V48A,F,J; V88A,J DIAPHRAGM GAS VALVES

60-2080—9 10

4. If there is still no voltage at the actuator, make sure all

the appropriate contacts in the thermostat (or

controller), limit(s), and flame safeguard control are

closed. If one or more is open, determine the cause(s)

and correct the con-dition(s) before proceeding.

5. If there is proper voltage at the valve actuator but the

valve still does not open, first check that the gas

pressure at the valve is normal. Then make sure that

the bleed line is unobstructed.

6. If the gas pressure and bleed line are okay but the valve

still does not open, replace the coil assembly. (Refer to

the Specifications section for the proper part number,

and to the Service Information section for the proper

procedure.)

7. If you replace the coil assembly and the valve still does

not open, replace the valve.

If the valve will not close when one or more of the

appropriate contacts in the thermostat (or

controller), limit(s), or flame safeguard control is

open:

1. Make sure that the gas flow is in the direction of the

arrow on the valve body.

2. Make sure the valve actuator is wired in the correct

circuit. Open the master switch to remove power from

the valve actuator. If the valve closes now, the actuator

may not be wired properly.

3. Look for a short in the electrical circuit.

SERVICE INFORMATION

WARNING

Electrical Shock Hazard.

Can cause severe injury or death.

1. Only qualified service technicians should attempt to

service or repair flame safeguard controls and

burner systems.

2. Open the master switch before replacing the coil

assembly or the valve. Line voltage is present in the

electrical circuits to the valve.

Scheduled Inspection and Maintenance

A schedule should be set up and followed for periodic

inspection and maintenance for the burner and all other

controls and the valve(s). Refer to the instructions for the

flame safeguard control for more information.

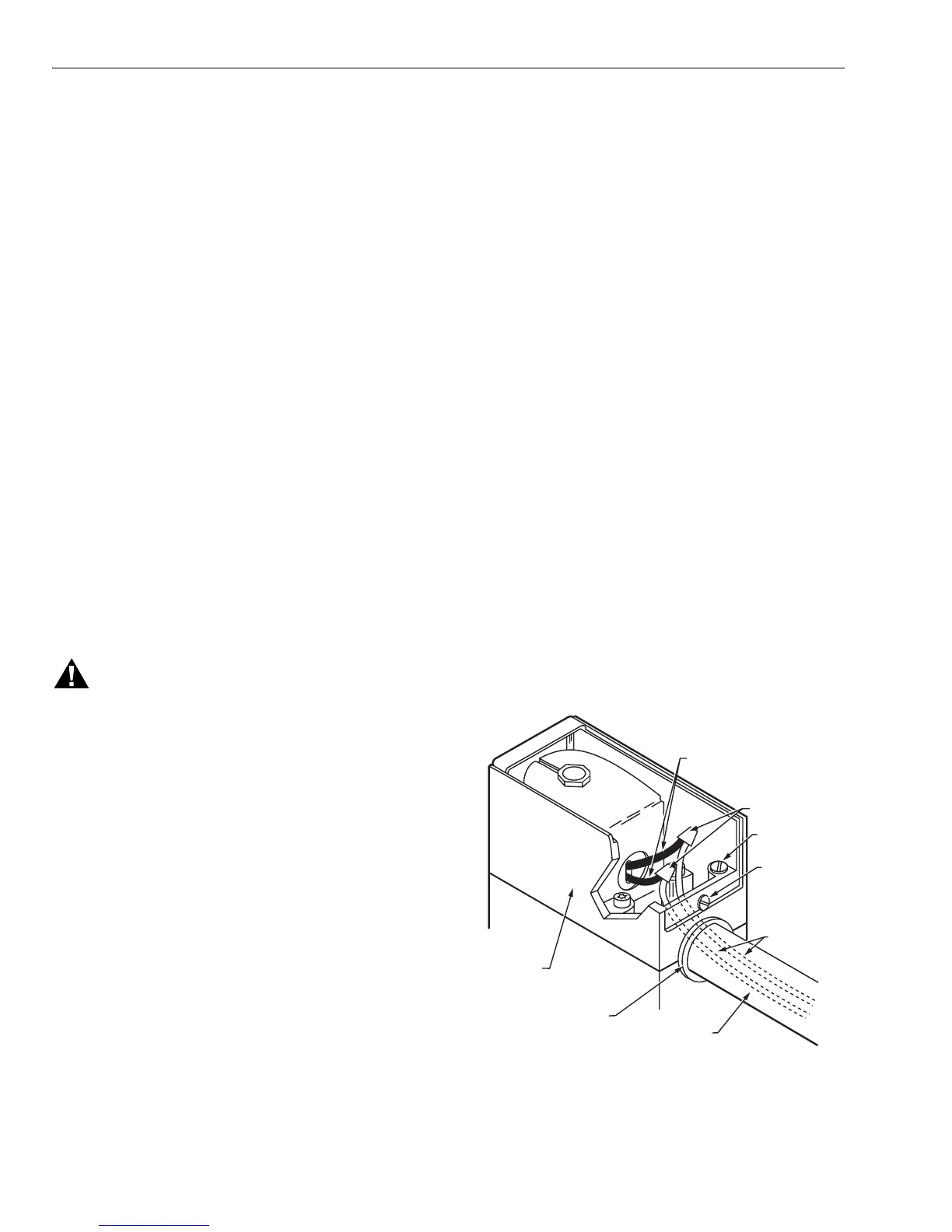

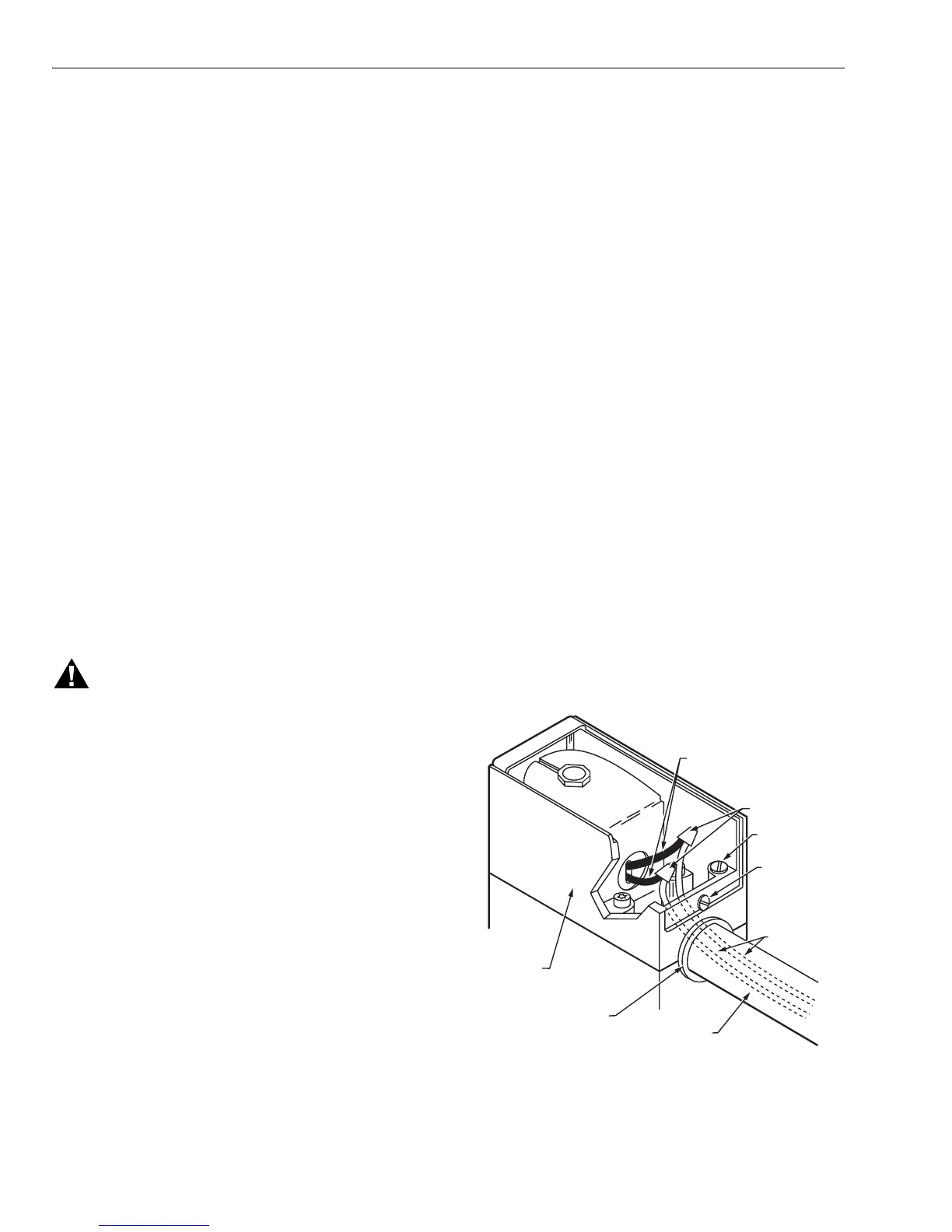

Replacing the coil assembly (Figs. 12

through 15)

1. Open the master switch to disconnect all power to the

valve actuator.

2. Loosen the cover screw in the front of the actuator

housing (Fig. 12) and remove the housing cover.

3. Disconnect the external wires from the two internal

black leadwires (Fig. 12).

4. Remove the two torx screws inside the actuator housing

(Fig. 13) and lift off the housing.

5. Remove the holding nut from the top of the coil

assembly (Fig. 13).

6. Lift the coil assembly straight up and off the plunger

tube assembly (Fig. 14).

7. Snap out the wraparound metal cover and remove the

metal base (Fig. 15). Save these parts for the

replacement coil.

8. Carefully unhook the cardboard insulator (Fig. 15) and

remove it. Save the insulator for the replacement coil.

9. Make sure the new coil assembly has the same part

number as the old one; then discard the old coil

assembly.

10. Wrap the cardboard insulator around the new coil

assembly and carefully hook it together around the two

black leadwires (Fig. 15).

11. Insert the two black leadwires through the opening in

the metal base, and insert the new coil assembly into

the metal base (Fig. 15).

12. Snap the wraparound metal cover into place around the

new coil assembly (Fig. 15).

13. Slip the new coil assembly over the plunger tube

assembly (Fig. 14).

14. Replace the holding nut on top of the coil assembly (Fig.

13) and tighten it securely.

15. Replace the actuator housing and tighten the two torx

screws holding it in place (Fig. 13).

16. Reconnect the external wires to the two internal black

leadwires (Fig. 12).

17. Replace the housing cover, and tighten the cover screw

holding it to the actuator housing (Fig. 12).

18. Close the master switch.

19. Test the valve to make sure it opens and closes as

described in the Operation section.

20. Verify proper operation after servicing.

Fig. 12. Wiring connections and actuator housing.

M7302

6 IN. [152.4 MM] INTERNAL

BLACK LEADWIRES

(FROM COIL)

SOLDERLESS

CONNECTORS

GROUNDING

SCREW

EXTERNAL

WIRES

ACTUATOR

HOUSING

OPENING IN

ACTUATOR

HOUSING

CONDUIT

(IF REQUIRED)

COVER

SCREW

Loading...

Loading...