13 / 14

5.2 Maintentance

The pneumatic actuators are low-maintenance.

The guide (10) and the membranes (4) are consumables have to be replaced if necessary.

To ensure continuous readiness for use of the manual positioning, we recommend to check the greasing

situation of the threaded spindle (32) every 3 months and, if necessary, put grease directly onto the thread.

The spindle is lubricated at the factory. For this the lubricant KLÜBERPLEX BE 31-502 by

KLÜBER/LUBRICATION is used. When using a different, at least equivalent lubricant, all parts that are in

contact with the lubricant must be cleaned thoroughly before re-lubricating, so that mixing and possible

reaction of the two lubricants is excluded. As alternative lubricant we recommend Oest EP by Oest.

Attention: When using other lubricants or when mixing different lubricants the manufacturer

shall not be liable for possible sequential damage.

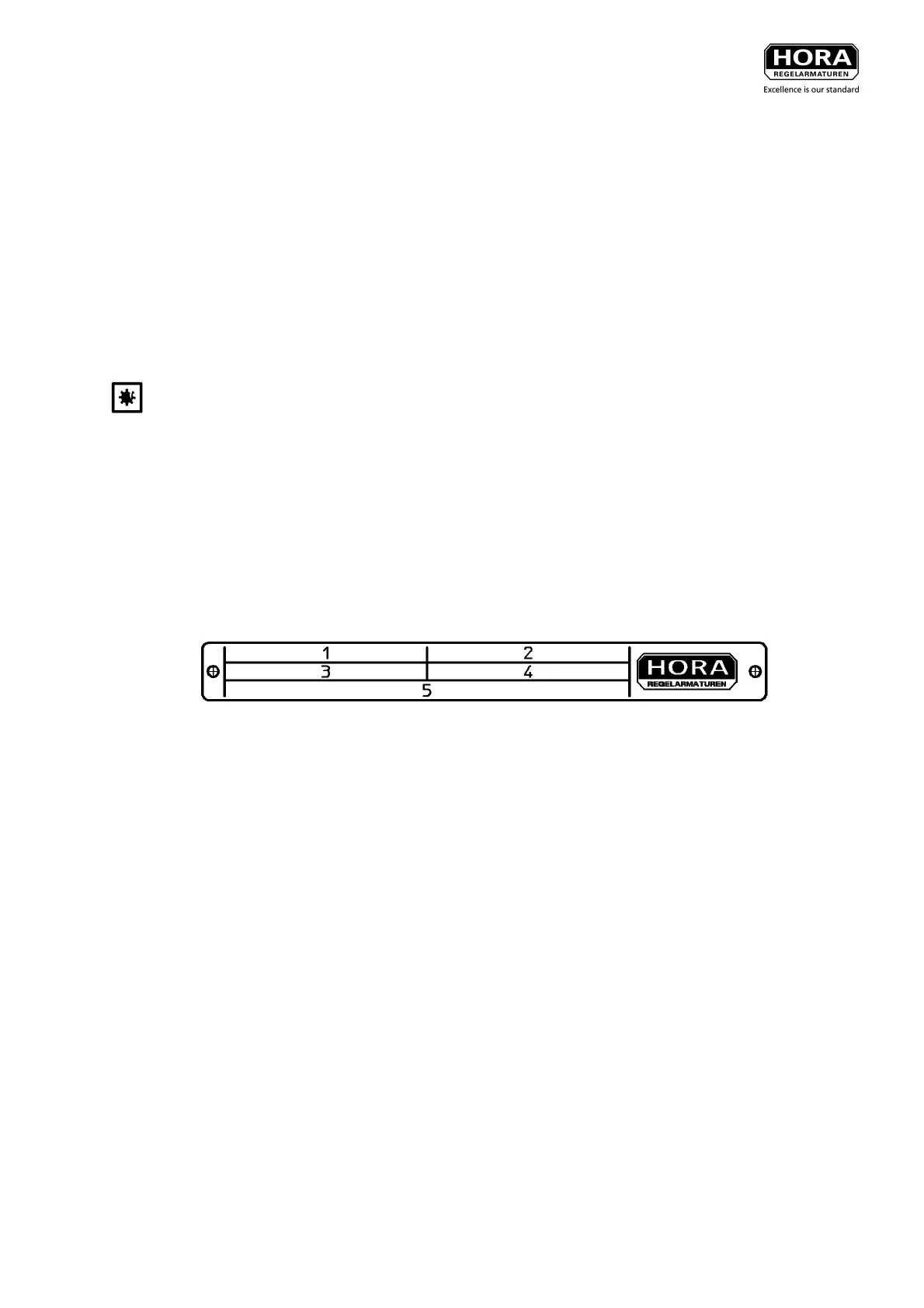

When ordering spare parts, state the information given on the type label (see picture 4):

• Man. no. (picture 4 field 1)

• Type (picture 4 field 2)

• Spring (picture 4 field 3)

• Input air pressure (picture 4 field 4)

• Function (picture 4 field 5)

Picture 4: Type plate

Loading...

Loading...