7 32-00156-03

RM7895A,B,C,D/EC7895A,C; RM7896A,C,D7800 SERIES Relay Modules

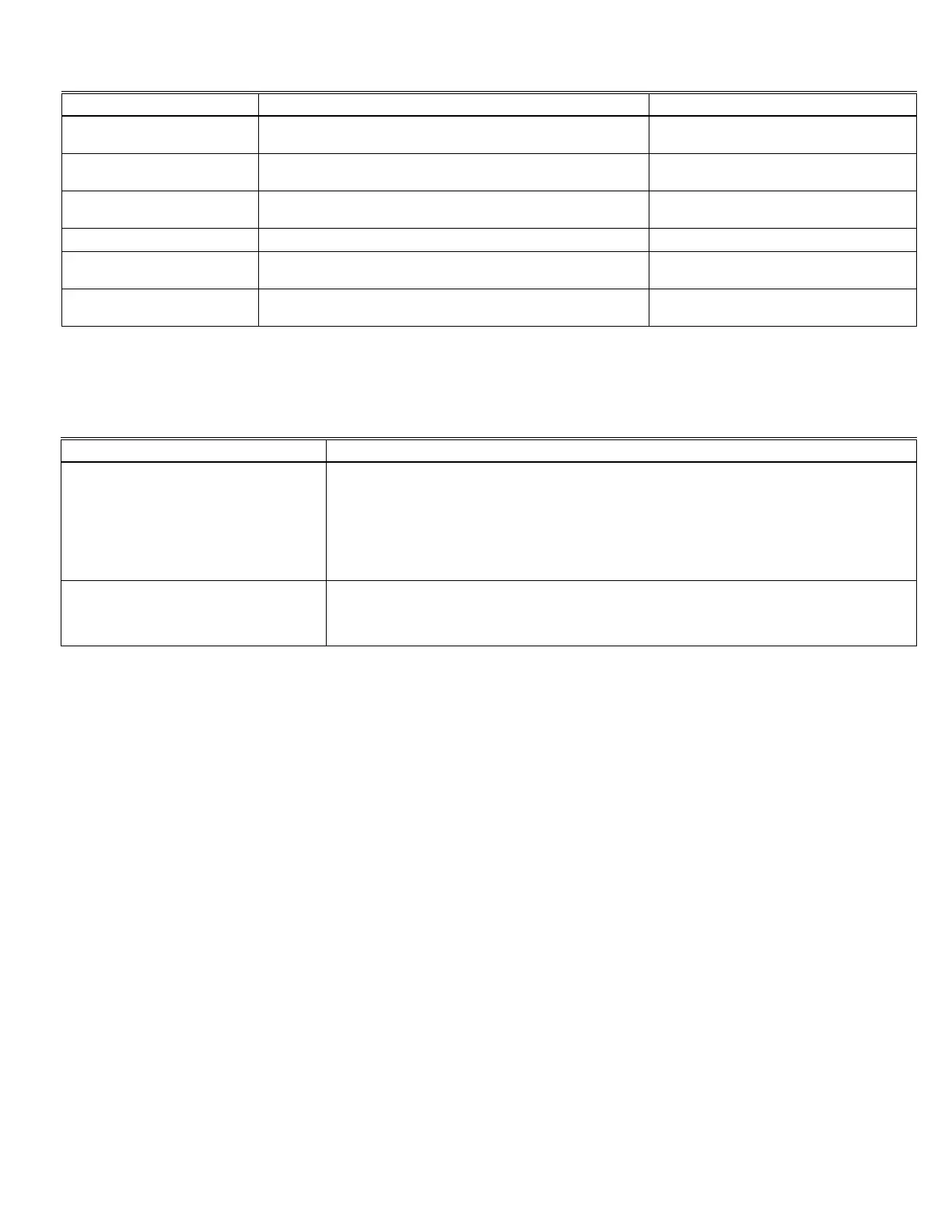

Table 1. Recommended Wire Sizes and Part Numbers.

Application Wire Size Recommended Recommended Part Numbers

Line voltage terminals. 14, 16 or 18 AWG copper conductor, 600 volt insulation,

moisture-resistant wire.

TTW60C, THW75C, THHN90C.

Keyboard Display Module 22 AWG two-wire twisted pair with ground, or five-wire. Belden 8723 shielded cable or

equivalent.

Data ControlBus™ Module

a

22 AWG two-wire twisted pair with ground, or five-wire. Belden 8723 shielded cable or

equivalent.

Remote Reset Module 22 AWG two-wire twisted pair, insulated for low voltage.

Communications Interface

ControlBus™ Module

a

22 AWG two-wire twisted pair with ground. Belden 8723 shielded cable or

equivalent.

13 Vdc full-wave rectified

transformer power input.

18 AWG wire insulated for voltages and temperatures for

given application.

TTW60C, THW75C, THHN90C.

a The KDM, Data ControlBus™ Module (for remote mounting or

communications) or Communication Interface Control-Bus™

Module must be wired in daisy chain configuration, 1(a)-1(a), 2(b)-

2(b), 3(c)-3(c). The order of interconnection of all the devices listed

above is not important. Be aware that modules on the closest and

farthest end of the daisy chain configuration string require a 120

ohm (1/4 watt minimum) resistor termination across terminals 1

and 2 of the electrical connectors for connections over 100 feet

(31 meters).

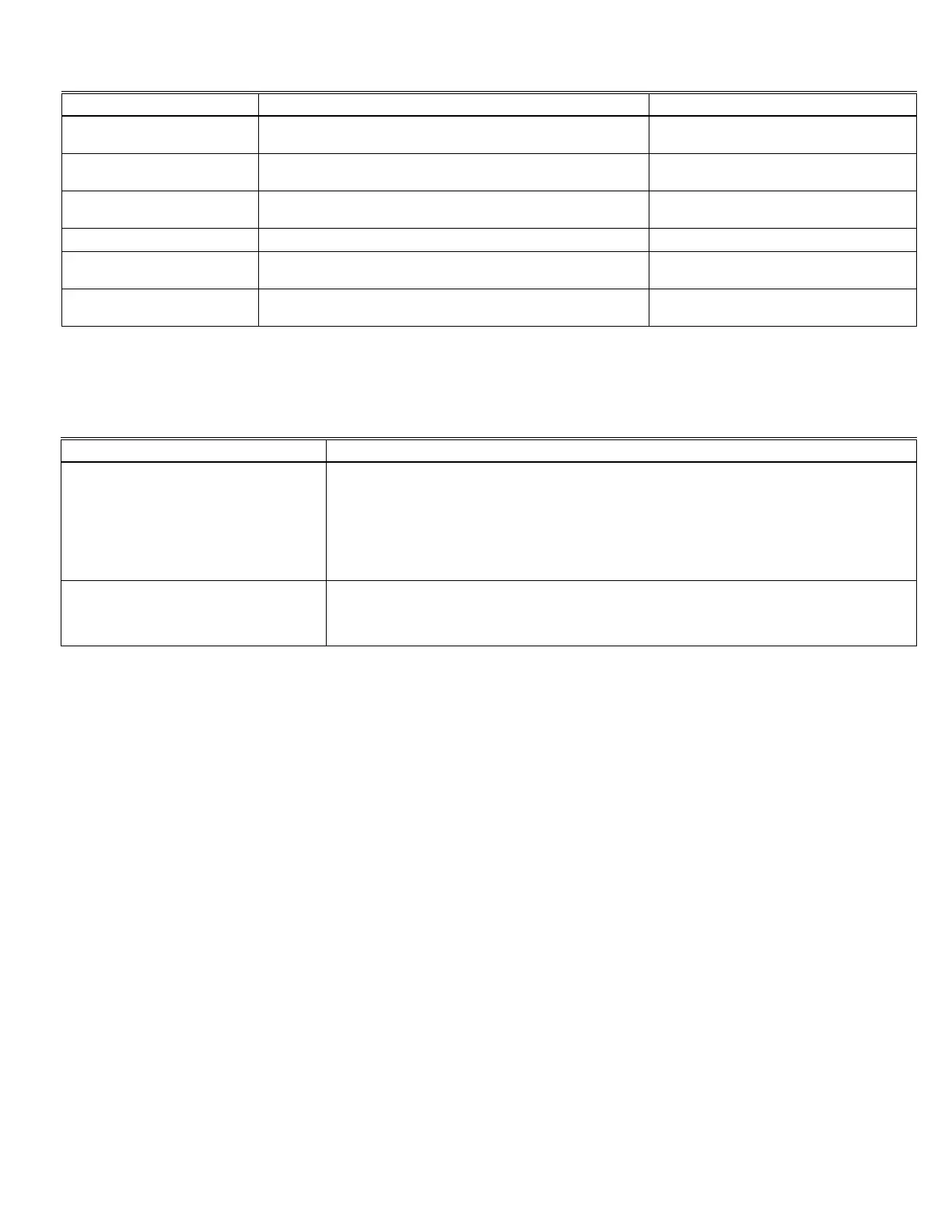

Table 2. Recommended Grounding Practices.

Ground Type Recommended Practice

Earth ground (subbase and relay

module).

1. Use to provide a connection between the subbase and the control panel of the

equipment. Earth ground must be capable of conducting enough current to blow the

20A fuse (or breaker) in the event of an internal short circuit.

2. Use wide straps or brackets to provide minimum length, maximum surface area

ground conductors. If a leadwire is required, use 14 AWG copper wire.

3. Make sure that mechanically tightened joints along the ground path are free of

nonconductive coatings and protected against corrosion on mating surfaces.

Signal ground (Keyboard Display

Module, Data ControlBus™ Module,

Communications Interface

ControlBus™ Module.

Use the shield of the signal wire to ground the device to the signal ground terminal 3(c)

of each device. Connect the shield at both ends of the daisy chain to earth ground.

7. Recommended wire routing of leadwires:

a. Do not run high voltage ignition transformer wires in the

same conduit with the flame detector, Data ControlBus

Module™, or Remote Reset Module wiring.

b. Do not route flame detector, Data ControlBus™ Module,

or Remote Reset Module leadwires in conduit with line

voltage circuits.

c. Enclose flame detector leadwires without armor cable in

metal cable or conduit.

d. Follow directions in flame detector, Data ControlBus™

Module, or Remote Reset Module Instructions.

8. The KDM is powered from a low voltage, energy limited

source. It can be mounted outside of a control panel if it is

protected from mechanical damage.

NOTE: A 13 Vdc power supply must be used any time more

than one KDM is used.

9. Maximum wire lengths:

a. RM7895A,B,C,D/EC7895A,C; RM7896A,B,C,D lead-

wires: The maximum leadwire length is 300 feet to ter-

minal inputs (Control, Running/Lockout Interlock).

b. Flame Detector leadwires: The maximum flame sensor

leadwire length is limited by the flame signal strength.

c. Remote Reset leadwires: The maximum length of wire is

1000 feet (305 meters) to a Remote Reset pushbutton.

d. Data ControlBus Module™: The maximum Data Con-

trolBus™ Module cable length depends on the number

of system modules connected, the noise conditions

and the cable used. The maximum length of all Data

ControlBus™ Module interconnecting wire is 4000 feet

(1219 meters).

10. Be sure loads do not exceed the terminal ratings. Re-

fer to the label on the RM7895A,B,C,D/EC7895A,C;

RM7896A,B,C,D or to the terminal ratings in Table 3.

Final Wiring Check

1. Check the power supply circuit. The voltage and frequen-

cy tolerance must match those of the RM7895A,B,C,D/

EC7895A,C; RM7896A,B,C,D. A separate power supply cir-

cuit can be required for the RM7895A,B,C,D/EC7895A,C;

RM7896A,B,C,D. Add the required disconnect means and

overload protection.

2. Check all wiring circuits and complete Static Checkout in

Table 6 before installing the RM7895A,B,C,D/EC7895A,C;

RM7896A,B,C,D on the subbase.

3. Install all electrical connectors.

4. Restore power to the panel.Test (except 7823 models)

Functional test:

Loading...

Loading...