V9055A,D MODULATING FLUID POWER GAS VALVE ACTUATOR

5 60-2311-11

Install Accessory Switches (If Needed)

An spdt switch may be installed to operate an auxiliary load of

up to 1/2 hp. The switch may be adjusted to operate at any

point in the valve stroke. A proof-of-closure switch may also be

installed. The proof-of-closure switch must be used with the

V5055 C,E/V5097C,E (two seals) Valve to provide valve seal

overtravel interlock.

The spdt proof-of-closure switch is installed to make or break a

circuit when the valve is in the closed position. The switch is

not adjustable.

NOTE: Mark the actuator or valve to indicate any changes

made.

To install the switches, proceed as follows:

1. Remove the actuator faceplate (two screws).

2. Remove the silver-colored barrier to expose the actuator

stem.

3. Insert the auxiliary switch in the position indicated in

Fig. 3. Fasten with two screws through the actuator base.

4. Insert the proof-of-closure switch in the position shown in

Fig. 3. The proof-of-closure switch mounts against the

side of the actuator housing. The mounting holes are

spaced to mount the switch only in the correct position.

Fasten with two screws through the actuator base.

5. If only one switch is used, install the narrow barrier

included with the switch in the unused space.

6. Mount the actuator before making wiring connections

and adjustments to the switch.

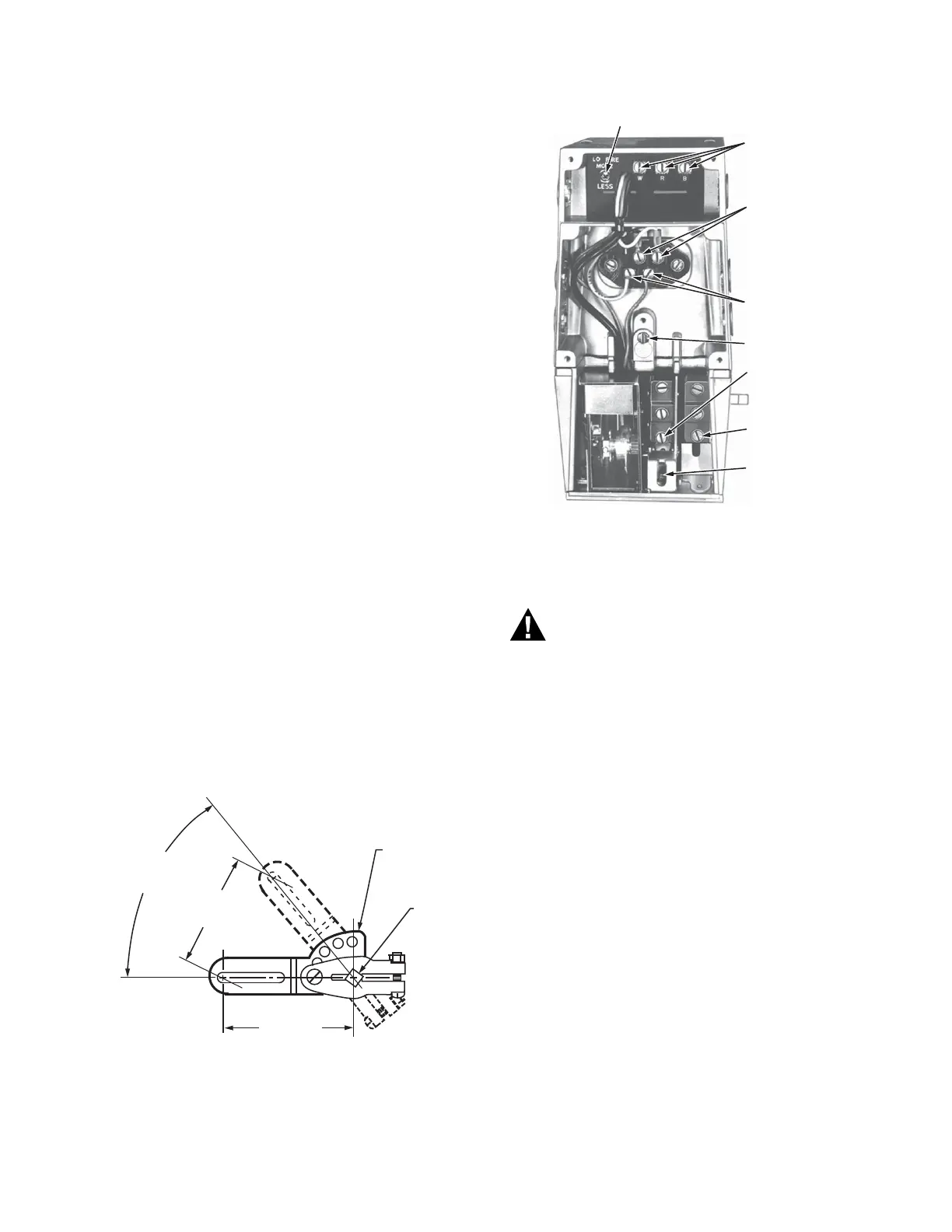

Mount and Adjust Damper Crank Arm

IMPORTANT:

When a damper crank arm is used with a NEMA 4

actuator that is exposed to ice or sleet, a suitable

shield must be installed to prevent ice or sleet buildup.

The crank arm provides a maximum travel of 2-5/16 in.

(59 mm). For complete installation information, refer to the

instructions packed with the 7616BR Crank Arm.

Fig. 2. Crank Arm Operation.

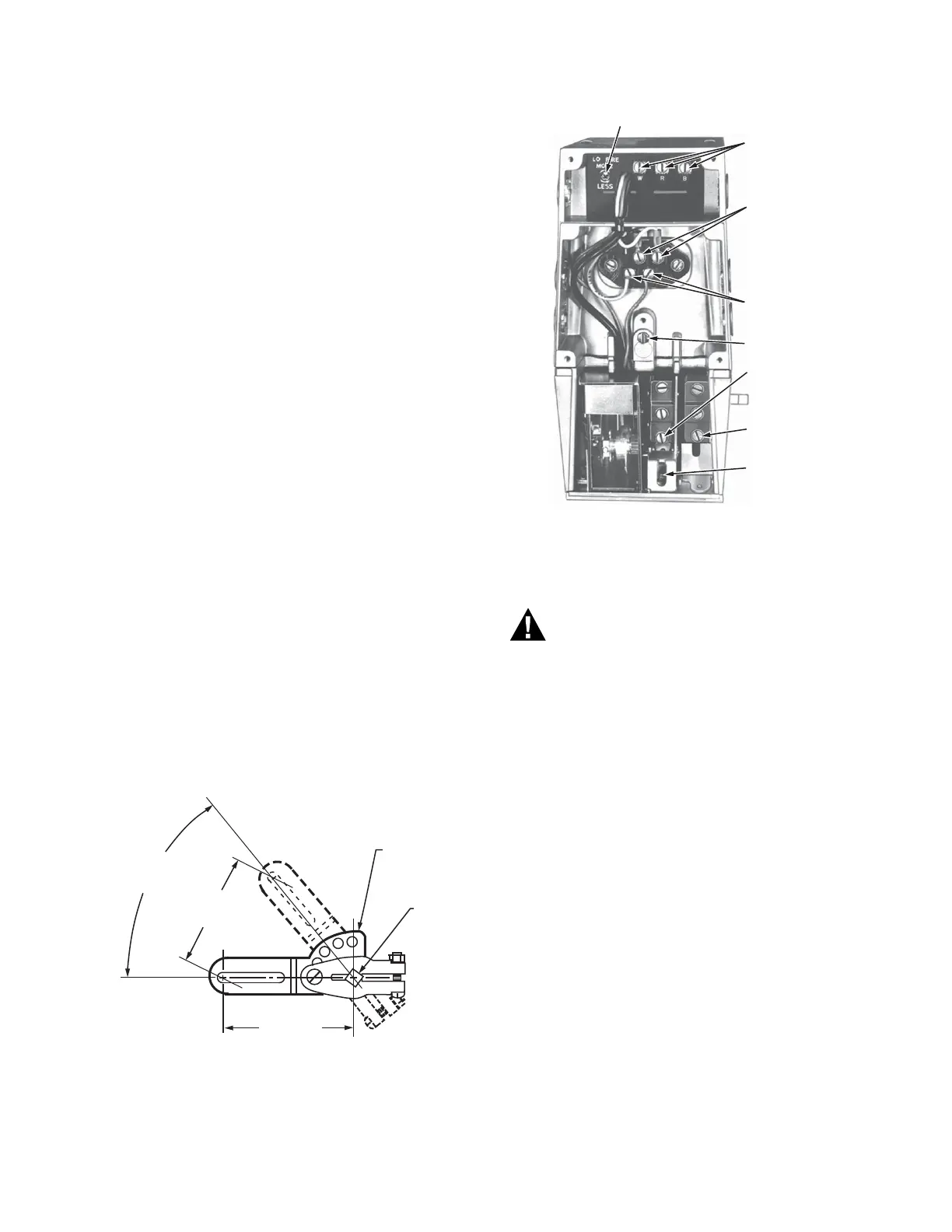

Fig. 3. Internal components and connections in V9055.

WIRING

Electrical Shock Hazard.

Can cause serious injury, death or equipment damage.

To prevent electrical shock or equipment damage

disconnect power supply before wiring.

All wiring must agree with applicable electrical codes and

ordinances.

Connect power supply to terminals 1 and 2 on the terminal

strip. Do not make any connections to the unmarked terminals

shown in Fig. 3.

NOTE: When replacing a V9034, remove the 24 volt trans-

former because V9055 has a built-in transformer.

When replacing a V9034 Actuator with a V9055,

replace the V5034 Gas Valve with a V5055/V5097

Valve.shown in Fig. 3.

NOTICE: Per Industry Standards, the actuator is required a

conduit seal or a cable type that is sealed be installed in a

device that can result in a flammable liquid flow through a

conduit or cable to an electrical ignition source in the event of a

seal leakage or diaphragm failure.

52 DEGREE

ANGULAR

ROTATION

MAXIMUM

TRAVEL

SHAFT

7616BR

DAMPER

ARM

M7322A

RADIUS

2-11/16 (68.3)

2-5/16 (58.7)

LOW FIRE ADJUSTMENT

CONNECTIONS

TO SERIES 90

PROPORTIONING

CONTROLLER

LINE VOLTAGE

POWER SUPPLY

CONNECTIONS

DO NOT MAKE ANY

CONNECTIONS

TO THESE TERMINALS

GROUND SCREW

AUXILIARY

SWITCH

PROOF-OF-CLOSURE

SWITCH

ADJUSTING SCREW

FOR AUXILIARY

SWITCH

M7320

Loading...

Loading...