Do you have a question about the Honeywell V9055A and is the answer not in the manual?

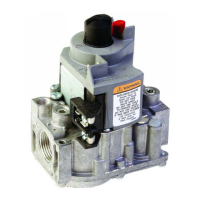

| Brand | Honeywell |

|---|---|

| Model | V9055A |

| Category | Controller |

| Language | English |

Details the maximum force for damper arms driven by the actuator under various temperature conditions.

Specifies the actuator shaft size and compatibility with damper arms, including optional return springs.

Defines the operational temperature range for 60 Hz and 50/60 Hz models.

Describes how the actuator attaches to the valve and mounting flexibility.

Provides diagrams and tables for physical installation dimensions of the actuator and valve.

Details critical safety warnings related to electrical shock during installation and servicing.

Guidance on mounting the actuator onto the valve, considering clearance and ambient conditions.

Important consideration for NEMA 4 actuators exposed to ice/sleet when using a damper crank arm.

Instructions for installing auxiliary and proof-of-closure switches for enhanced functionality.

Details on mounting and adjusting the damper crank arm for synchronized valve and damper operation.

Guidance on connecting power supply and controller signals to the actuator, including safety precautions.

Installation and hookup procedure for the 203422C adapter for 4-20 mA control input.

Procedure to adjust the actuator's low-fire position for optimal burner lightoff and repeatability.

How to adjust the auxiliary switch to operate at specific points within the actuator stroke.

Steps for verifying actuator operation and system functionality after installation and wiring.

Detailed procedure for removing and replacing the V9055 actuator, including safety checks.

Instructions for ensuring proper bonnet seal and leak prevention after service or replacement.

Loading...

Loading...