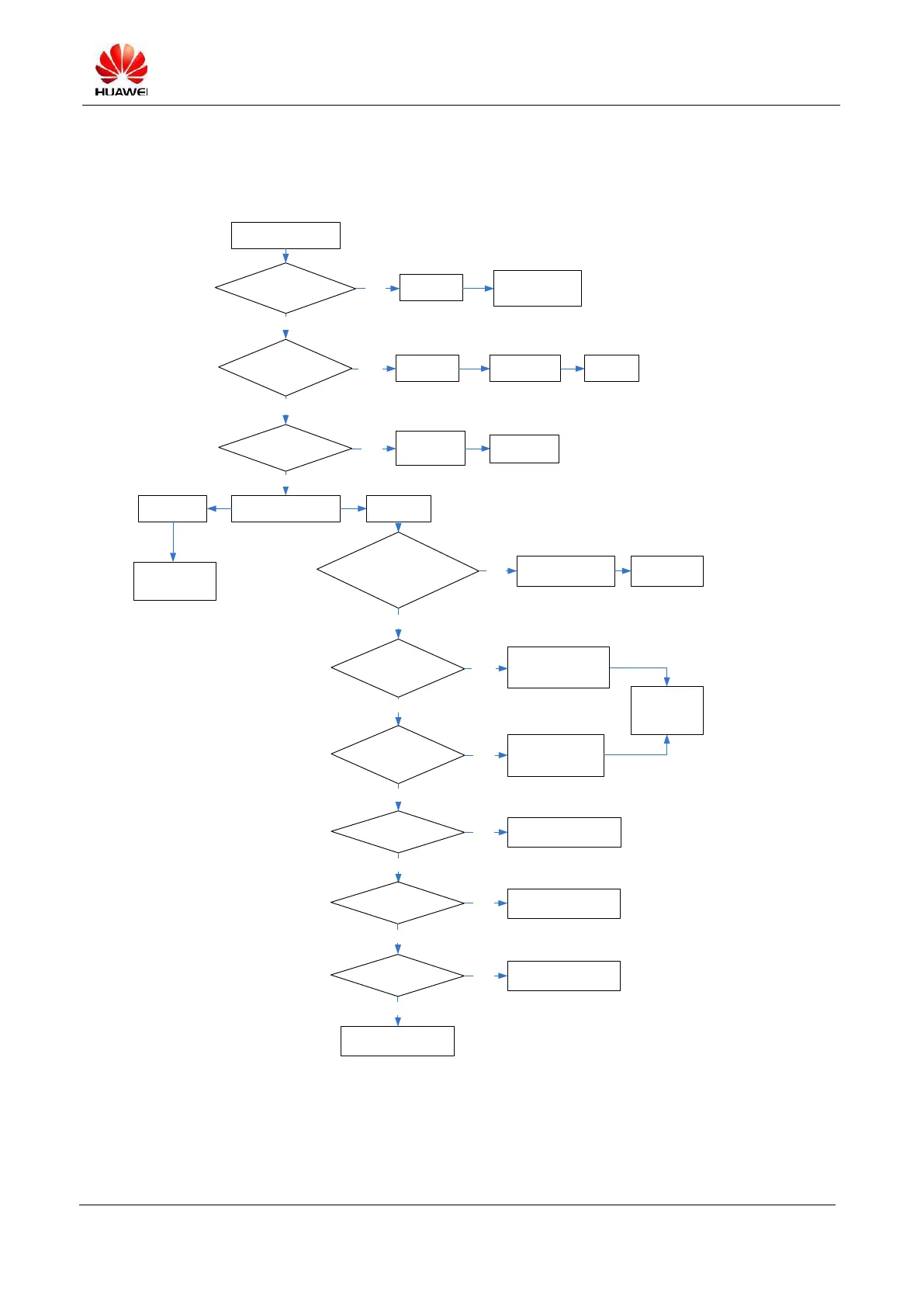

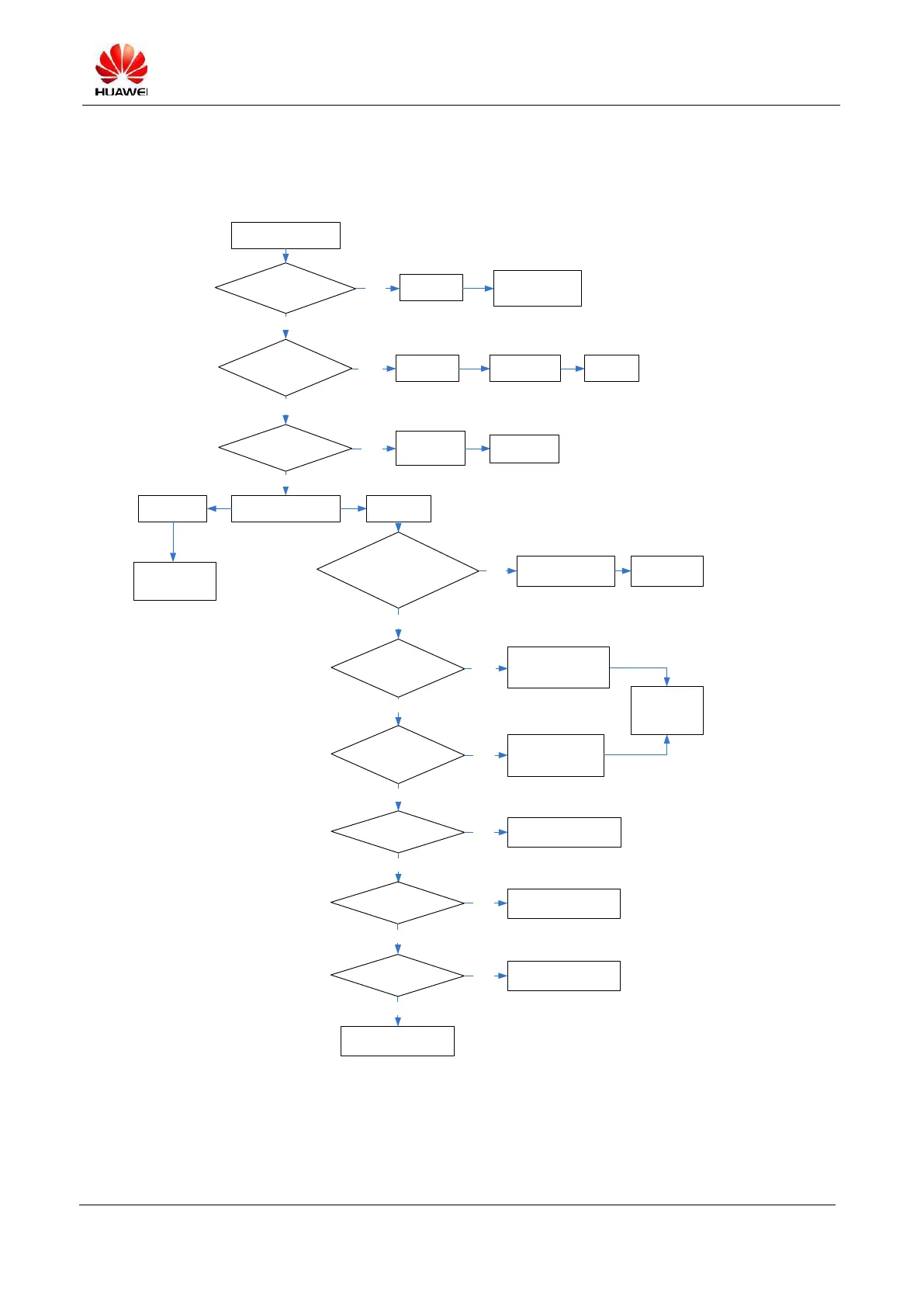

LCD failure

Test again and

re-debug the environment.

Does the failure recur?

Yes

Is there any

cosmetic defect (such

as spot defects, black

spots,

and damage)?

Is the LCD

BTB connector

fastened properly?

No

Yes

Perform cross

verification for the LCD

and PCBA

The LCD is

faulty

The PCBA is

faulty

Replace the LCD

and ask the MQE

to analyze the

faulty LCD

No

NTF

Report to the TE

and equipment

engineers for cause

analysis

Yes

The IPQC re-

checks the

failure

The PQE re-

checks the

failure

Replace the

LCD

No

The PQE

analyzes the

cause to

prevent

assembly risks

Re-assemble

the LCD

Check the

appearance. Use an X-ray

machine to check the PCBA.

Are there any soldering issues

on the PCBA, especially on the

BTB

connectors?

Ye

s

No

Is the voltage

of the LCD backlight

LED indicator normal

(LB1704~LB1707)?

Is the LCD

driver voltage normal

(LB1701、LB1702)?

Is the

LCD I/O power VDDIO

normal (C1027)?

Ye

s

No

If there are no soldering

issues, replace defective

components

No

Check whether

U1702 and peripheral

small components are

defective

If there are no

soldering

issues, replace

defective

components

Check whether U1701

and peripheral small

components are

defective

No

The PCBA process

engineers analyze the

cause

Repair the area

with soldering

issues

Ye

s

Ye

s

Is the

RST PWM TE signal

normal (R1723、

R1724、R1721)?

Ye

s

No

If there are no soldering

issues, replace defective

components

Is the

MIPI signal normal

(T1701~T1705)?

Ye

s

No

If there are no soldering

issues, replace defective

components

Replace U300

Loading...

Loading...