10

amount of concrete used to form the pad should exceed

the weight of the compressor by 3 to 5 times. SAE Gr.

5 “J” bolting of appropriate length and size should be

used in the pad to provide baseplate mounting. Use of

a template to support and position the bolting +/– 1/16”

while setting concrete is recommended. Securing

bolting to existing foundations with drilled holes and

adhesives is not recommended unless expert advice

is available. Expert advice is also recommended for

installation of other forms of mechanical anchors. See

Figure 3 for additional details.

Epoxy based grouting is required to firmly seat

and attach the compressor skid to the concrete

foundation. ITW Philadelphia Resins brand “Chockfast

Red” grout is recommended. Sealing of grouts and

concrete is recommended to prevent contamination

by oil and moisture. Newly poured concrete must be

fully hydrated prior to grouting. The concrete slab

should be chipped to remove all latent and 50% of

the aggregate exposed to provide a rough bonding

surface for the epoxy. Dowels should be installed on

new exposed concrete to prevent edge lifting. The

concrete foundation should be dry and free of oil before

pouring grout. Sleeve all foundation bolts to prevent

adhesion and allow bolt stretch. Steel baseplates

should be sanded and cleaned to provide adequate

adhesion surface.

Steel fabricated foundations must be adequately

engineered to support the weight and vibration of the

compressor.

INLET PIPING & INLET FILTRATION

Compressor life can be substantially increased by

providing clean, dry, cool gas to the compressor

inlet.

Ambient Air Compressors – In most cases,

the standard air fi lter furnished from the factory is

suffi ciently large to meet normal operating conditions

when periodically serviced. Where the compressor

inlet is to be piped to the outside, a hood or shroud

must be installed to prevent rain from entering the fi lter

or pipe. In severe environmental conditions, it may

be necessary to consider a non-standard inlet fi lter.

Contact the factory for assistance in this case.

Large runs of intake piping require an increase in

piping size to maintain compressor effi ciency; pipe

size should be increased one size for each 10 feet of

intake pipe and each 90° bend.

Air Boosters & Gas Compressors – The inlet piping

may be at a pressure above atmospheric, and must

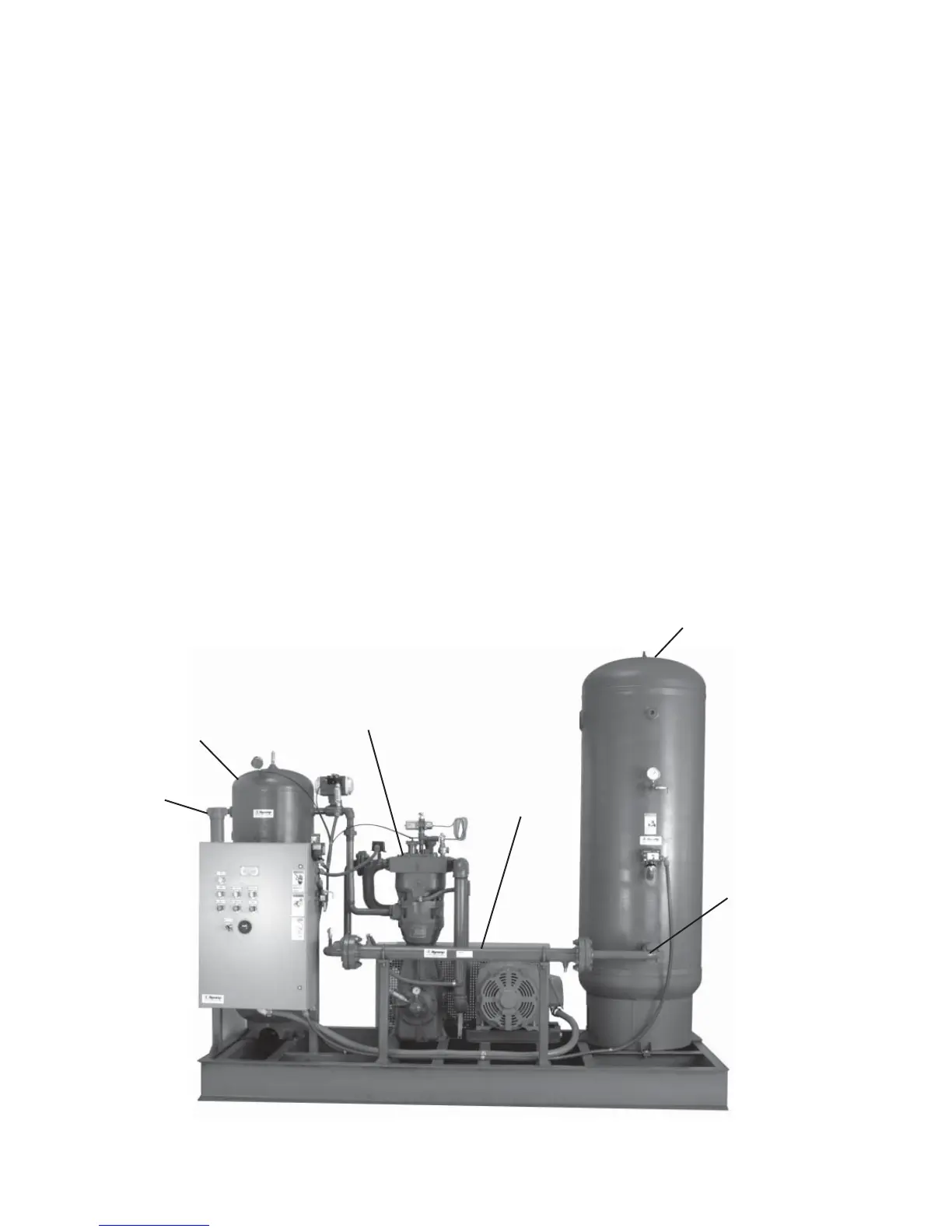

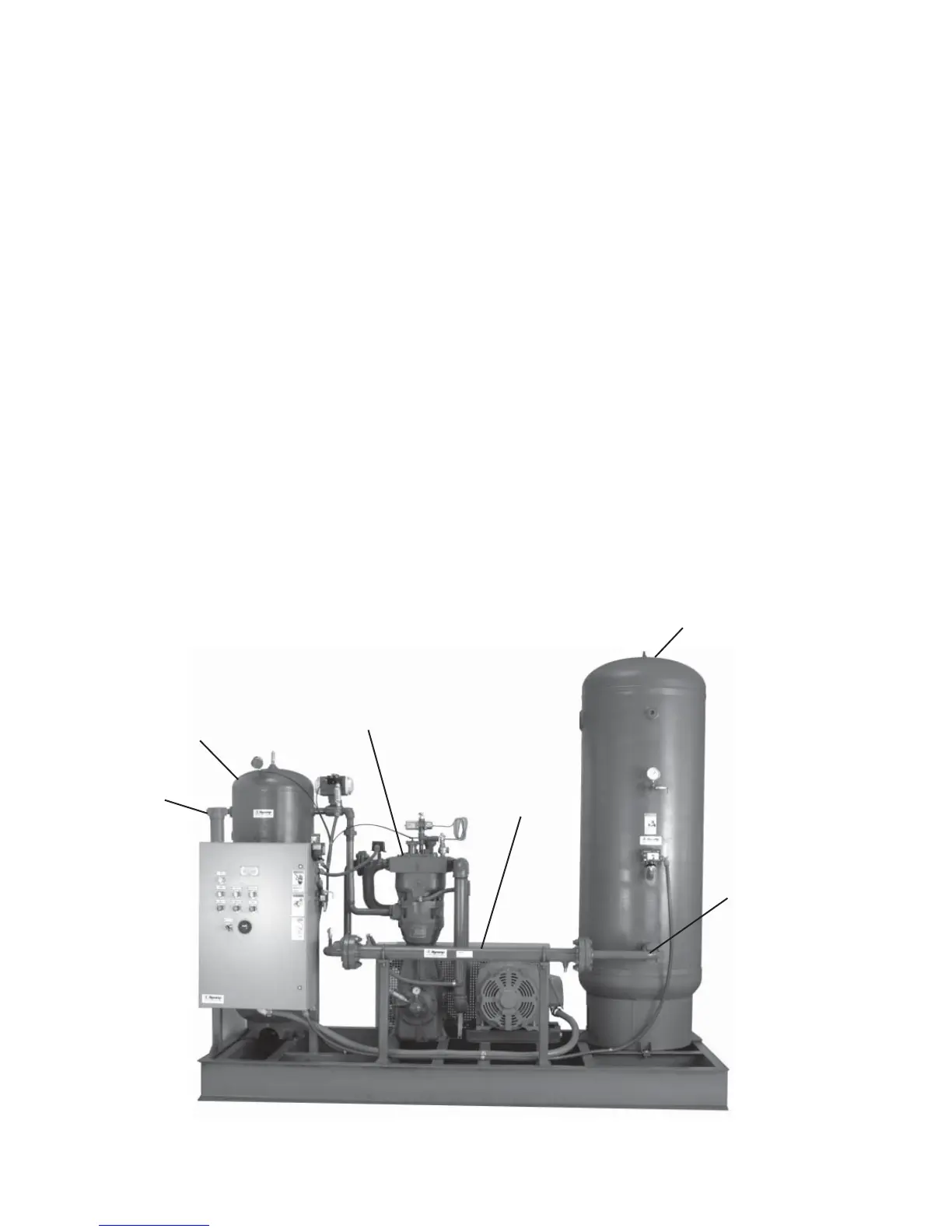

Inlet Receiver

Inlet Filter

(required on all

applications)

Hycomp Booster

Compressor

Discharge Receiver

Discharge

Check Valve

(required on all

applications)

Aftercooler

Figure 4: Basic System Confi guration of an Air Booster or Gas Compressor

Loading...

Loading...