9

2624 & 2630 Series Hydraulic Installation Tools (HK1052) Alcoa Fastening Systems & Rings

dIsasseMbly

This procedure is for complete disassembly of the tool.

Disassemble those components necessary to replace

damaged rings and worn or damaged components. Always

use a so-jaw vise to avoid damaging the tool.

1. Disconnect electrical or air connector from Powerig

®

.

Uncouple tool hydraulic hoses.

2. Remove nose assembly.

3. Unscrew coupling nipple and coupling body. Drain

hydraulic hoses into container. Discard uid.

4. Push rearward on Piston unl remaining hydraulic uid is

drained into container. Discard uid.

NOTE: Do not remove hydraulic hoses from the tool unless

replacing the hoses. If it is necessary to remove hoses,

uncover the hose ngs by sliding back the plasc shrouds.

5. Use these steps only if the switch, wire, or electrical

connector needs repair. Remove retaining nut and locking

ferrule from strain relief. Loosen setscrew. Remove

trigger switch. Loosen and remove the two wires from

the switch. Remove cord from tool. Disassemble electrical

connector (P/N 110686).

6. Models 2624, 2624-15: Remove end cap retaining ring,

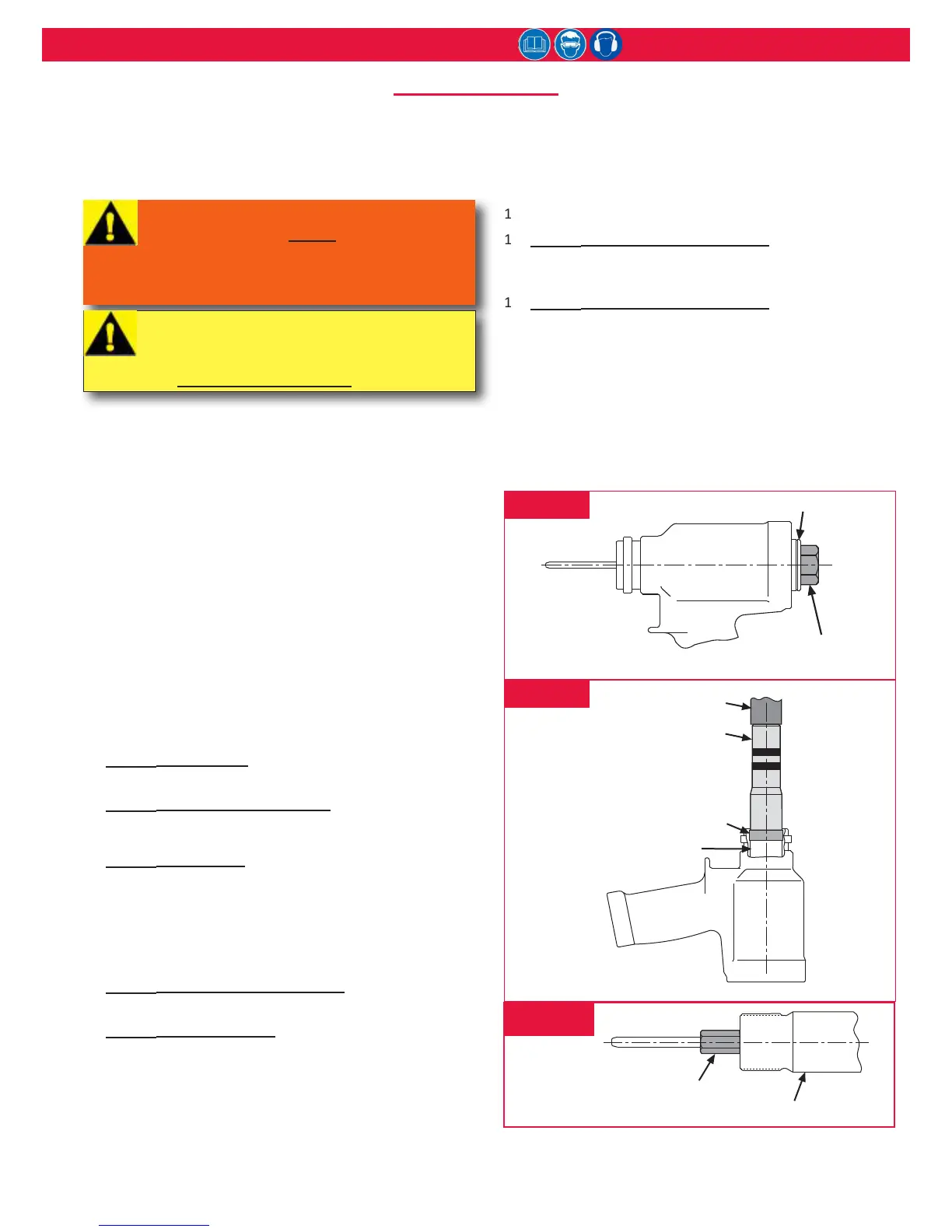

cover plate, and locking disk. (Figure 8)

Models 2624HS, 2624-PT, 2624PTD: Remove screws,

retainer, deector (2624PTD), and locking disk. (Figures 9

& 10)

Models 2630, 2630RR: Remove retaining ring from rear

of tool; then remove clamshell retainer assembly and

locking disk. (Figure 11)

7. Insert hex key (P/N 126981, shipped with tool) into end

cap. (Figure 2) Using a wrench, unscrew the end cap from

the cylinder.

8. Models 2624, 2624-15, 2630, 2630RR: Remove the O-ring

and Back-up ring from end cap.

Models 2624HS, 2624-PTD: Remove the O-ring and Back-

up ring from front gland, and retaining ring, washer,

polyseal, and wiper seal from end cap.

9. Remove the dump valve from rear of cylinder.

10. Slide spacer over piston and thread Piston Assembly Tool

onto front of piston. Using a press, push front gland and

piston assemblies out the rear of the cylinder. (Figure 3)

11. Remove Piston Assembly Tool and spacer.

12. Slide front gland o of piston. Remove wiper, wiper

housing, Back-up ring, O-ring, and Polyseal from front

gland.

13. Remove the GLYD ring from the piston. (Figure 5)

14. Models 2624, 2624-15, 2630, 2630RR: Hold piston in a

vise and remove ejector gland/cartridge assembly with

hex key (P/N 122048). (Figure 4)

15. Models 2624, 2624-15, 2630, 2630RR: Remove ejector

rod, wiper, and all seals from gland/cartridge.

The tool has been properly disassembled. Store all re-usable

parts (screws and disassembled components) in a clean, dry

area.

fIgure 3

fIgure 4

fIgure 2

WARNING: Disconnect the tool control cord

from the POWERIG before disconnecting

the hydraulic hoses from it.

If not disconnected in this order, serious

personal injury may occur.

CAUTION: Do not re-use seals, wipers, or

rings; irreparable tool damage could occur.

Discard these parts and use replacements

(see sPare Parts servIce KIts).

Loading...

Loading...