust plun

er screw for proper

Tamper Switch operation.

6.

Hold plun

er screw and ti

hten lock-nut.

7.

Wire the Tamper Switch accordin

to

ob drawin

s.

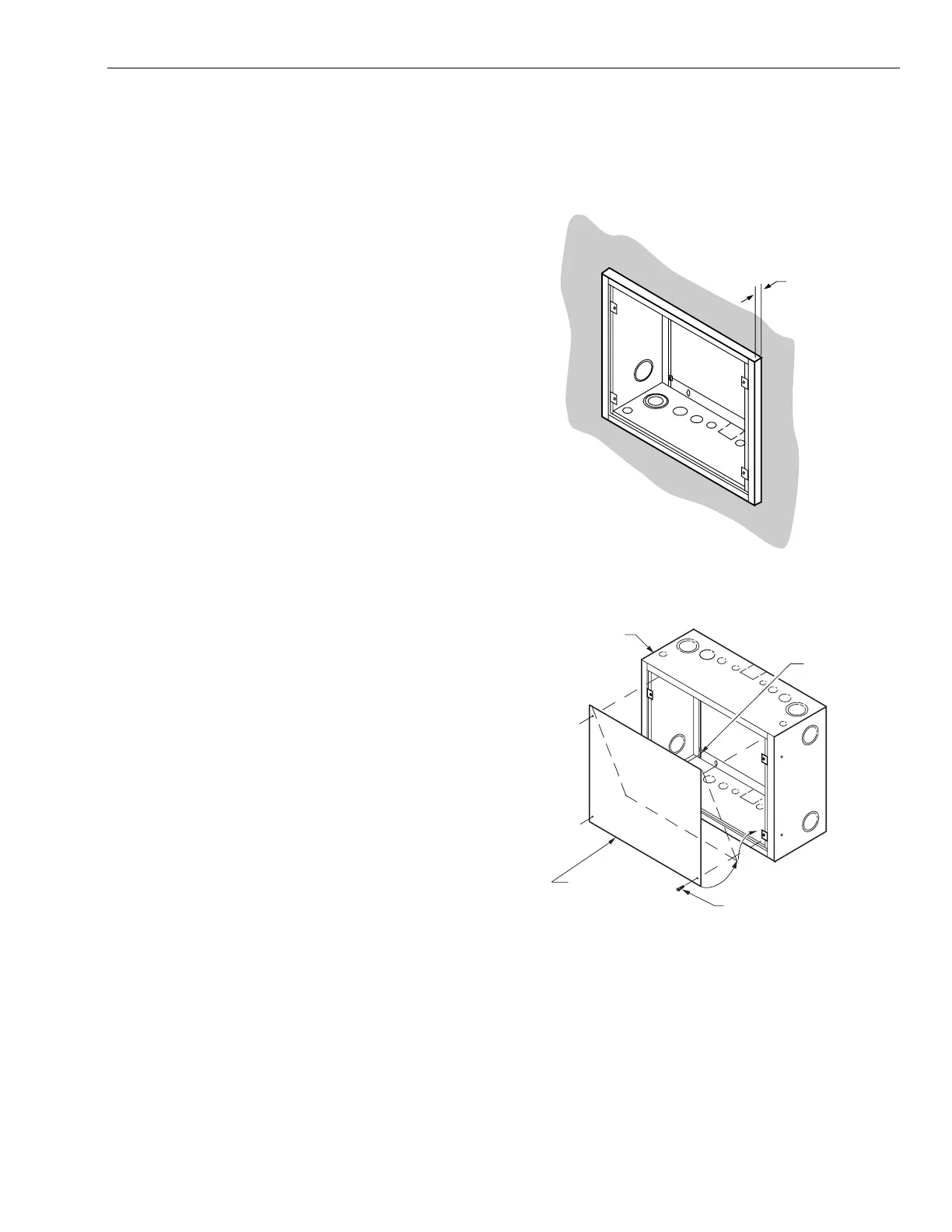

WALL

RING EXTENDS

A MINIMUM OF

3/4 IN. (19 MM)

FROM WALL

C7088

Fig. 7. Semiflush mounted Ring (small sized Ring shown).

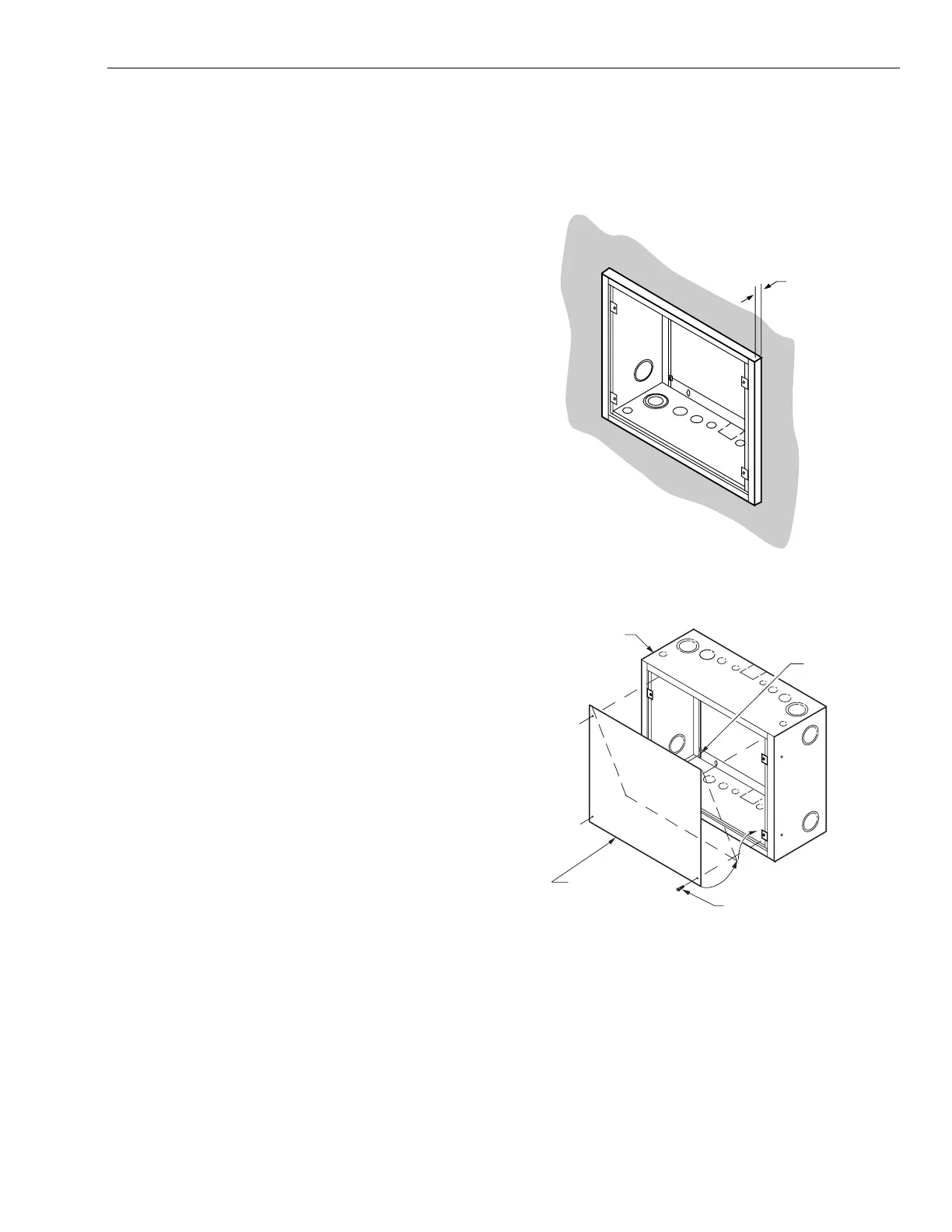

FASTENERS

PROVIDED

WITH RING

RING

INSERT BOTTOM OF

SUBPANEL FIRST

NO. 10 x 3/8-IN.

SHEET METAL SCREW

(OBTAIN LOCALLY)

SMALL-SIZED SUBPANEL (4)

FULL-SIZED SUBPANEL (6)

C7085

Fig. 8. Subpanel installation (small-sized Ring shown).

5 95-7487—1

Loading...

Loading...