42

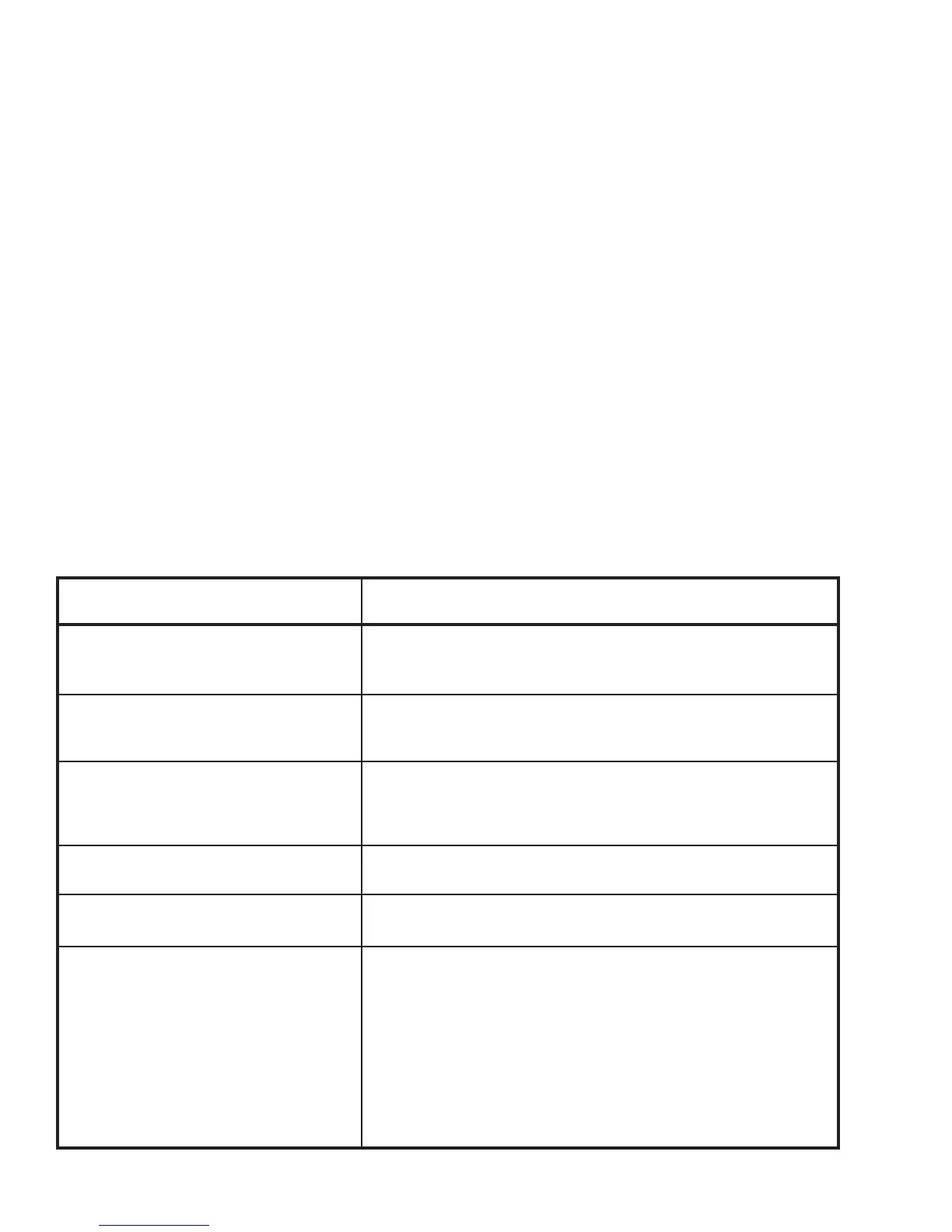

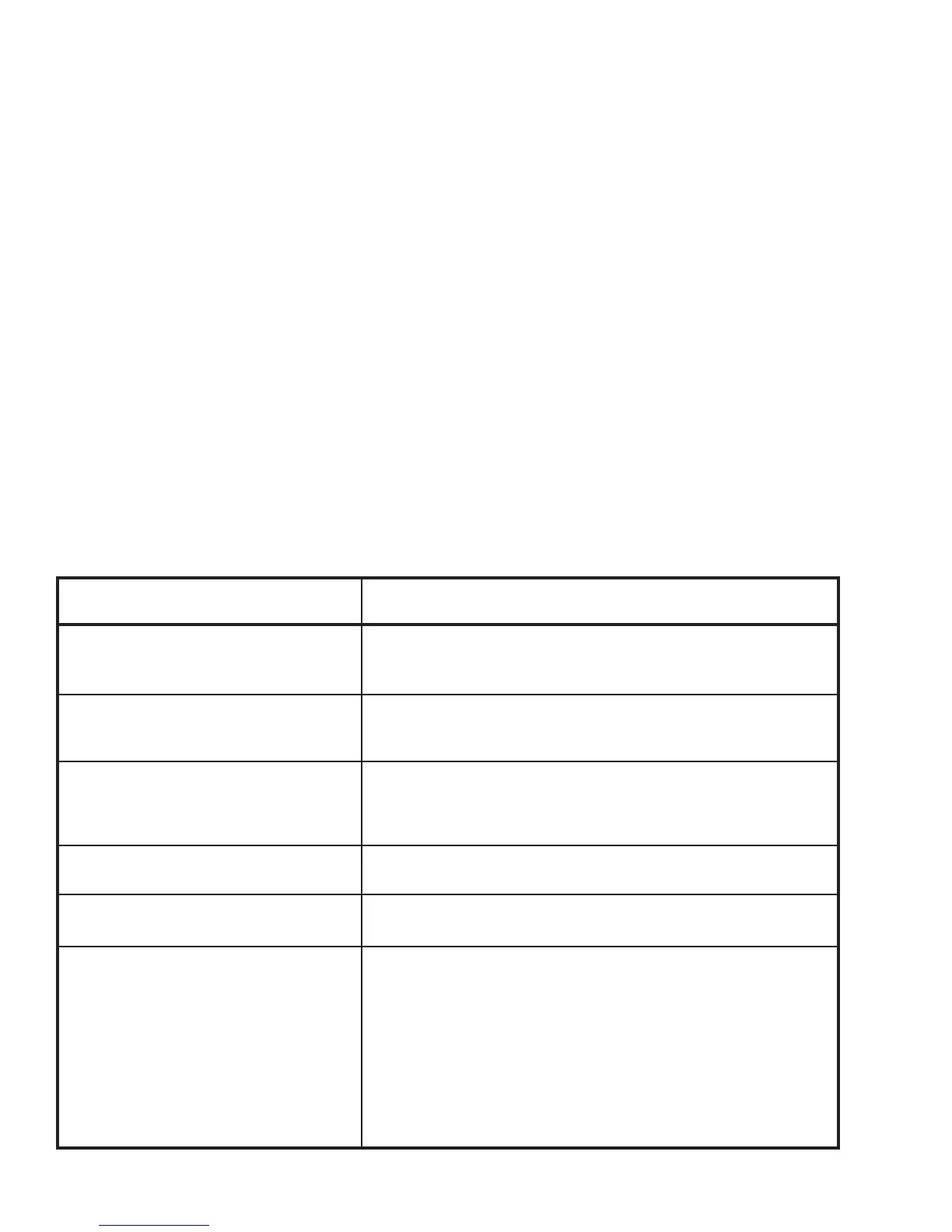

PROBABLE CAUSE

AIR LEAKS

LEAKING VALVES

PISTON RING NOT SEALING

RESTRICTED AIR INLET

BLOWN GASKETS

VALVE UNLOADERS NOT FUNCTIONING

PROPERLY

SUGGESTED REMEDY

LOCATE AIR LEAKS BY SOUND OR SOAP BUBBLE TEST. TIGHTEN

OR REPLACE LEAKING FITTINGS ONLY AFTER REDUCING AIR

PRESSURE TO ZERO.

REMOVE VALVES AND INSPECT FOR DAMAGE TO VALVE SEAT OR

VALVE DISC. REPLACE SUSPECT COMPONENTS AND REINSTALL

VALVES USING NEW VALVE SEAT GASKETS AND COVER GASKETS.

REMOVE PISTON RINGS AND CHECK FOR WEAR. IF RING

THICKNESS HAS BEEN REDUCED TO 3/16 INCH OR LESS AT ANY

SPOT, THE RINGS SHOULD BE REPLACED. DO NOT BORE OR

HONE THE CYLINDER UNLESS IT IS BADLY SCORED OR PITTED.

REPLACE THE AIR FILTER ELEMENT. CHECK FOR ANY

OBSTRUCTIONS IN INLET AIR PIPING.

CHECK CYLINDER HEAD AND VALVE GASKETS - REPLACE AS

NECESSARY.

WITH THE COMPRESSOR RUNNING, DISCONNECT THE TUBING

TO THE VALVE UNLOADER ON THE CYLINDER HEAD. IF AIR DOES

NOT ESCAPE, BUT THE COMPRESSOR CONTINUES TO RUN

PARTIALLY OR COMPLETELY UNLOADED, REMOVE THE UNLOADER

ASSEMBLIES AND VALVES AND INSPECT. IF AIR DOES ESCAPE

FROM THE DISCONNECTED TUBING WITH THE COMPRESSOR

RUNNING CHECK FOR LOW OIL PRESSURE. IF AIR ESCAPES BUT

OIL PRESSURE IS NORMAL, REMOVE THE HYDRAULIC UNLOADER

AND PILOT VALVE AND CHECK THEIR VALVE SEATS. IT IS NORMAL

FOR AIR TO LEAK FROM THE DISCONNECTED TUBE WHEN THE

COMPRESSOR IS STOPPED IF A HYDRAULIC UNLOADER IS USED.

TOUBLESHOOTING CHART

INSUFFICIENT AIR PRESSURE OR VOLUME

TROUBLESHOOTING

WARNING: The compressor MUST be locked out

from all energy sources prior to inspection, and

all pressure MUST be relieved from unit to prevent

unexpected release.

There are times when any compressor, no matter how

well built and how accurately maintained, will exhibit

some trouble. While Hycomp engineers are available

to assist any customer experiencing compressor

diffi culties, the following tables are provided to assist

with initial diagnostics.

Find the section describing the general problem

exhibited, then check the probable cause.

If it is not possible to diagnose the cause of the

problem, contact Hycomp or a Hycomp authorized

dealer for assistance.

The only additional problem encountered with the

gas compressors is excess loss of gas through the

packings. Generally the problem is caused by improper

maintenance of the gas packings. However, if the gas

packings have been well maintained, and leaks still

persist, contact the factory.

Loading...

Loading...