Do you have a question about the Honeywell Krom Schroeder BCU 480 and is the answer not in the manual?

| Brand | Honeywell |

|---|---|

| Model | Krom Schroeder BCU 480 |

| Category | Control Unit |

| Language | English |

Describes various burner configurations and their application with the BCU 480.

Provides detailed wiring diagrams for different BCU 480 models and configurations.

Outlines the step-by-step operational logic and sequence for burner startup and operation.

Details the settings and behavior related to flame detection and monitoring using various sensors.

Details critical timing parameters and sequences during the burner start-up phase.

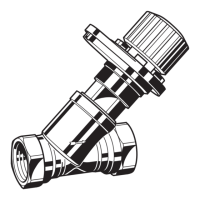

Explains how the air valve functions and its control parameters for different operating modes.

Explains the meaning of each code in the BCU 480 part number for configuration.

Details recommendations for selecting appropriate cables for signal, control, and power connections.

Covers the specifics of integrating the BCU 480 with PROFIBUS DP networks, including wiring and communication.

Describes flame detection using ionization sensors, including operating principles and safety levels.

Explains indirect flame control using temperature monitoring in high-temperature applications.

Information on the BCSoft software and associated adapters for configuration and data access.

Lists safety-related data including SIL/PL levels and diagnostic coverage.

Describes the function of the various controls and indicators on the BCU 480 unit.

Defines the safety time on start-up (tsa) for pilot gas valve V1 operation.

Defines the safety time (tsB) for valve operation during normal running.

Loading...

Loading...