The DTSU666-HW Smart Power Sensor is a versatile device designed for precise energy measurement and monitoring in various electrical systems. It serves as a crucial component for understanding and managing power consumption, offering functionalities suitable for both direct connection and integration with current and potential transformers.

Function Description

The primary function of the DTSU666-HW is to accurately measure electrical parameters in three-phase four-wire or three-phase three-wire power grid systems. It can measure both positive and negative active energy, providing a comprehensive view of energy flow. Beyond energy, it also measures voltage, current, active power for each phase and total, and power factor for each phase and total. This detailed data is essential for energy auditing, load balancing, and identifying potential inefficiencies within an electrical installation.

The device supports various connection modes, making it adaptable to different current and voltage levels. For currents up to 80 A and line voltages up to 500 V, it can be directly connected to the system. When currents exceed 80 A or line voltages surpass 500 V, the DTSU666-HW integrates seamlessly with external current transformers (CTs) and potential transformers (PTs) to extend its measurement capabilities to higher-power environments. This flexibility ensures that the sensor can be deployed in a wide range of residential, commercial, and industrial applications.

Communication is a key aspect of the DTSU666-HW, facilitating data exchange with other devices in a monitoring system. It utilizes RS485 communication, allowing it to connect to data loggers like the SmartLogger or Smart Dongle. This enables remote monitoring, data collection, and integration into broader energy management platforms. The device supports various baud rates and communication protocols, ensuring compatibility with different system architectures.

Usage Features

The DTSU666-HW is designed for ease of installation and configuration. It is guide rail-mounted, specifically on a standard DIN35mm guide rail, which simplifies its physical integration into existing electrical panels. The installation process involves pressing the sensor onto the guide rail and sliding it into place, making it a quick and straightforward procedure.

Wiring scenarios are clearly defined, covering direct connections for lower power systems and transformer-based connections for higher power systems. The device provides distinct cable inlets and outlets for voltage, current transformer inputs, and RS485 communication, ensuring organized and correct wiring. Detailed instructions for connecting phase wires (UA, UB, UC, UN) and current transformer inputs (IA*, IA, IB*, IB, IC*, IC) are provided, along with guidelines for RS485 communication cables (RS485A, RS485B).

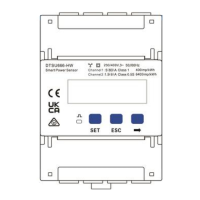

User interaction with the device is facilitated through a simple button interface and a display. The display allows users to view various measured parameters such as energy, voltage, current, and power. It also provides access to parameter settings, which are crucial for configuring the device according to the specific installation requirements. Parameters like current transformer ratio, potential transformer ratio, communication address, baud rate, wiring mode, rotation display time, and backlight illumination time can be adjusted.

The parameter setting operations are intuitive, using "SET" for confirmation or cursor movement, "ESC" for exiting, and "→" for adding. This allows users to easily navigate through menus and input values, such as the user password (default 701) for accessing protected settings. The ability to set the wiring mode (three-phase four-wire or three-phase three-wire) and channel switchover (direct connection or transformer connection) directly on the device ensures that it accurately reflects the physical installation.

Maintenance Features

The DTSU666-HW incorporates features that contribute to its reliability and ease of maintenance. Each phase of UA, UB, and UC in the Smart Power Sensor is equipped with a fuse and a thermistor. These components are designed to prevent damage caused by external short circuits, enhancing the device's durability and reducing the need for frequent replacements due to electrical faults. This internal protection means that external fuse protection for UA, UB, and UC is not required, simplifying the overall system design.

Troubleshooting guidance is provided to address common issues that may arise during installation or operation. For instance, if there is no display after power-on, the manual suggests checking cable connections and verifying that the supplied voltage is within specifications. In cases of abnormal RS485 communication, users are advised to check the communication cable for disconnections, short circuits, or reversed connections, and to ensure that the communication parameters (address, baud rate, data bit, parity bit) match those of the inverter.

For inaccurate metering, the guide recommends verifying the correctness of cable connections, especially the phase sequence of voltage and current. It also highlights the importance of correctly connecting the high and low ends of the current transformer inlet. If negative values are displayed for power (Pa, Pb, Pc), it indicates an incorrect connection of the CTs, and the manual instructs users to reverse the connections to correct the measurement.

Installation verification steps are also outlined, emphasizing the importance of securely installed mounting brackets and tightened screws. It also stresses the need to ensure that all cables are reliably connected with the correct polarity and without any short circuits, which are critical for safe and accurate operation. These guidelines help prevent common installation errors and ensure the long-term performance of the device.

The DTSU666-HW is designed with a focus on robust operation within specified environmental conditions, with an operating temperature range of -25°C to +60°C. This wide range allows for deployment in various climates without compromising performance. The device's certification (CE, RCM, and UKCA) further attests to its adherence to international safety and quality standards, providing assurance of its reliability and compliance.