VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

38-00032—01 18

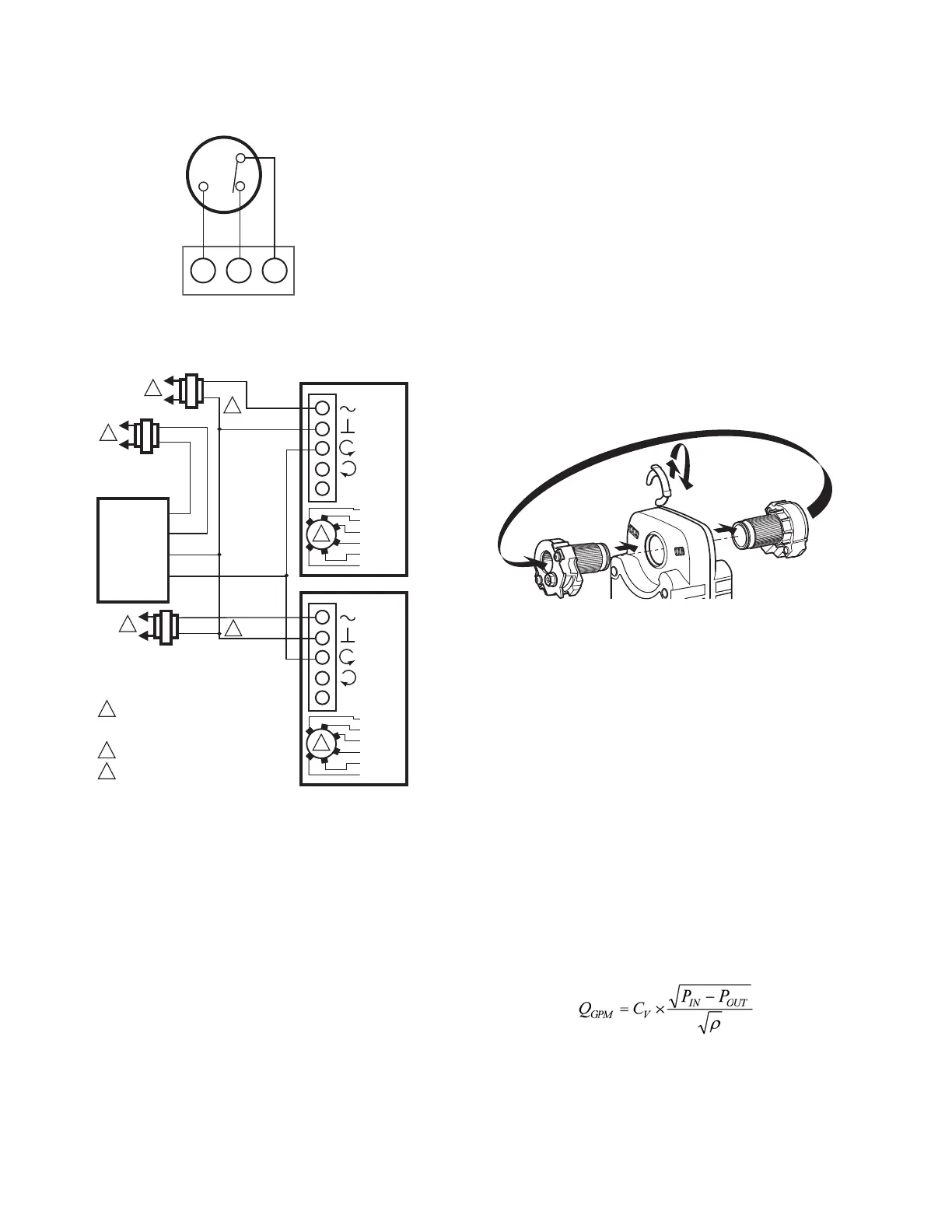

Fig. 26. Wiring for model with aux./end switches.

Fig. 27. MS7505 with Proportioning controllers

operating multiple actuators (Modulating mode setting).

NOTE: All identified parts except for the valve body and

aluminum valve stem coupler are included in

Replacement Kit (part no. 5112-11).

OPERATION AND CHECKOUT

Once both the mechanical and electrical installations are

complete:

1. Cycle the actuator to verify that the direction of rota-

tion suits the control sequence.

2. If the rotation direction is incorrect:

a. For 2-position spring return actuators: Remove,

flip over, and replace actuator on the bracket.

b. For floating control actuators: Reverse two control

signal wires (CW/CCW), or change position of

selector switch.

c. For analog control actuators either:

(3) Change setting of reverse/direct-acting

switch, or

(4) Remount actuator on the bracket.

3. If the control scheme requires fail-safe operation,

ensure that, upon removal of power, the fail position

coincides with the control sequence.

4. Spring return actuators are factory-configured for

normally-closed, fail-safe operation on power loss. To

change this action to normally-open, remove and

reinstall the actuator in the opposite orientation as

follows:

a. Loosen the shaft coupling bolt using a 10 mm

wrench.

b. Loosen all other mounting bolts connecting the

actuator to the mounting bracket, and set aside.

c. Remove the actuator from the valve shaft.

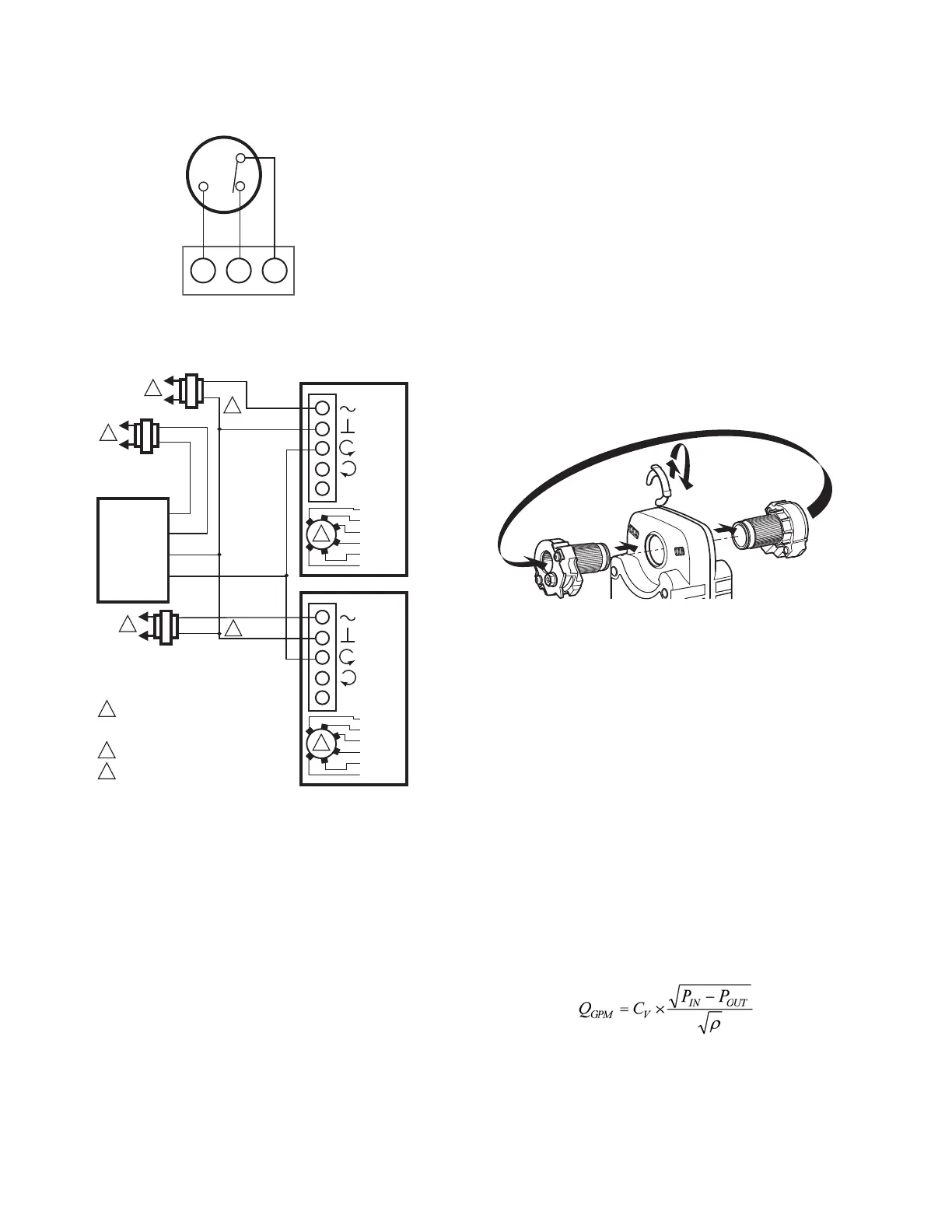

d. Move the Self-Centering Shaft Adaptor to the

opposite side of the actuator, as displayed in

Fig. 28.

Fig. 28. Change actuator to normally open.

(1) Remove the retainer clip from the

Self-Centering Shaft Adapter and set it aside

for later use.

(2) Remove SCSA from actuator.

(3) Reinstall SCSA on the opposite side of the

actuator, aligning it based on the stroke

labeling.

(4) Replace the retainer clip on the shaft coupling

using the groove of the coupling.

e. Reconnect the actuator to the valve mounting

bracket by replacing the screws previously

removed (step b).

f. Tighten the shaft coupling bolt using a 10 mm

wrench or socket.

Operation

The differential pressure regulator maintains constant

pressure drop across the valve seat through a wide range of

head pressures. At a given ball position, flow through the

valve will be constant as defined by the formula:

where ρ is the density of the glycol mix.

P

IN

changes constantly in a multi-zone system as other

valves open and close, changing system flow and head

pressure according to the characteristics of the supply

pump curve. Reaction of the mechanical pressure

regulator is instantaneous, eliminating changes in room

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

M34978

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

ACTUATOR

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

24 VAC

1

24 VAC

1

2

24 VAC

1

HOT

COM

–

+

M27714

Loading...

Loading...