19 / 19

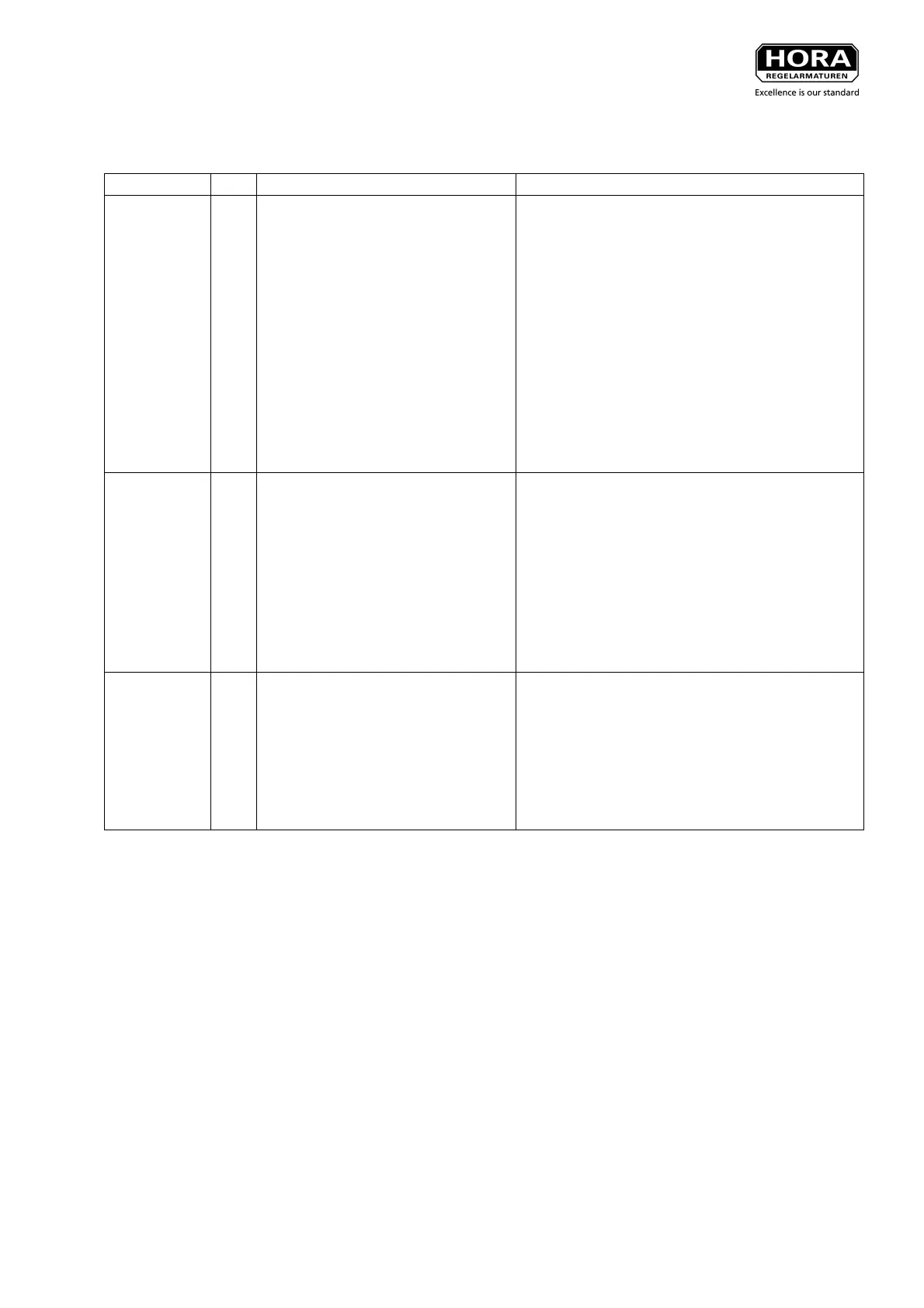

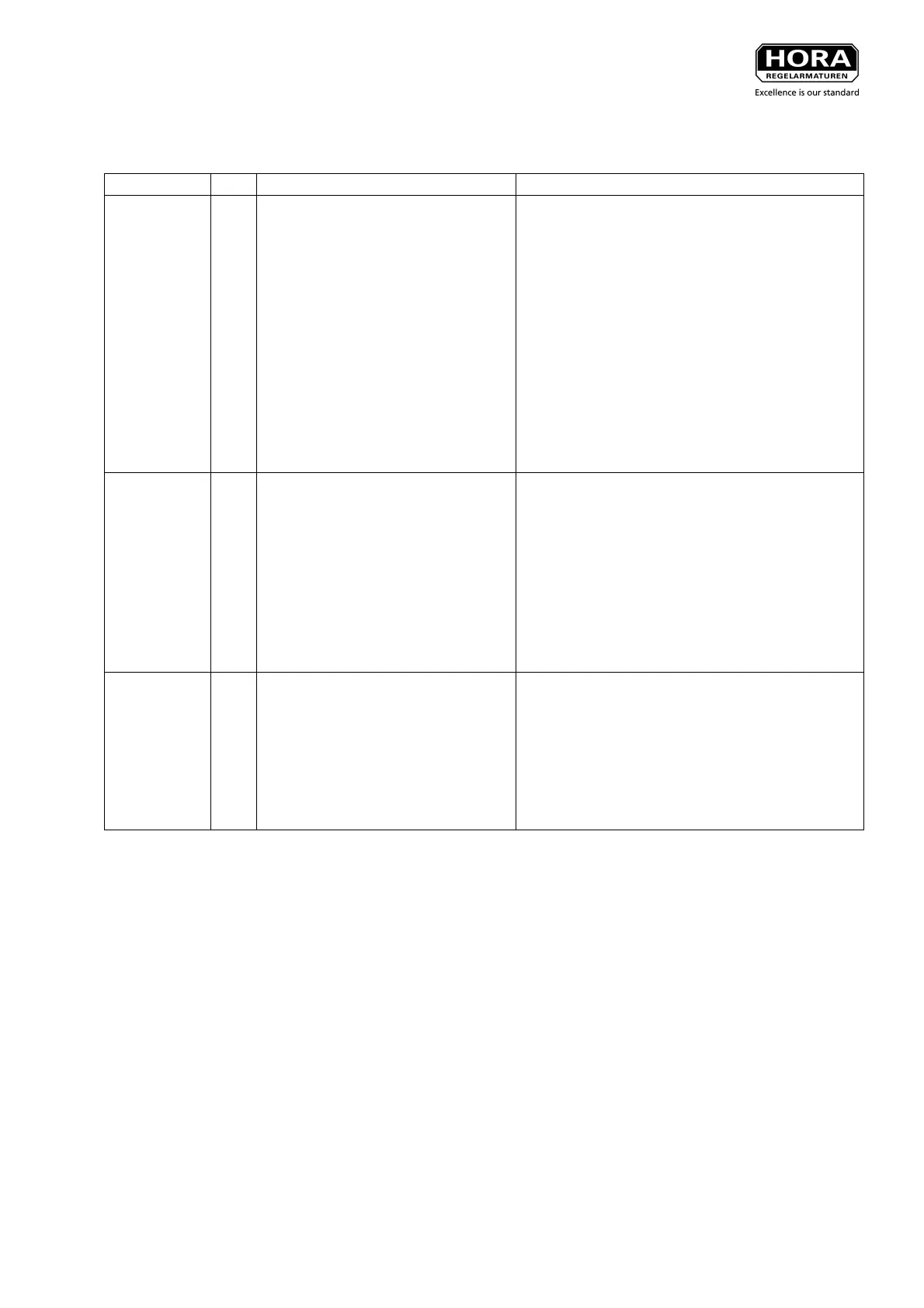

6 Troubleshooting List

Fault No. Possible Cause Measures

Actuator

spindle not

moving

1.1

1.2

1.3

1.4

1.5

• Manual control not in zero

position.

• Compressed air not connected

to actuator.

• Diaphragm is torn.

• Valve cone seized.

• Design actuator power is too

weak for the valve.

• Bring the manual control into the zero

position (see Chapter 5.1)

• Check compressed air system.

• Change diaphragm.

• See Valve Troubleshooting List.

• Check design and consult the manufacturer

of the whole valve.

Movement of

actuator

spindle jerky

2.1

2.2

2.3

• Too little compressed air.

• Position control system set

incorrectly.

• Valve cone seized slightly due

to dirt particles.

• Check compressed air system for damage

and sufficient throughput.

• Correct the settings (see Operating

Instructions for position control system).

• See Valve Troubleshooting List.

High air

consumption

3.1

3.2

3.3

• Diaphragm not compressed

correctly.

• Seal components worn.

• Leaky pipes to actuator.

• Tighten hexagonal nuts (21) until the

diaphragm is compressed.

• Change seal components (10 & 11, plus 3 if

necessary).

• Check pipes for leaks and change or seal as

necessary.

If the remedies stated above lead nowhere contact the supplier / manufacturer.

Loading...

Loading...