507

HYDRAULIC INSTALLATION TOOL

(HK480)

WARNING: Huck recommends that only

Huck Powerig Hydraulic Units be used

as a power source for Huck installation

equipment. Hydraulic power units that

deliver high pressure for both PULL and

RETURN, AND ARE NOT EQUIPPED

WITH RELIEF VALVES ARE SPECIFICAL-

LY NOT RECOMMENDED AND MAY BE

DANGEROUS.

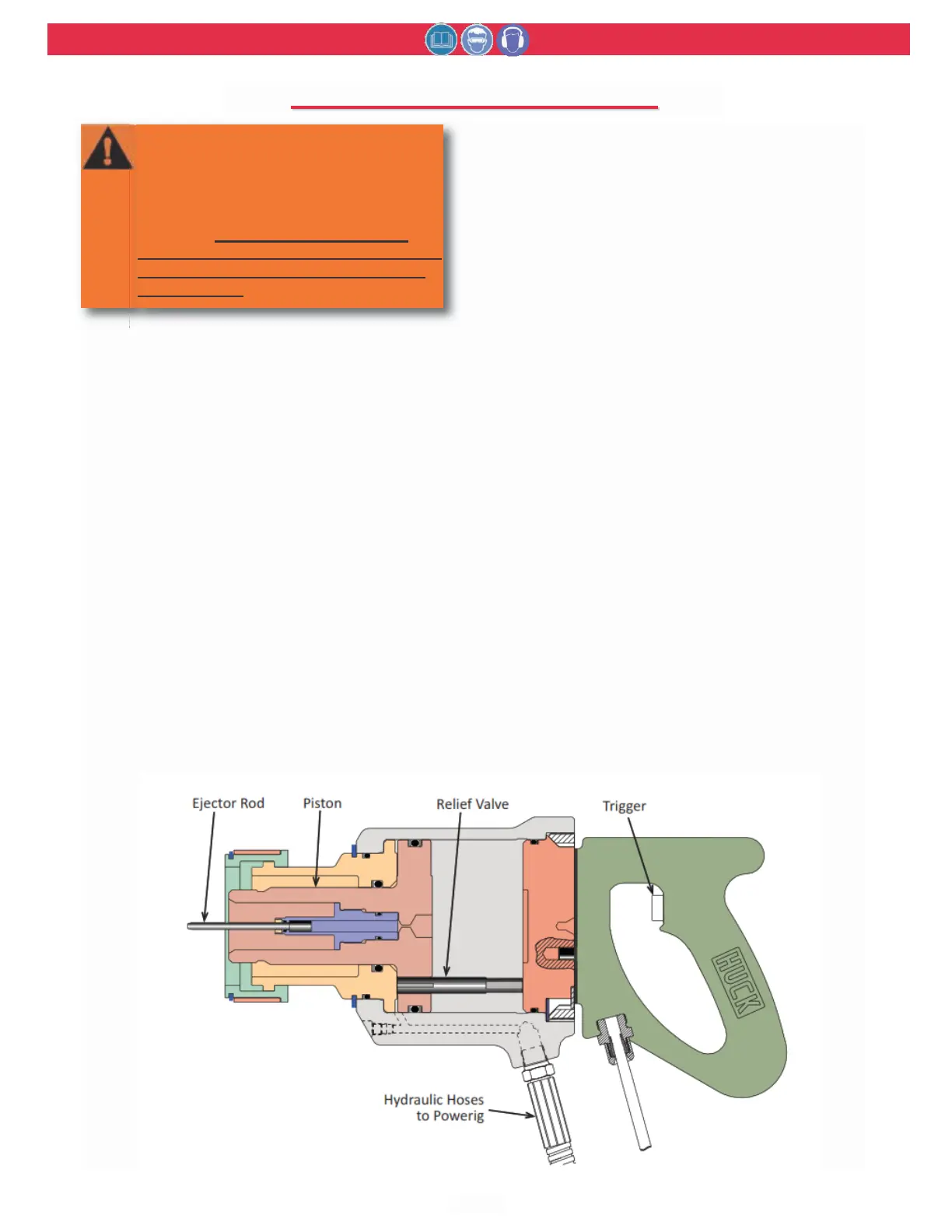

When tool hoses and cord are connected to Powerig hoses

and control cord, PULL and RETURN strokes of tool are con‐

trolled by a Trigger in the handle.

When the trigger is depressed, a solenoid operated valve in

the POWERIG directs pressured fluid through the FILL

Hydraulic Hose to the front side of piston, and allows fluid

on the RETURN side to flow back to tank.

The piston and nose assembly collet moves rearward caus‐

ing follower O‐rings and/or spring to impart a forward

motion to the follower.

If tool and nose assembly is in position on a fastener pin

and collar, this forward motion causes the jaws to clamp

onto pintail of fastener and installation cycle commences.

Clamping pressure is applied to the sheets. The anvil is

forced forward, swaging the collar into locking grooves of

the fastener.

When the anvil hits the sheet, continued pull causes the

pintail to break off. When the Piston reaches the end of its

PULL stroke, it uncovers flats on the rear end of the Relief

Valve. These flats were designed to provide a passage for

hydraulic fluid from PULL side to RETURN side of piston,

“unloading” or “dumping” the pressurized fluid back to

tank.

When the trigger is released, the solenoid is de‐energized

and the valve directs pressurized fluid to rear side of the

piston and allows fluid on PULL side to flow back to tank.

This causes piston and collet to move forward and pushes

nose assembly and tool off the swaged (installed) fastener.

Nose assembly jaw release contacts jaws, causing them to

open and release the broken‐off pintail. The Ejector Rod

hydraulically ejects the pintail out the front of the nose

assembly. When the piston reaches the end of its RETURN

stroke, pressure is built up causing the Powerig idler valve

(except on Models 910 and 911) to go to idling pressure.

Idling pressure keeps the tool piston and nose assembly

collet, jaws, etc. in the forward position ready for the next

installation cycle.

A flat on the front end of the relief valve was designed to

provide a passage for hydraulic fluid from RETURN side of

piston to PULL side of piston and back to tank.

Loading...

Loading...