13

Discharge Pressure Switch with

Adjustable Deadband (connect to

discharge pressure receiver)

Suction Pressure Switch

with Fixed Deadband (connect

to suction pressure receiver)

3-Way Unloader Control Solenoid (connect to

pressure source at least 30 psig above suction

pressure - See Unloading Plumbing Instructions)

in the water temperature through the compressor.

A visual fl ow indicating device is highly recommended

at one or more locations on the coolant inlet and/or

discharge lines. Check discharge coolant piping

backpressure. Excessive backpressure will result in

the compressor overheating. Compressors exposed

to sub-freezing temperatures must be protected from

damage caused by coolant freezing.

Hycomp recommends the use of the following valves

and devices to regulate cooling water:

Solenoid Shutoff Valve – Solenoid actuated valves

control the flow of water through the compressor

system, preventing fl ow at start-up, during shutdown,

or between compressor cycle times.

Thermoregulating Valve – Modulating valves regulate

the fl ow of water to the compressor to maintain a desired

exiting water temperature. They open automatically

when temperature increases at the sensing bulb. No

external power source is required to actuate the valve.

The sensing bulb should be placed in the discharge

water stream, while the main valve body should be

placed in front of the compressor.

Visual Flow Indicator – Flow indicators display to

the operator when there is water fl ow through the

compressor. On large scale water tower systems,

backpressures within the system can prevent water

fl ow through the compressor, causing overheating and/

or freezing problems. A well monitored fl ow indicator

can assure the user that water is fl owing properly

through the system.

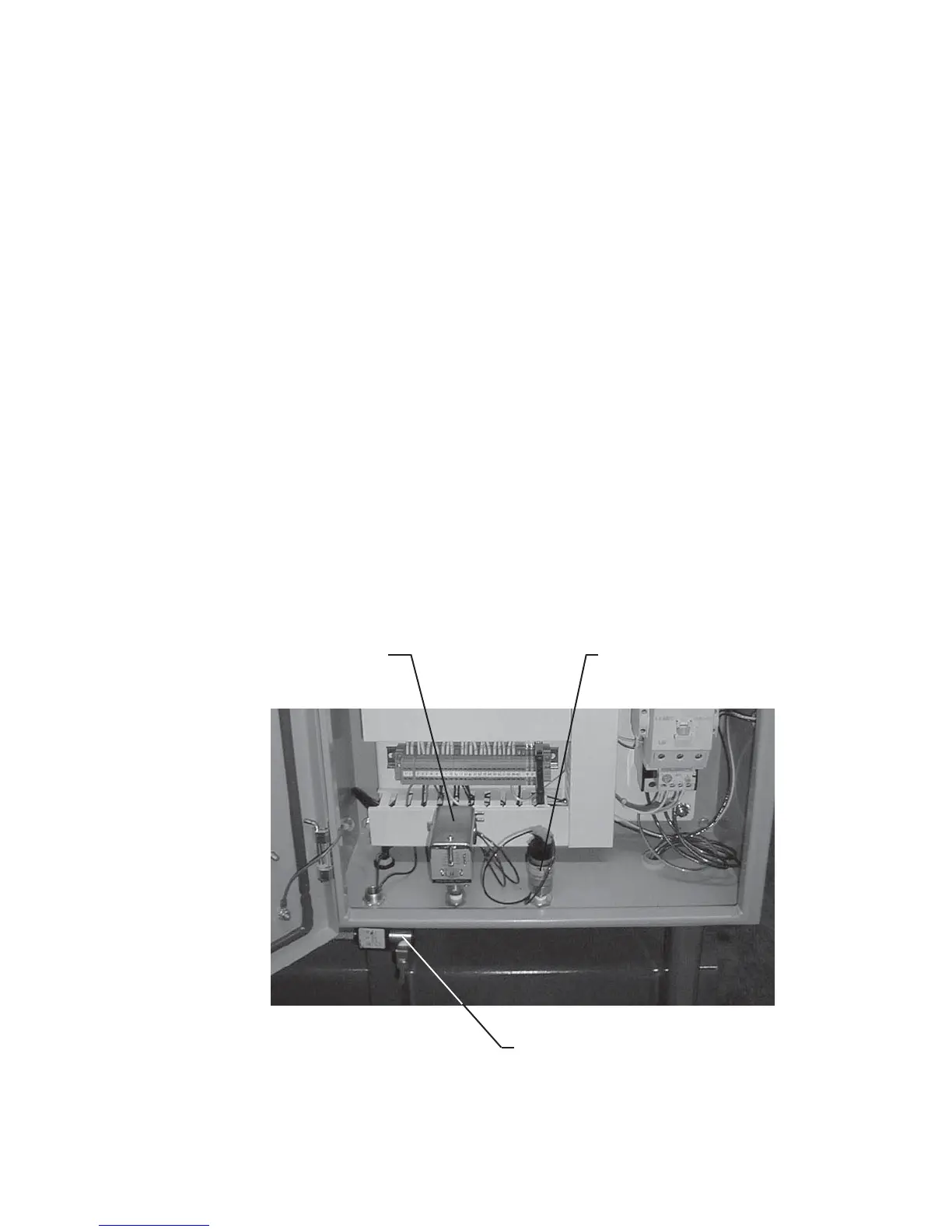

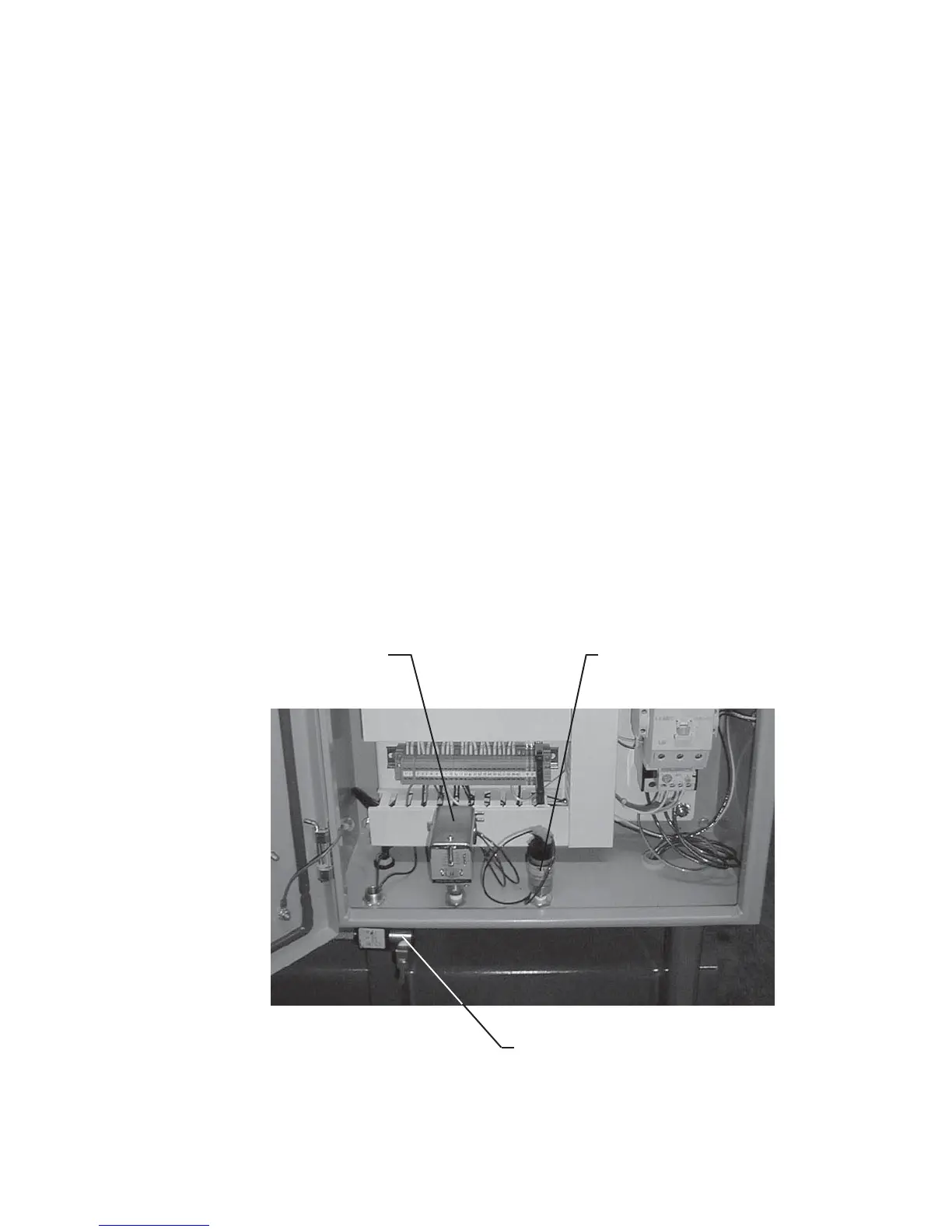

COMPRESSOR CONTROL PANEL

Your Hycomp compressor may be provided with a

factory installed compressor control panel (see Figure

6). Optional accessories specific to the control

application requirements may also be included.

A Hycomp compressor control system electrical

schematic is included, if applicable, as well as a basic

piping and instrument diagram (P&ID) for reference

by installation and operations personnel. Instructions

specific to each unique configuration of control

system is provided with the compressor. Components

generally common to many forms of compressor

control schemes require installation as follows:

Control Panel Enclosure – The enclosure must be of

appropriate NEMA rating for the application. Observe

all enclosure warnings when dealing with the enclosure

and its contents. Follow proper UL and NEMA codes

Figure 6: Control Panel Instrument Connection Points

Loading...

Loading...