V48A,F,J; V88A,J DIAPHRAGM GAS VALVES

9 60-2080—9

of the valve flows out through the bleed port. This reduces the

pressure on top of the diaphragm, allowing the gas pressure

below to lift the diaphragm and open the valve.

When all the gas has bled off the top of the diaphragm, the

valve is fully open, permitting gas flow to the main burner.

After the controller is satisfied, the procedure is reversed. The

controller contacts open so the coil is de-energized. The

plunger is released, moving to the DOWN position. This

closes the bleed port and opens the supply port so gas flows

again into the top port of the valve. As the gas pressure on top

of the diaphragm increases, the diaphragm begins to close.

When the pressures on both sides of the diaphragm are

balanced, the valve will be closed. The weight and spring help

to close the valve. If the gas supply fails and there is no

pressure below the diaphragm, the weight and spring will

close the valve.

In the event of a power failure during automatic operation, all

V88 and V48 valves will close. Normal operation will be

resumed upon power restoration.

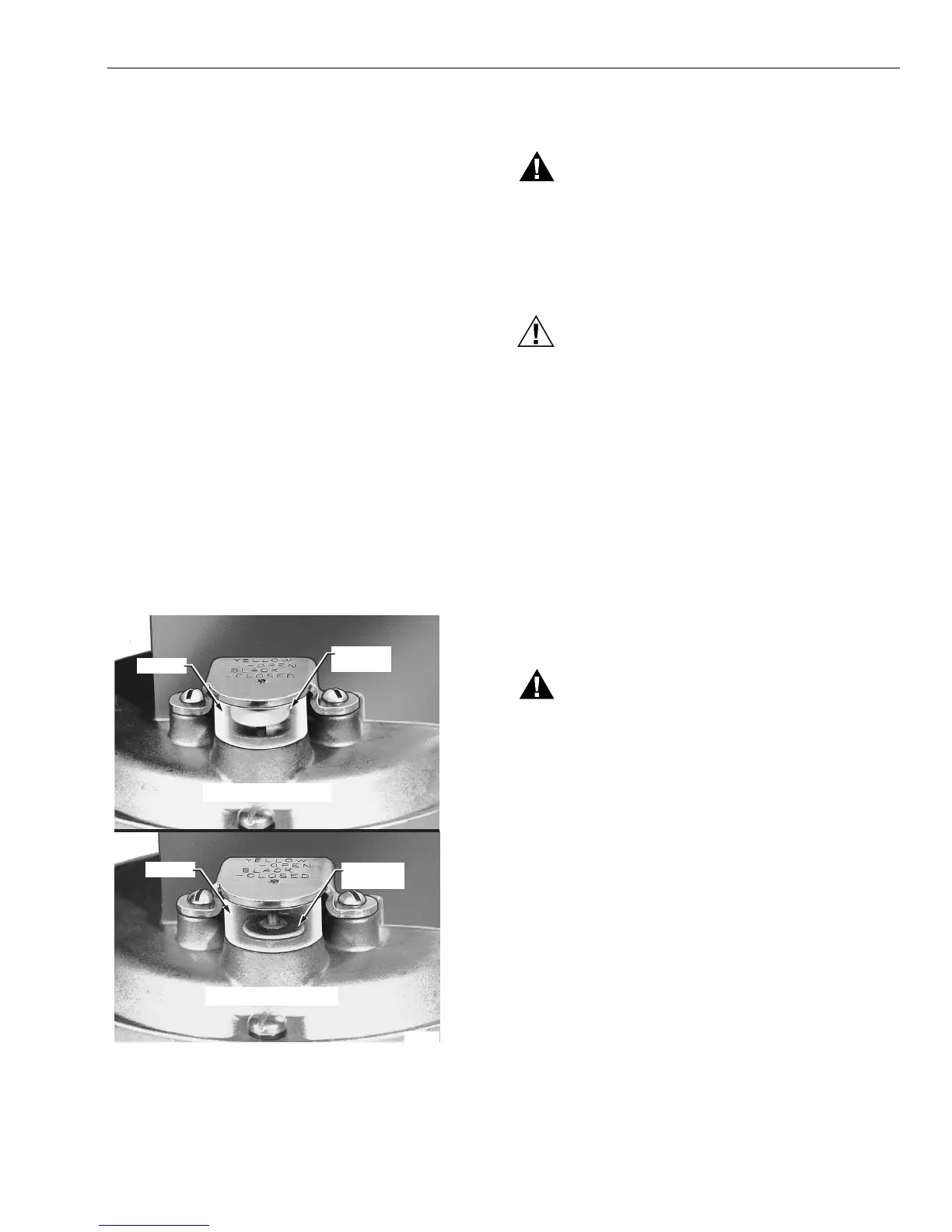

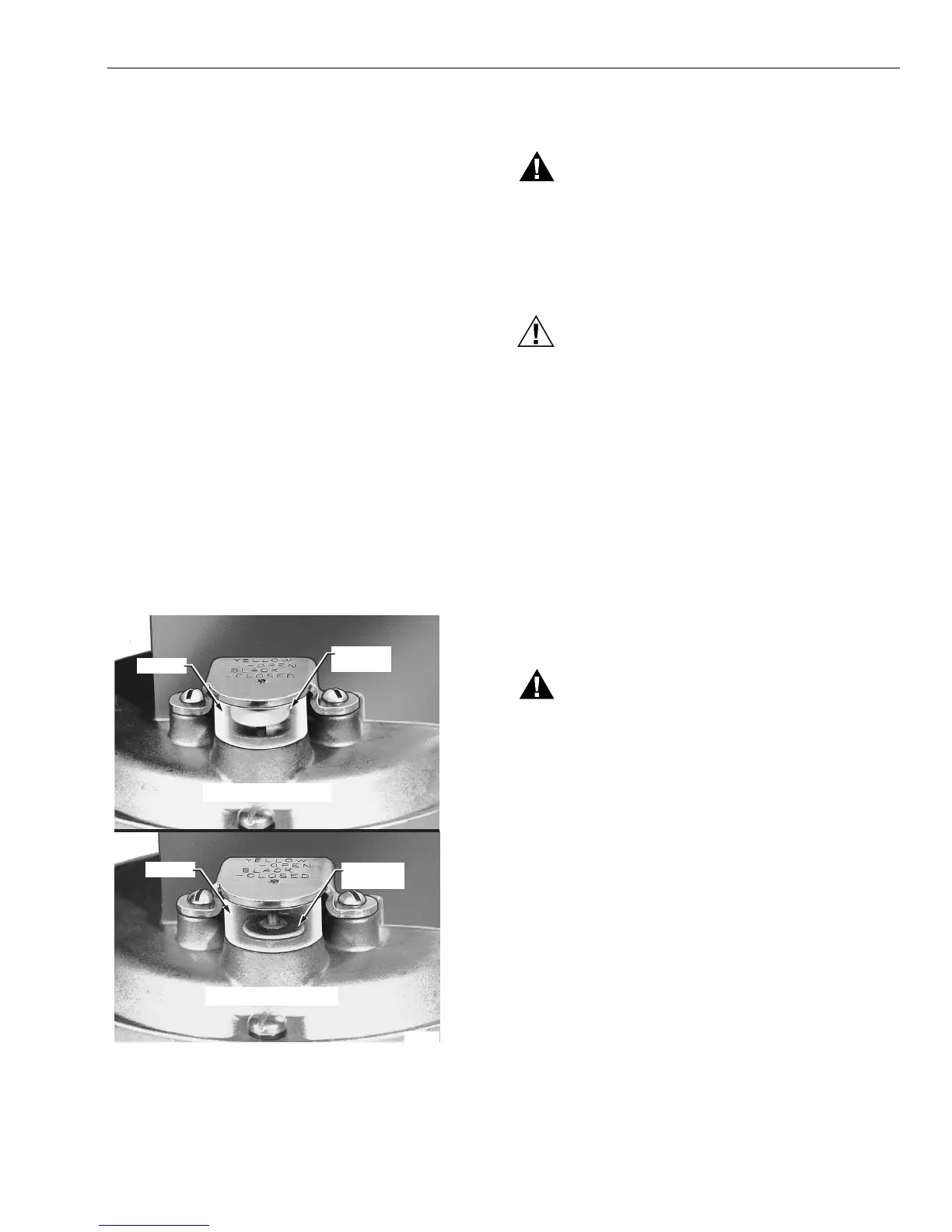

Operation of the Valve Position Indicator

(Fig. 11)

An optional valve position indicator is available in the 1-1/4 in.

V48A2227 and 2 in. V48F1103 Valves. When the valve is

open, a yellow disk shows in the window. When the valve is

closed, only the black top of the disk is visible.

Fig. 11. Valve position indicator (optional).

CHECKOUT AND TROUBLESHOOTING

WARNING

Explosion Hazard.

Can cause severe injury, death or property

damage.

Do not allow fuel to accumulate in the combustion

chamber. If fuel is allowed to enter the chamber for

longer than a few seconds without igniting, an

explosive mixture could result.

CAUTION

Equipment Damage Hazard.

Can cause equipment damage and improper

operation.

1. Do not put the system into service until you have

satisfactorily completed all applicable tests

described in the Checkout section of the

instructions for the flame safeguard control, and any

other tests required by the burner manufacturer.

2. Close all manual fuel shutoff valves as soon as

trouble occurs.

Checkout

Start the system and observe its operation through at least

one complete cycle to be sure the valve functions as

described in the Operation section.

Troubleshooting

WARNING

Electrical Shock Hazard.

Can cause severe injury or death.

Use utmost care during troubleshooting. Line voltage

is present at the actuator for a V48 Valve, and is

present in all controller circuits for all V48 and V88

Valves.

IMPORTANT:

Do not assume that the valve must be replaced until

all other sources of trouble have been eliminated.

If the valve will not open when the thermostat or

controller is calling for heat:

1. Check that there is voltage at the valve actuator (black

leadwires, Fig. 7). Be careful—there should be line

voltage at the actuator of a V48.

2. If there is no voltage at the actuator, first make sure line

voltage power is connected to the master switch, the

master switch is closed, and overload protection (circuit

breaker, fuse, or similar device) has not opened the

power line.

3. For a V88 only: If a line voltage power is okay, check the

transformer. Replace it if necessary.

WINDOW

YELLOW

DISC

BLACK TOP

OF DISC

VALVE OPEN

VALVE CLOSED

WINDOW

M18856

Loading...

Loading...