V9055A,D MODULATING FLUID POWER GAS VALVE ACTUATOR

7 60-2311-11

OPERATION

To function as intended, the V9055 must be connected to a

properly sized valve. The proper sized V5055/V5097B Gas

Valve with characterized guide is recommended for optimum

control and low-fire repeatability. Too large of a valve will not

properly modulate the gas flow. When the actuator is

energized, it will drive at least to the adjusted low-fire position.

The distance it will open beyond this low-fire position depends

on the demands of the modulating controller.

When the controller calls for no heat, the actuator will modulate

the valve to the low-fire position. When power to the actuator is

interrupted, the valve will completely close.

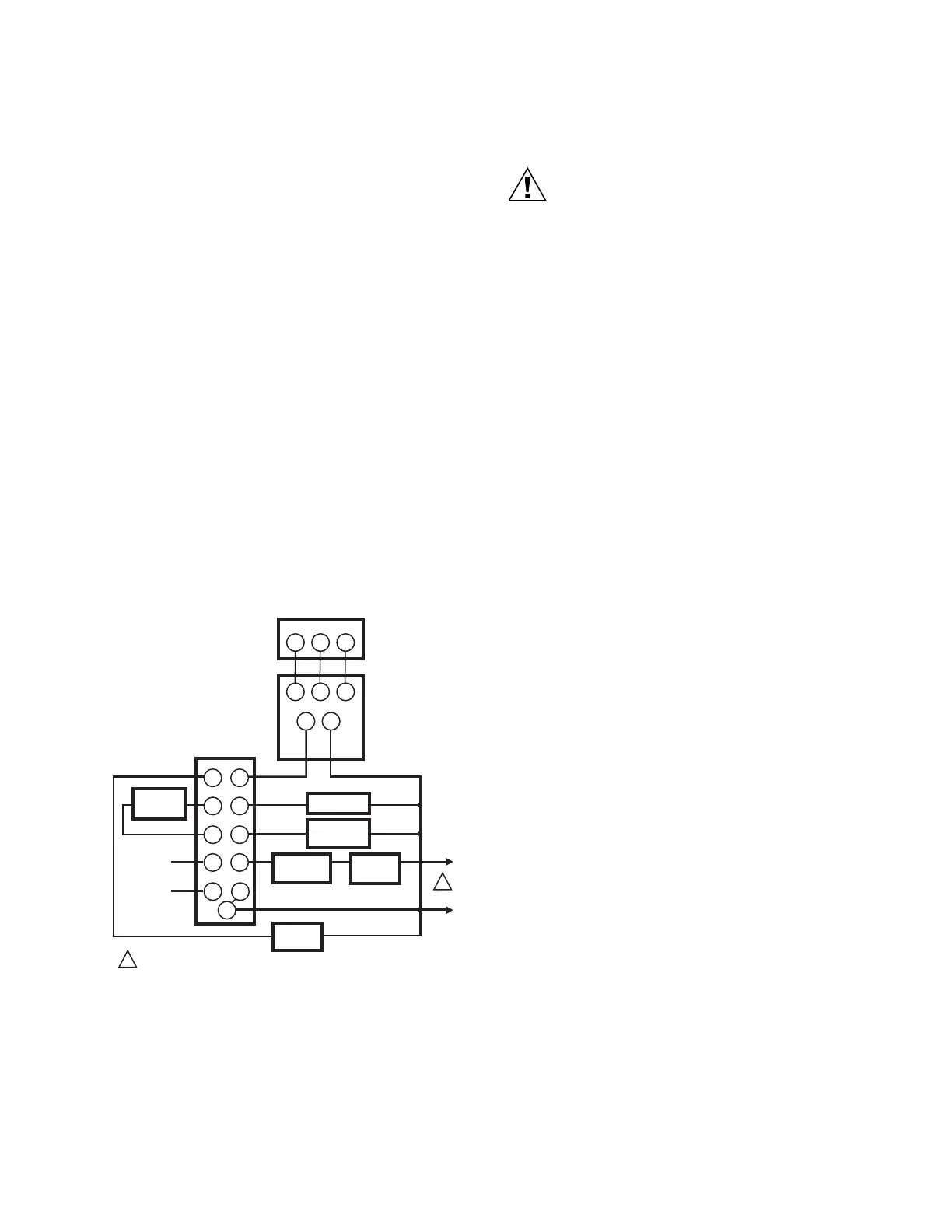

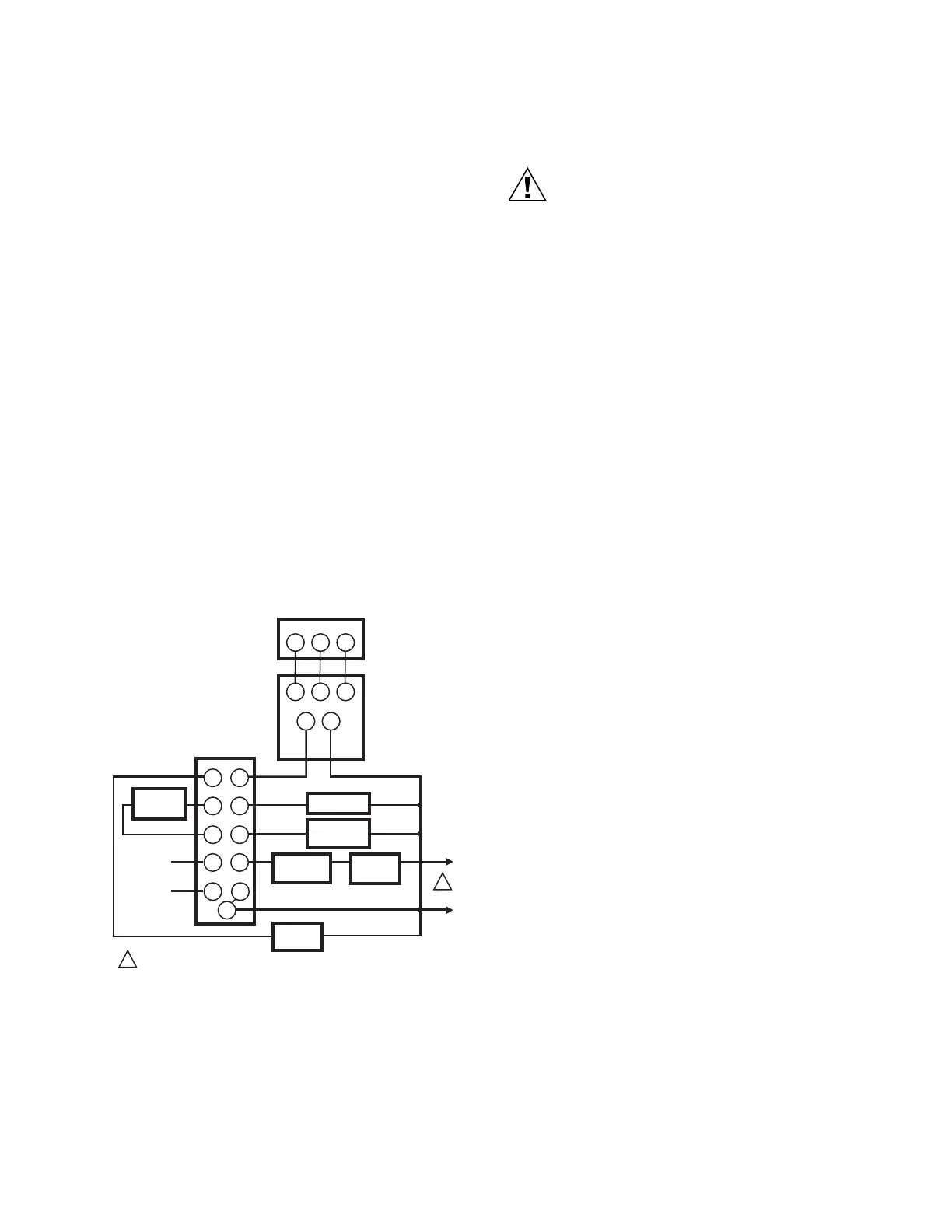

Fig. 6 shows the V9055 in a typical flame safeguard control

system.

CHECKOUT AND SERVICE

Checkout

IMPORTANT

Only a trained, experienced flame safeguard control

technician should service or repair this control.

After the valve installation is complete, cycle the valve a few

times with the manual fuel shutoff cock closed before testing

the system in actual operation.

Fig. 6. V9055 connected to R4795 in typical application.

Service

The actuator is not field repairable except for replacing the

auxiliary switch. See Install Accessory Switches section for the

procedure.

Do not disassemble the valve actuator. Perform the following

checks before removing and replacing the V9055 Gas Valve

Actuator.

1. With manual gas valve closed, energize the V9055 and

check for voltage on terminals 1 and 2. Actuator should

modulate to the low-fire position.

Equipment Damage Hazard.

Improper wiring can damage the equipment and cause

injury to personnel.

Label all wires prior to disconnection when servicing

valves. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

2. Disconnect the leads from the modulating controller (ter-

minals W,R, and B). Connect a manual potentiometer,

color-to-color, to terminals W, R, and B on the actuator.

With the valve energized, use the potentiometer to open

and close the actuator. It should run from the low-fire

position and to the fully open position.

If the actuator fails to operate properly, replace it:

1. Turn off the gas supply at the manual shutoff valve

located upstream from the valve(s) being serviced.

2. Shut off all electrical power to the valve actuator(s).

3. Mark and disconnect the wires from the actuator termi-

nals. Remove conduit and disengage the damper linkage

assembly (if applicable).

4. Loosen the two set screws from the valve to lift off the

actuator.

5. If the actuator is to be replaced and it did not leak

hydraulic fluid, skip to Step 11.

NOTE: It is good practice to inspect the inside of the

valve whenever the actuator is replaced. To do

so, remove the bonnet assembly, inspect the

valve and bonnet. If all is well, proceed to Step

7.

6. If the actuator leaked hydraulic fluid onto the valve (the

fluid is red), it must be cleaned off from the valve and

bonnet assembly.

a. Wipe off the outer valve body.

b. Remove the valve bonnet bolts and lift off the bonnet.

NOTE: V5055/V5097C and E Valves have additional

internal springs that will push the bonnet up as

the bolts are loosened.

c. Inspect the inside of the valve.

IMPORTANT

If fluid is present on the inside surfaces of the valve

body or bonnet surfaces, the bonnet assembly or

entire valve must be replaced. See Table 5 below for

the bonnet assembly part number.

d. If the inside surfaces are clear of hydraulic fluid,

clean the bonnet assembly and be sure to remove all

hydraulic fluid from the inside and outside of the

actuator mounting curb. This is the “cup-like” area

around the valve stem. Avoid using a cleaning solu-

tion as it may damage the rubber seals used in the

valve.

8

7

6

F

G

X

X

2

5

4

3

1

WRB

W

R

B

12

V9055

ACTUATOR

SERIES 90

PROPORTIONING

CONTROLLER

R4795 FLAME SAFEGUARD

PRIMARY CONTROL

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

AIR

SWITCH

IGNITION

PILOT

VALVE

CON-

TROLLER

LIMIT

L1

(HOT)

L2

FLAME

DETECTOR

FAN

MOTOR

M7324

Loading...

Loading...