7

2624 & 2630 Series Hydraulic Installation Tools (HK1052) Alcoa Fastening Systems & Rings

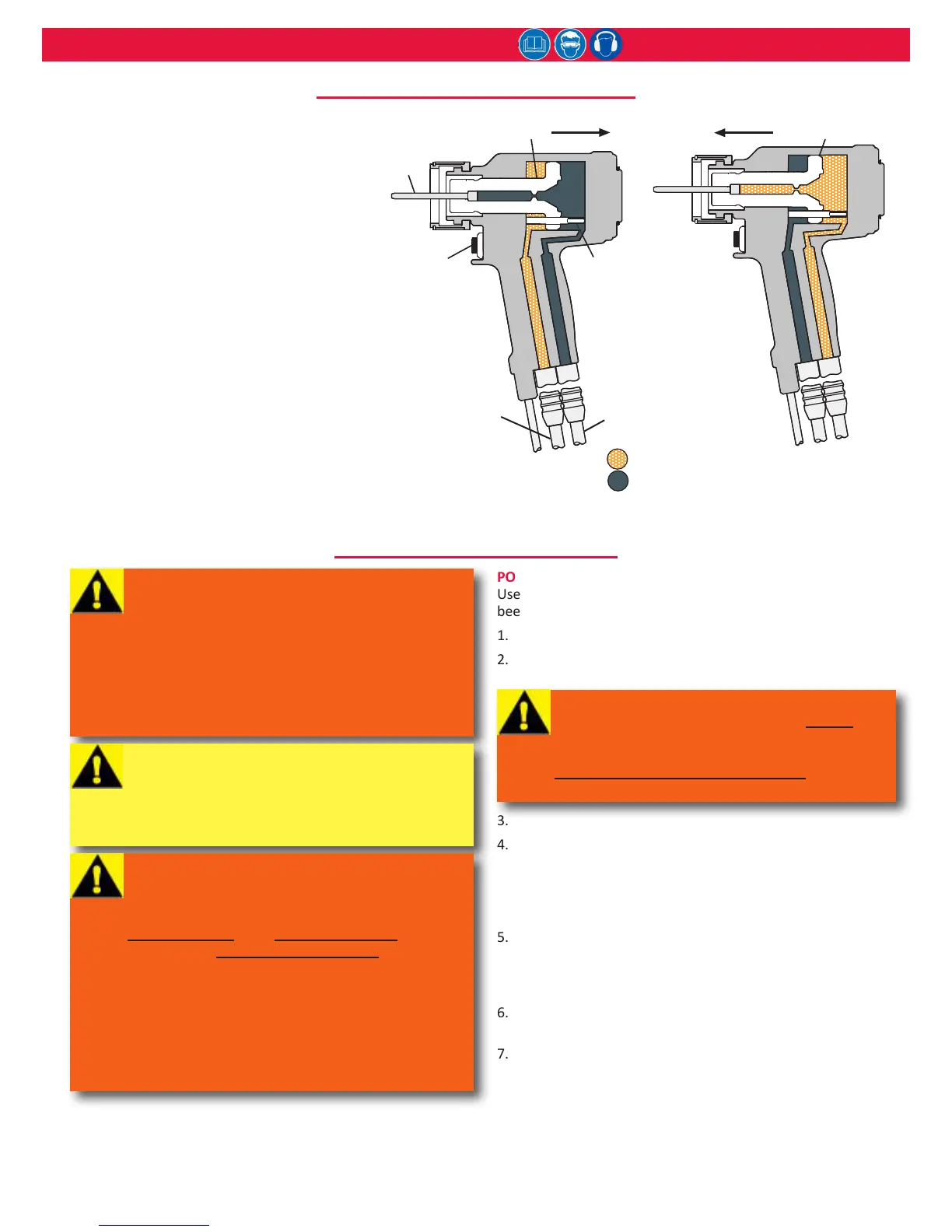

When the trigger is pressed, a solenoid-

operated valve in the POWERIG

®

directs

pressurized uid through the PULL hose to the

front side of the piston; uid on the RETURN

side ows back to the tank (Fig 1a). The piston

and nose assembly collet move rearward,

installing the fastener. When the piston

reaches the end of the PULL stroke, it uncovers

ats on the rear end of the dump valve. This

provides a passage for uid from the PULL side

to the RETURN side of the piston, “dumping”

the pressurized uid back to the tank (Fig 1a).

When the trigger is released, the solenoid is

de-energized and the valve directs pressurized

uid to the rear of the piston; uid on the

PULL side ows back to the tank (Fig. 1b). The

piston and collet move forward, and push

the nose assembly and tool o the installed

fastener. When the piston reaches the end of

the RETURN stroke, pressure builds, causing

the POWERIG to shut o, compleng the cycle.

prInCIple of operatIon

Threadmate is a registered trademark of Parker Intangibles LLC.

is a registered trademark of E. I. du Pont de Nemours and Co.

is a registered trademark of Henkel Corporaon, U.S.A.

is a registered trademark of LA-CO Industries, Inc.

POWER SOURCE CONNECTIONS

Use a Huck Powerig Hydraulic Unit, or equivalent, that has

been suitably prepared for operaon.

1. Turn OFF the Powerig and disconnect its power supply.

2. Coat the tool’s hose-ng threads with Locte

®

243

™

or

equivalent, and then connect the hoses to the Powerig.

3. Connect the tool’s control switch cord to the Powerig.

4. Connect the Powerig to the power supply and turn it ON.

Press and hold the tool trigger for 30 seconds; then press

trigger a few mes to cycle the tool and circulate the

hydraulic uid. Observe the acon of the tool and check

for leaks. Turn OFF the Powerig.

5. Disconnect tool’s control switch cord from the Powerig;

disconnect the Powerig from the power supply. Select a

nose assembly for the fastener to be installed and aach

it to the tool.

6. Reconnect the Powerig to the power supply and the

tool’s switch control cord to the Powerig.

7. Check the operaon of nose assembly; install fasteners

in a test plate of correct thickness with proper size holes.

Inspect installed fasteners.

NOTE: If fasteners do not pass inspecon, see

to invesgate possible causes.

preparatIon for use

WARNING:

Read entire manual before using tool.

A 30-minute training session with qualied

personnel is recommended before using Huck

equipment.

When operating Huck equipment, always wear

approved eye and hearing protection.

Be sure there is adequate clearance for the

operator’s hands before proceeding.

WARNING: Be sure to connect the tool’s

hydraulic hoses to the POWERIG before

connecting tool’s switch-control cord to the

POWERIG. If not connected in this order and

disconnected in the reverse order, severe

personal injury may occur.

CAUTION: Keep disconnected hoses and

couplers and hydraulic uid free of foreign

matter. Contaminated uid can cause valve

failures. Apply Parker Threadmate, Loctite

567, or Slic-tite stick to male pipe threads per

manufacturer’s instructions.

WARNING: Huck recommends that Huck

POWERIGS be used to power Huck tools.

Hydraulic power units that deliver high PULL

and RETURN pressures—but which are

NOT equipped with RELIEF VALVES—are

specically NOT RECOMMENDED and may be

dangerous.

Set the PULL and RETURN pressures as

specied in sPecIfIcatIons. Failure to properly

set these pressures may result in serious

personal injury.

Huck Pressure Gauge (P/N T-124883CE) is

available, and should be used as indicated in

its instruction manual.

Loading...

Loading...