32-00156-03 10

RM7895A,B,C,D/EC7895A,C; RM7896A,C,D7800 SERIES Relay Modules

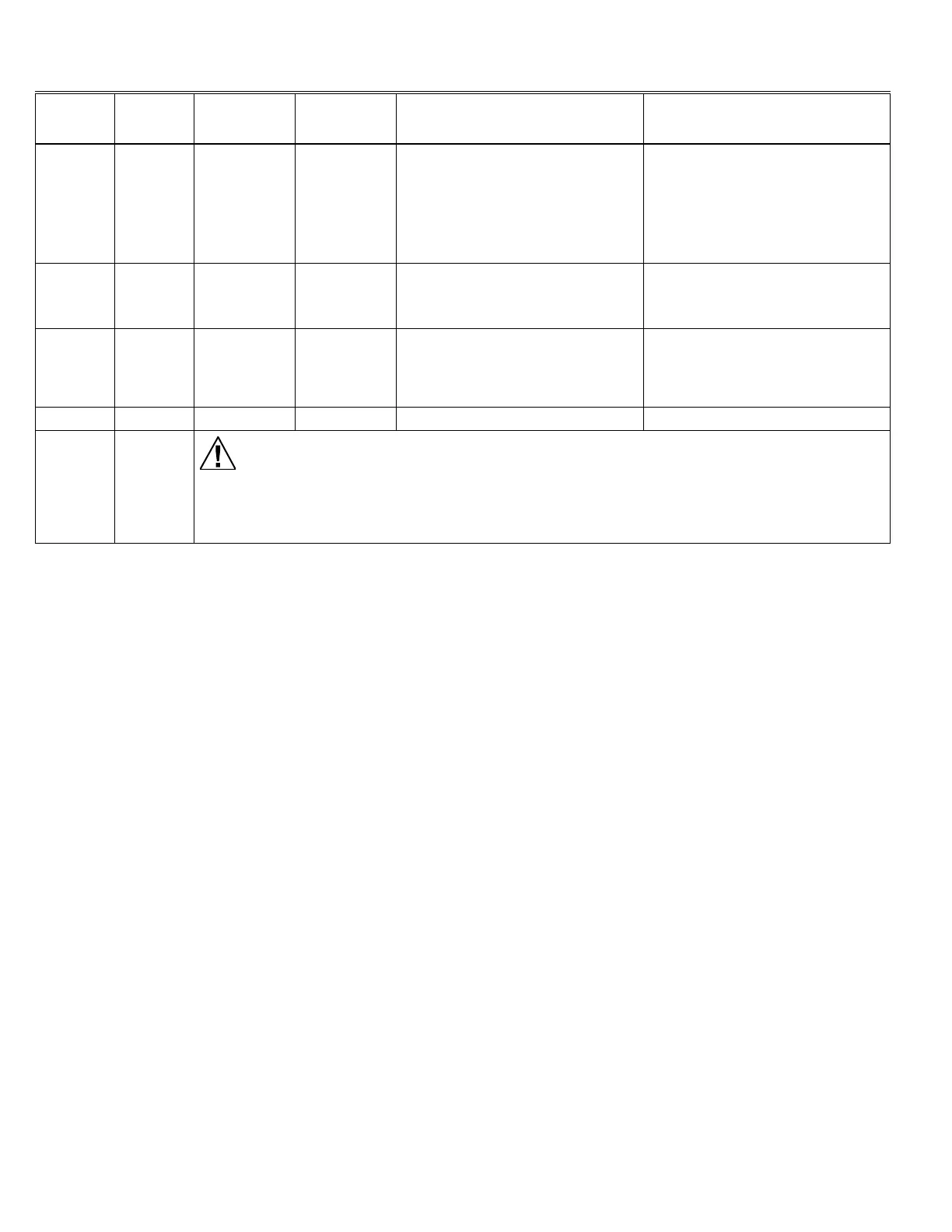

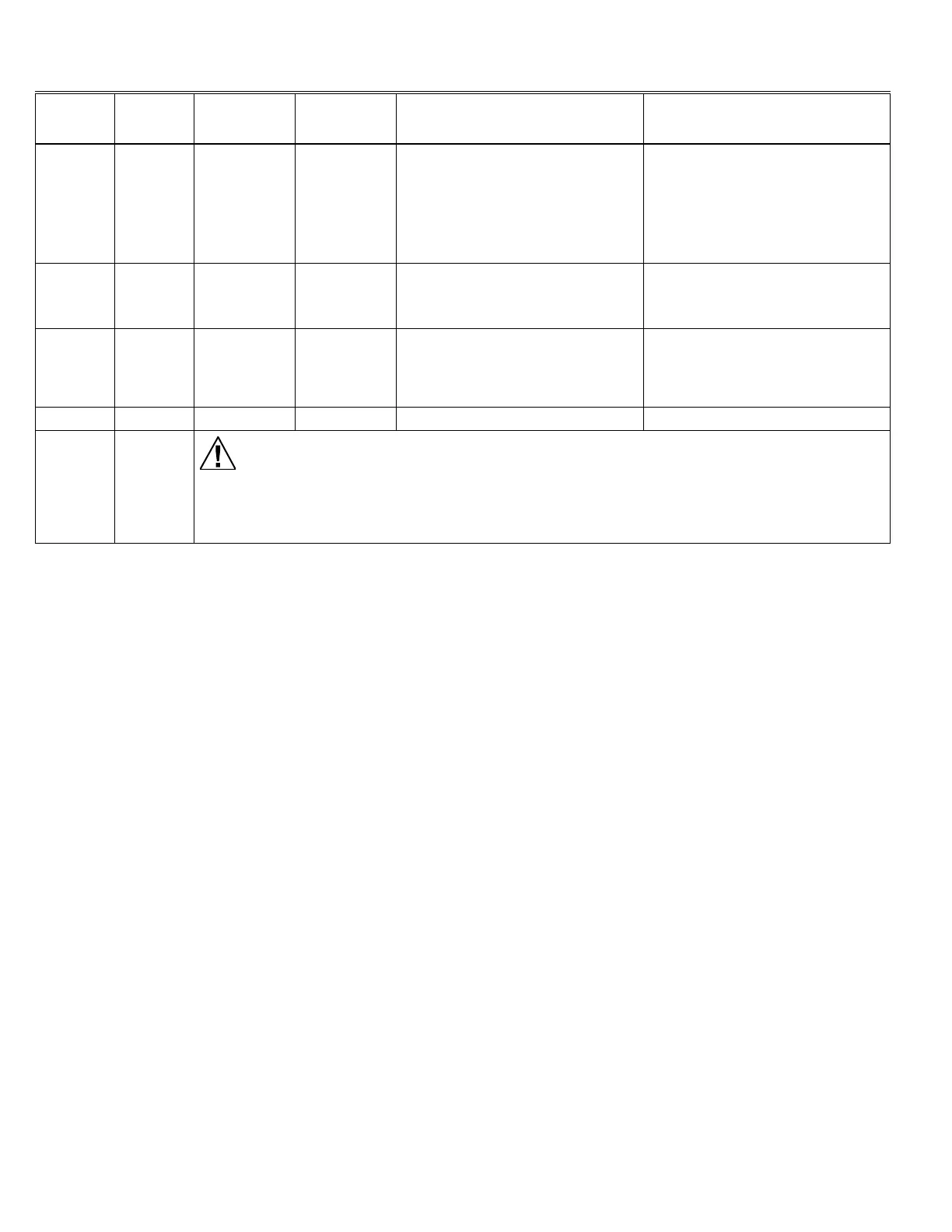

Table 6: Static Checkout. (Continued)

Test

Number

Relay

Module

Model

Test

Jumpers

Voltmeter Normal Operation If Operation is Abnormal,

Check Items Listed Below

5 All 5-8 – 1. Ignition spark (if ignition

transformer is connected to

terminal 8).

2. Automatic pilot valve opens (if

connected to terminal 8).

NOTE: Refer to wiring diagram of

system being tested.

1. Watch for spark or listen for

buzz.

2. Listen for click or feel head of

valve for activation.

a. Actuator if used.

b. Pilot valve.

6 All 5-9 – Automatic fuel valve(s) open(s). If

using direct spark ignition, check

first stage fuel valve(s) instead of

pilot valve.

Same as test 5. If using direct

spark ignition, check first stage

fuel valve(s) instead of pilot valve.

7

EC7895C;

RM7895C

,D;

RM7896C

,D

5-21 – Automatic second stage main fuel

valve(s) open(s).

1. Listen for and observe operation

of second stage main fuel valve(s)

and actuator(s).

2. Valve(s) and actuator(s).

8 All 5-3 – Alarm (if used) turns on. 1. Alarm.

Final All

CAUTION

Equipment Damage Hazard.

Can cause equipment damage.

After completing these tests, open master switch and remove all test jumpers from subbase

terminals. Also remove bypass jumpers, if used, from low fuel pressure limits.

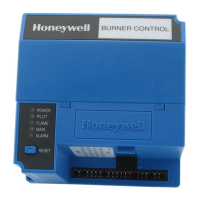

Mounting

RM7895A,B,C,D/EC7895A,C;

RM7896A,B,C,D Relay Module

1. Mount the RM7895A,B,C,D/EC7895A,C;

RM7896A,B,C,D vertically on the Q7800 Subbase

or mount horizontally with the knife blade terminals

pointing down. When mounted on the Q7800A, the

RM7895A,B,C,D/EC7895A,C; RM7896A,B,C,D must be in

an electrical enclosure.

2. When mounting in an electrical enclosure, provide ade-

quate clearance for servicing, installation and removal of

the RM7895A,B,C,D/EC7895A,C; RM7896A,B,C,D, KDM,

flame amplifier, flame amplifier signal voltage probes,

electrical signal voltage probes and electrical connections.

a. Allow an additional two inches (51 mm) below the

RM7895A,B,C,D/EC7895A,C; RM7896A,B,C,D for the

flame amplifier mounting.

b. Allow an optional three-inch (76 mm) minimum on both

sides of the

RM7895A,B,C,D/EC7895A,C; RM7896A,B,C,D for

electrical signal voltage probes.

3. Make sure no subbase wiring is projecting beyond the

terminal blocks. Tuck in wiring against the back of the sub-

base so it does not interfere with the knife blade terminals

or bifurcated contacts.

IMPORTANT

The RM7895A,B,C,D/EC7895A,C; RM7896A,B,C,D must be

installed with a plug-in motion rather than a hinge action.

4. Mount the RM7895A,B,C,D/EC7895A,C; RM7896A,B,C,D

by aligning the four L-shaped corner guides and knife

blade terminals with the bifurcated contacts on the wiring

subbase and securely tightening the two screws without

deforming the plastic.

Mounting Other System Components (Fig. 4)

Refer to the applicable specifications for mounting other sys-

tem components.

PRINCIPAL TECHNICAL FEATURES

The RM7895 and EC7895 Series provide all customary flame

safeguard functions as well as significant advancements in

safety, annunciation, and system diagnostics.

Safety Shutdown (Lockout) Occurs if:

1. INITIATE PERIOD

a. Purge card is not installed or removed.

b. Purge card is bad.

c. Configuration jumpers have been changed (after 200

hours)—Fault Code 110.

d. AC line power errors occurred, see Operation.

e. Four minute INITIATE period has been exceeded.

Loading...

Loading...