17

Operations

Inspection and Testing Gas Piping

The building structure should not be weakened by

installing the gas piping. The piping should not be

supported by other piping, but should be firmly

supported with gas hooks, straps, bands or hangers.

Butt or lap welded pipe should not be run through or in

an air duct or clothes chute.

Before turning gas under pressure into piping, all

openings from which gas can escape should be closed.

Immediately after turning on gas, the system should be

checked for leaks. This can be done by watching the

1/2 cubic foot test dial for 5 minutes for any movement

or by soaping each pipe connection and watching for

bubbles. If a leak is found, make the necessary repairs

and repeat the above test.

Defective pipes or fittings should be replaced and not

repaired. Never use a flame or fire in any form to locate

gas leaks — use a soap solution.

After the piping and meter have been checked

completely, purge the system of air. DO NOT bleed the

air inside an enclosed room.

During pressure testing of the system at test pressures

in excess of 1/2 PSIG, the pressure washer and its indi-

vidual shut-off valve must be disconnected from gas

supply piping system or damage to the gas valve will

occur.

Gas Pressure

The ideal incoming gas pressure is 11 w.c.i (water

column inches). Minimum is 9 w.c.i., maximum is 14

w.c.i. or 1/2 PSIG. The correct operating manifold

pressure for natural gas is 2.8 w.c.i. The operating

manifold pressure for propane gas is 7.5 w.c.i. By

adjusting the gas valve pressure regulator between 3

and 4 w.c.i. a side range can be achieved for natural

gas.

If the desired input rating cannot be obtained within the

above manifold pressure adjusting range, then the next

size larger or smaller burner orifice should be used.

The gas pressure coming out of the regulator and going

to the burner ring has been factory set for elevations of

0 to 2000 ft. Altitudes greater than 2000 ft will require

adjustments to the gas manifold pressures. Consult

your local service dealer for high altitude adjustments.

In Canada, certification for installation at altitudes over

4500 feet above sea level is the jurisdiction of local

authorities. You should not readjust the burner ring gas

pressure. If you replace your gas valve, you will need to

adjust the new valve. Refer to your machine’s specifi-

cation plate for the correct pressure setting. Follow the

installation and adjustment instructions provided with

your replacement valve.

NOTE: Air for combustion and ventilation along with

exhaust flue sizing must conform to methods outlined in

current American Standard (ANSI-Z223.1) National

Fuel Gas Code or National Standard of Canada CSA-

149.1 and CSA-149.2 “Installation Code for Gas

Burning Appliances”.

Hotsy 900/1400 Series Dealer Manual 9.803-324.0 - AW

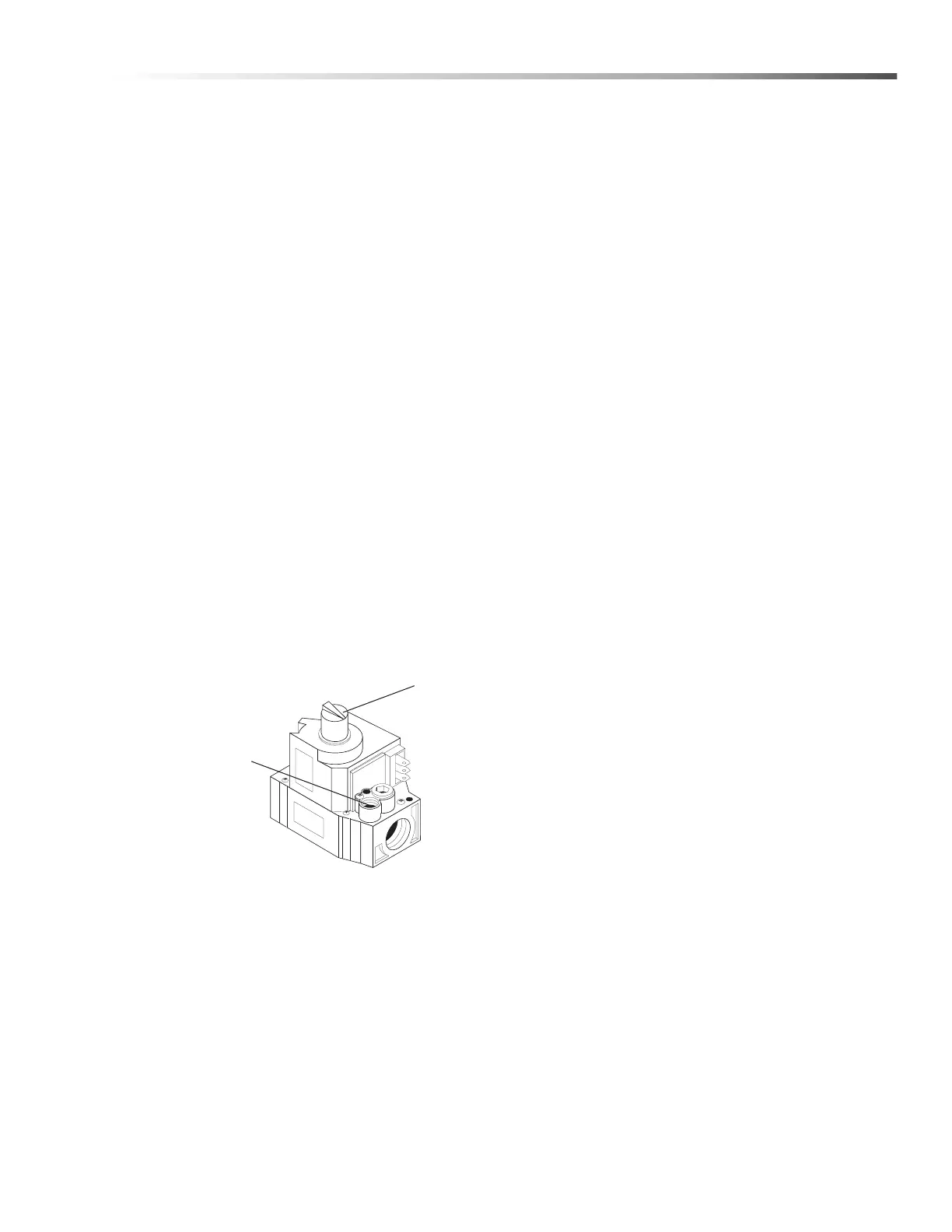

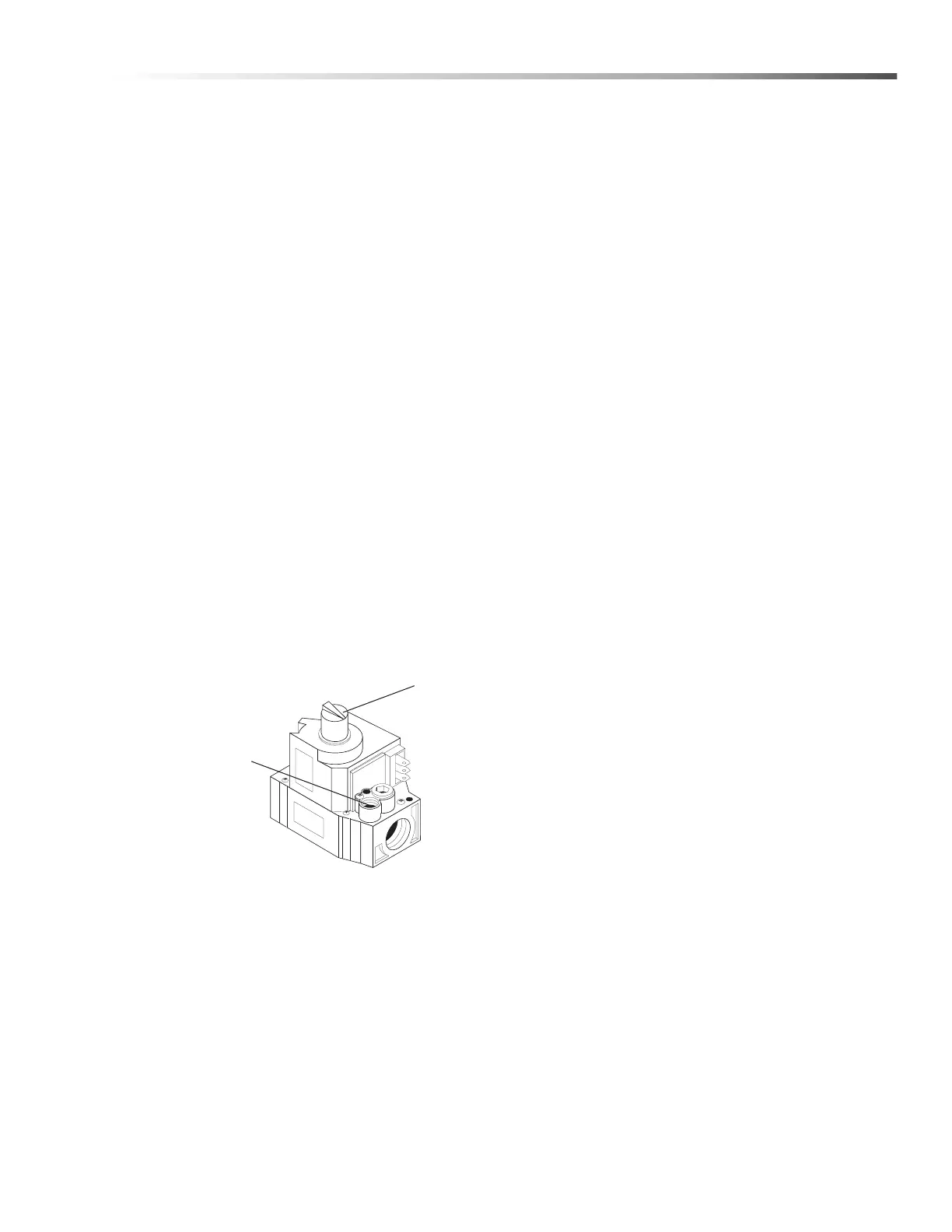

On/Off

Switch

Manifold

Pressure Adjustment

Screw Under Cap

Loading...

Loading...