10

2624 & 2630 Series Hydraulic Installation Tools (HK1052) Alcoa Fastening Systems & Rings

NOTE: When reassembling the tool, always replace damaged

and defecve parts, and all seals, wipers, O-rings, and Back-up

rings of subassemblies. Prior to reassembling the tool, HUCK

recommends having the following items accessible.

• The appropriate Huck Spare Parts Service Kit: P/N 2624KIT

(2624, 2624-15), P/N 2624HSKIT (2624HS, 2624-PT,

2624PTD), or P/N 2630KIT (2630, 2630RR)

• LUBRIPLATE® 130-AA (available as P/N 502723) or SUPER-O-

Lube® (available as P/N 505476)

BEFORE ASSEMBLING THE TOOL:

• Clean components in mineral spirits or other solvent

compable with O-ring seals.

• Clean out O-ring grooves.

• Inspect components for scoring, excessive wear, and

damage; replace as necessary.

• Replace O-rings and Back-up rings. See Assembly Drawings

for guidance on posioning these rings.

When assembling the tool, take care not to damage O-rings,

Quad-rings, Back-up rings.

• Smear LUBRIPLATE® 130-AA or SUPER-O-LUBE® on rings

and mang parts to ease assembly.

TO ASSEMBLE THE TOOL:

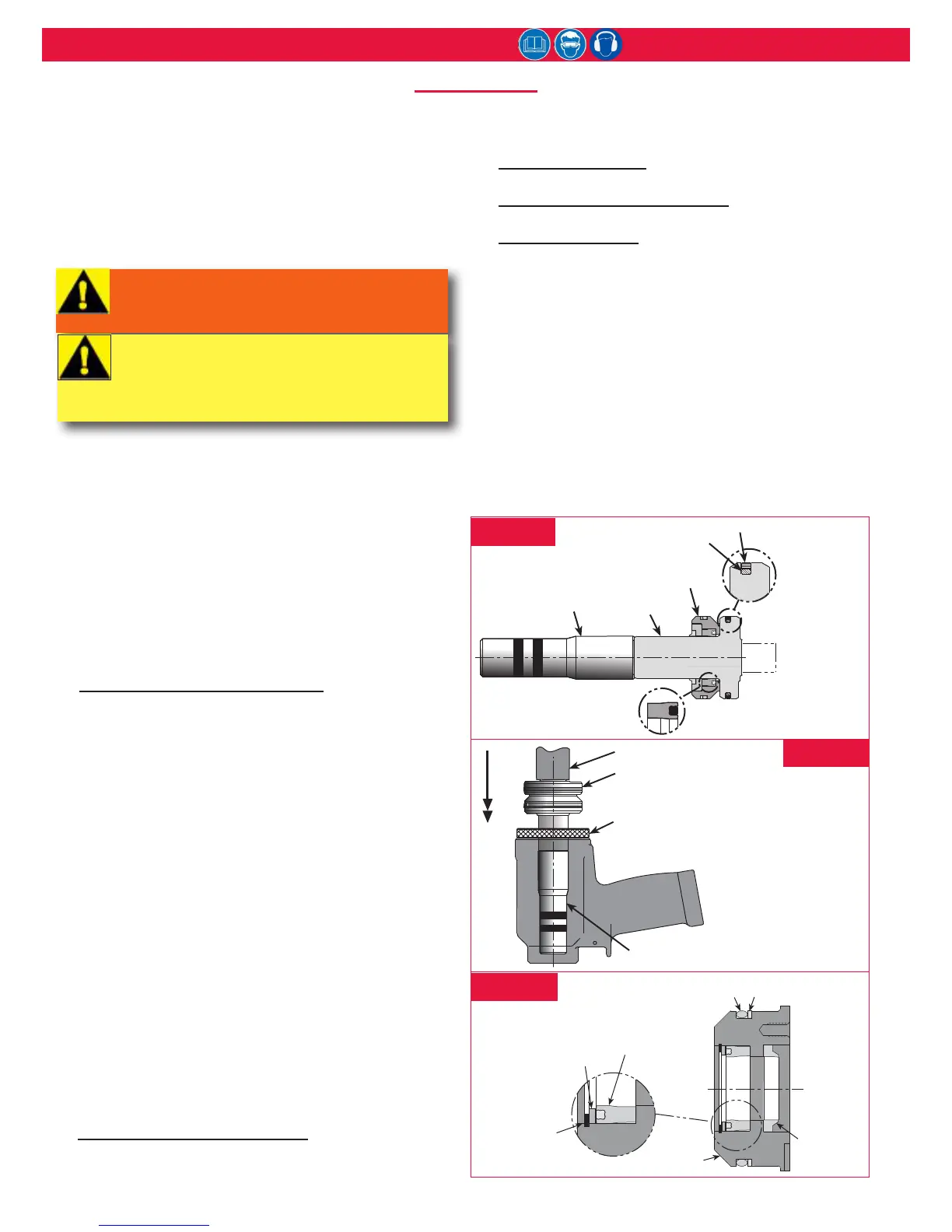

1. Assemble all seals,

washers, wipers, rings, and ejector rod into ejector gland/

cartridge. Hold the piston in a vise with so jaws and

install assembled ejector gland/cartridge assembly. Use

hex key (P/N 122048) to ghten.

2. Thread the Piston Assembly Tool and GLYD ring onto the

piston (Figure 5). NOTE: Do not install the spacer. The

spacer is only used during disassembly procedure, as it

assists in pushing out the front gland assembly along

with the piston.

3. Install Polyseal, O-ring, Back-up ring, wiper housing, and

wiper into front gland. (Figure 5)

4. Lubricate the piston assembly tool and the piston; then

slide the assembled gland over the piston assembly tool

onto the piston. (Figure 5)

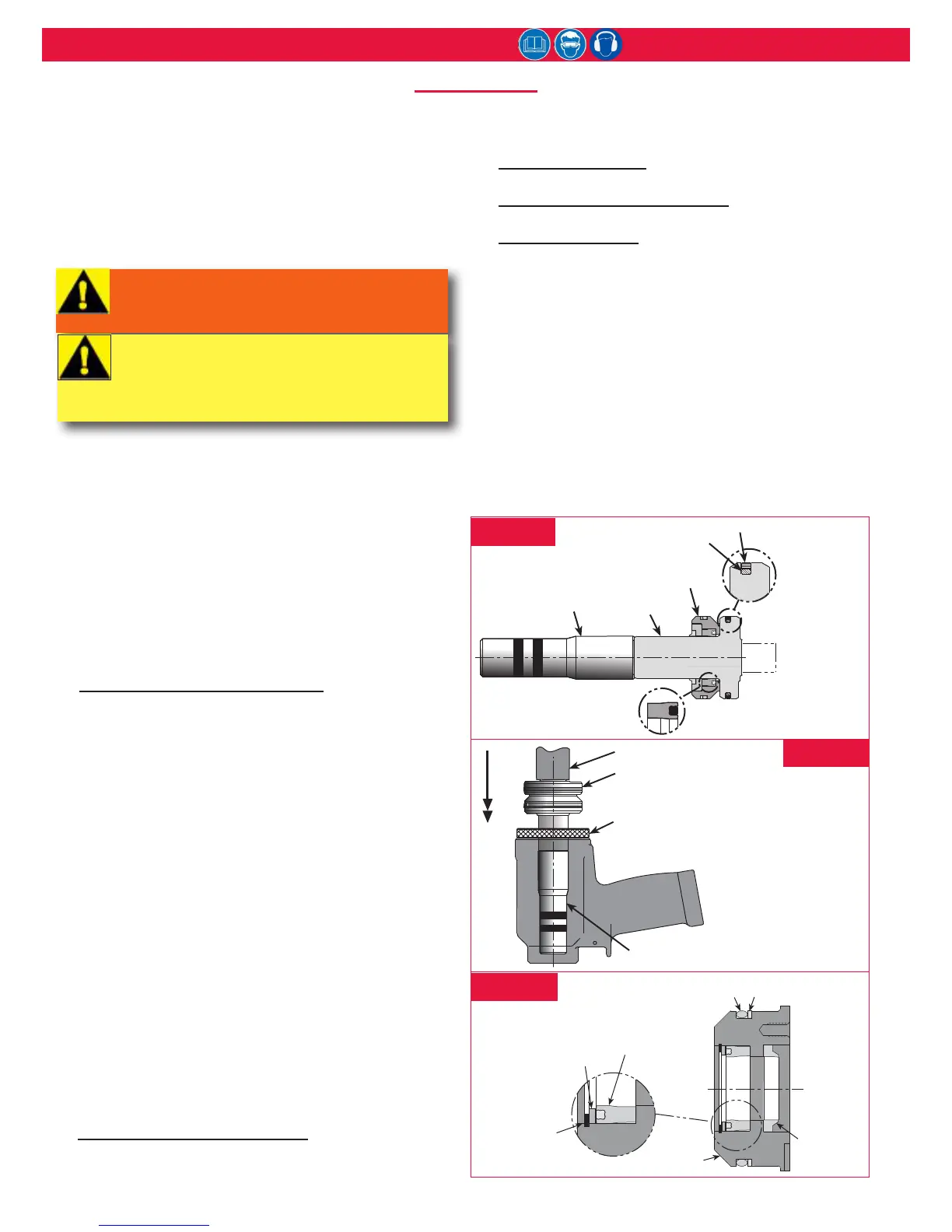

5. Thread the piston inseron tool into the back of the

cylinder. (Figure 6)

6. Using a press, push the piston and front gland assembly

into the back of the cylinder. (Figure 6)

7. Remove the piston assembly tool from the front of the

cylinder, and the piston inseron tool from the rear of it.

8. At the rear of the cylinder, install the dump valve (Figure

8) with the four ats facing the rear of the tool.

9. Install O-ring and Back-up ring on the end cap.

Install Back-up ring,

O-ring, wiper seal, Polyseal, washer, and retaining ring into

the end cap. (Figure 7)

10. Insert the hex key into the end cap. Use a wrench to

thread the end cap into the back of the cylinder and

ghten. (Figure 2)

11. Install locking disk, cover plate,

and retaining ring. (Figure 8)

Install locking disk,

retainer, and screws. (Fig. 9); 2624PTD see Fig. 10

: Install locking disk, clamshell

retainer assembly, and retaining ring. (Figure 11)

• If removed during disassembly, reinstall the electrical

connector. If the switch or wire was removed, replace

as follows: Slide the retaining nut and ferrule onto the

electrical wire. Feed the wire through the handle and pull

out through the trigger switch hole. Aach the wires to

trigger switch and push assembly back into the handle.

Tighten the setscrew to hold trigger switch in place. Slide

ferrule into the strain relief housing, then thread and

ghten the retaining nut.

• If removed during disassembly, install one hydraulic hose in

handle port marked “P” and one in port marked “R“.

• Install coupler nipple 110438 on PULL pressure side and

coupler body 110439 on RETURN pressure side of hoses.

asseMbly

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

2624HS

2624-PT

Piston

“special” O-Ring

123111-7 (2624 series)

123111-9 (2630 series)

fIgure 5

fIgure 6

WARNING: Do not omit any seals during

servicing; leaks will result and serious

personal injury can occur.

CAUTION: Do not use TEFLON

®

tape on

pipe threads. Tape can shred, resulting in

malfunctions. Apply Parker Threadmate,

Loctite 567, or Slic-tite stick to male pipe

threads per manufacturer’s instructions.

fIgure 7

Loading...

Loading...